Welcome to the world of electronic product development in Altium's world-class electronic design software. This tutorial will help you get started by taking you through the entire process of designing a simple PCB - from idea to outputs files. If you are new to Altium software, it is worth reading the Exploring Altium Designer page to learn more about the interface, information on how to use panels, and an overview of managing design documents.

To learn more about a command, dialog, object or panel, press F1 when the cursor is over that item.

The Design

Copy Link

Copied

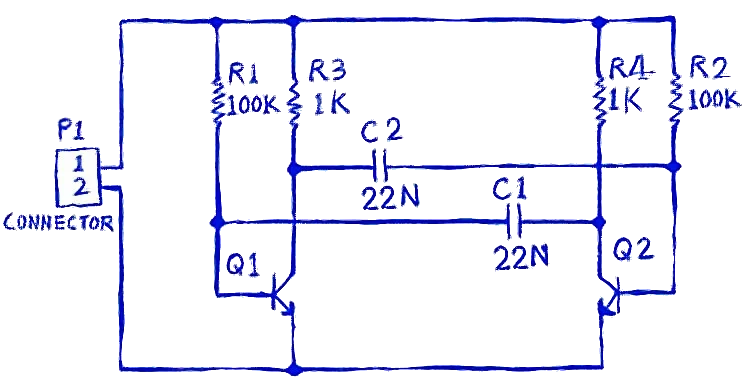

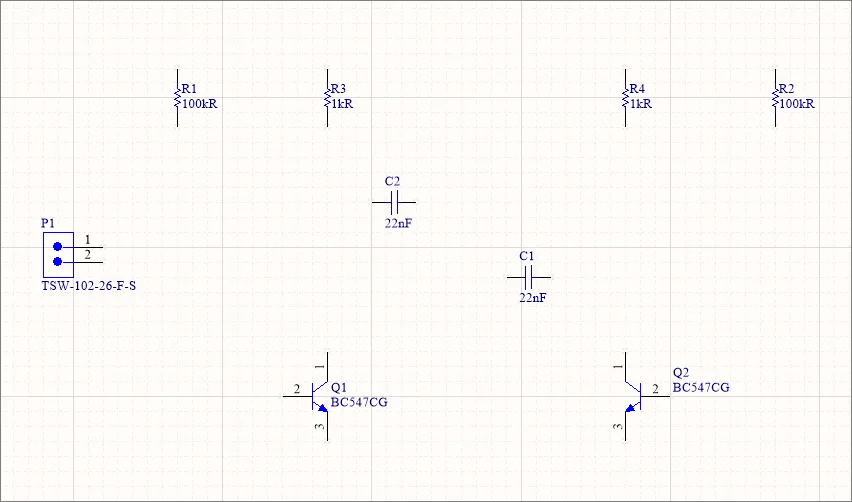

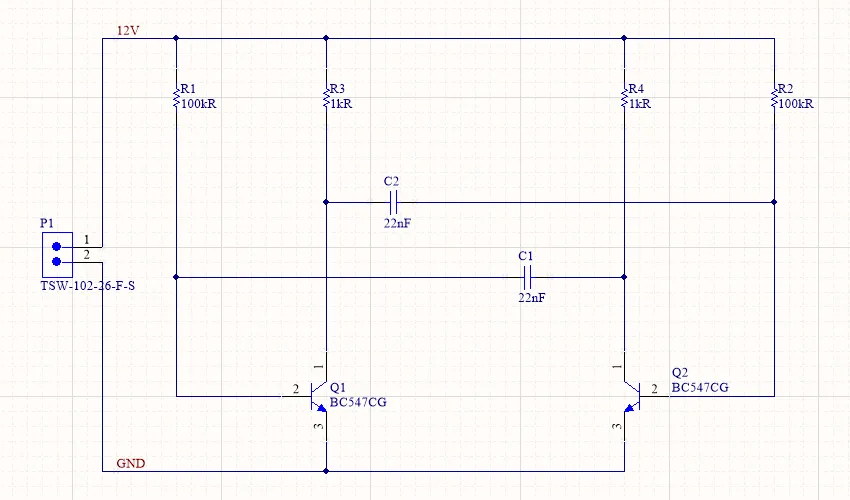

The design for which you will be creating the schematic and designing a printed circuit board (PCB) is a simple astable multivibrator. The circuit is shown below; it uses two general purpose NPN transistors configured as a self-running astable multivibrator.

Circuit for the multivibrator.

You're ready to begin capturing (drawing) the schematic. The first step is to create a PCB project.

Creating a New PCB Project

Copy Link

Copied

In Altium's electronic design software, a PCB project is the set of design documents (files) required to specify and manufacture a printed circuit board. The project file, for example, Multivibrator.PrjPCB, is an ASCII file that lists the documents in the project as well as other project-level settings, such as the required electrical rule checks, project preferences, and project outputs, such as print and CAM settings.

A new project is created by running the File » New » Project command to open the Create Project dialog.

Creating a new project

Copy Link

Copied

- Select File » New » Project from the menus.

- The Create Project dialog will open:

- Select

Local Projects in the list of Locations.

- Confirm that the Project Type is

PCB <Default>.

- Enter a suitable name as the Project Name.

- Select a suitable Folder location to store the project. A folder of the same name as the project will automatically be created in this location, and the project file will be saved in it.

- Click Create to close the dialog and create the project.

- The project will appear in the Projects panel. If this panel is not displayed, click the

button at the bottom right of the main design window, and select Project from the menu that appears.

button at the bottom right of the main design window, and select Project from the menu that appears.

- Select File » Save Project from the menus to open the Windows Save As dialog. Use the dialog to navigate to a suitable location, and enter the name

Multivibrator in the File Name field. The file extension does not need to be typed in, as it will be added automatically.

Adding a Schematic to the Project

Copy Link

Copied

The next step is to add a new schematic sheet to the project.

Add a schematic sheet to the project, name and save the schematic, and save the project.

Adding a schematic

Copy Link

Copied

- Right-click on the project filename in the Projects panel then select Add New to Project » Schematic, as shown in the image above. A blank schematic sheet named

Sheet1.SchDoc will open in the design window and an icon for this schematic will appear linked to the project in the Projects panel under the Source Documents folder icon.

- To save the new schematic sheet, select File » Save As (or use the right-click context menu). The Save As dialog will open, ready to save the schematic in the same location as the project file. Type the name Multivibrator in the File Name field and click Save (there is no need to type in the extension). Note that files stored in the same folder as the project file itself (or in a child/grandchild folder) are linked to the project using relative referencing, whereas files stored in a different location are linked using absolute referencing.

- Since you have added a schematic to the project, the project file also has changed. Right-click on the project filename in the Projects panel then select Save to save the project.

When the blank schematic sheet opens, you will notice that the workspace changes. The menu bar includes new items and a bar with buttons becomes visible - you are now in the Schematic Editor. Each editor presents its own set of menus and panels, and supports it own set of shortcut keys.

An entire set of floating panel(s) can be closed using the  icon at the top right of the panel, and an individual panel can be closed by right-clicking on its name. When needed, a panel can be reopened via the

icon at the top right of the panel, and an individual panel can be closed by right-clicking on its name. When needed, a panel can be reopened via the  button at the bottom right of the application. Alternatively, press the F4 shortcut to hide/display all floating panels.

button at the bottom right of the application. Alternatively, press the F4 shortcut to hide/display all floating panels.

Setting the Document Options

Copy Link

Copied

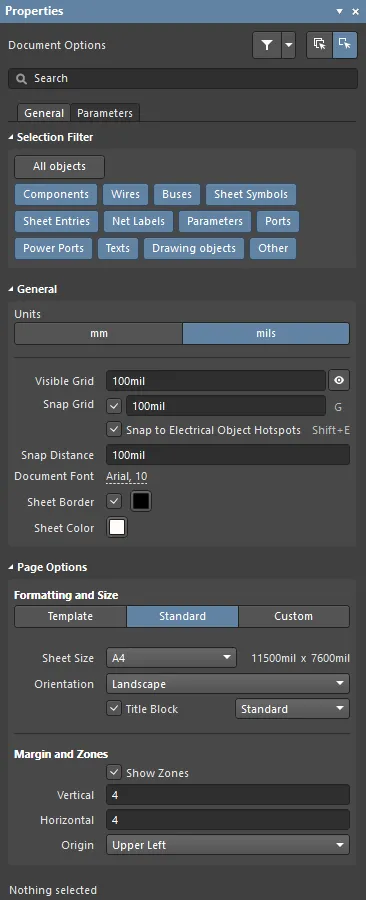

Panel page: Schematic Document Options

Before you start drawing your circuit, it's good to set up the appropriate document options, including the Sheet Size, and the Snap and Visible grids.

Document options are configured for each schematic sheet, set the sheet size as required.

As well as the technique described in the collapsible section below, the Document Options properties can also be accessed by double-clicking in the sheet border.

Environment options, such as the cursor type, selection color and autopan behavior, are configured in the Preferences dialog (Tools » Preferences).

Configuring the Document Options

Copy Link

Copied

The properties of most objects, including the schematic sheet (or PCB workspace), are configured in the Interactive Properties panel. The panel automatically displays the properties of the selected object, or if no object is selected, it displays the properties of the schematic sheet (or PCB workspace).

- If the Properties panel is not visible, click the

button at the bottom right of the application and select Properties from the menu that appears.

button at the bottom right of the application and select Properties from the menu that appears.

- In Document Options mode (when nothing is selected), the panel is divided into the following sections: Selection Filter, General and Page Options. Each section can be opened/collapsed via the small triangle next to the section name.

- For this tutorial, the only change we need to make here is to set the sheet size to A4; this is done in the Page Options section.

- Confirm that both the Snap and Visible Grids are set to 100mil.

- To make the document fill the viewing area, select View » Fit Document (shortcut: V, D).

- Save the schematic by selecting File » Save (shortcut: F, S).

To learn more about any of the controls in the Properties panel, press F1 when the cursor is over the panel.

Accessing the Components

Copy Link

Copied

Related article: More about Components and Libraries

The real-world component that gets mounted on the board is represented as a schematic symbol during design capture, and as a PCB footprint for board design.

Components can be:

- Placed directly from the Manufacturer Part Search panel. This panel gives you instant and up-to-date access to a powerful component search and aggregation system, detailing millions of components from thousands of manufacturers, each with real-time supply chain information. Many of the components are design-ready, complete with a symbol and a footprint model; these parts will include the

icon in the panel.

icon in the panel.

- Created in and placed from local file libraries, or your company's Managed Content Server. These components are searched for and placed through the Components panel. More on this approach in the Working with Your Own Components section below.

- For this tutorial, all of the parts will be sourced from the Manufacturer Part Search panel.

- Throughout the tutorial, the terms component and part are both used to describe the design components you will be placing and wiring.

Searching for New Parts

Main article: Manufacturer Part Search panel

Your go-to location to find new components is the Manufacturer Part Search panel. To open the Manufacturer Part Search panel, click the  button at the bottom right of the application then select Manufacturer Part Search from the menu (show me). Panels that are currently visible are marked with a check in the menu.

button at the bottom right of the application then select Manufacturer Part Search from the menu (show me). Panels that are currently visible are marked with a check in the menu.

The first time the Manufacturer Part Search panel is opened, it will display a list of component Categories, as shown below.

The Manufacturer Part Search panel, before performing a search.

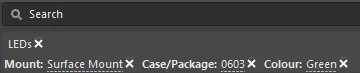

Utilizing Altium Designer's advanced component search engine, the Manufacturer Part Search panel can be used in a straightforward search mode by entering a query in the main Search field, or in its advanced faceted mode by progressively refining the search criteria using the Categories and Filters choices – or by using both capabilities together.

- To perform a straightforward search, type a search description into the Search field at the top of the panel.

For example: LED green clear 0603 SMD

Use the Search field to perform a text-based search.

- Or to perform a faceted search, use the Categories and Filters to explore potential parts by toggling criteria on and off.

For example:

- First select a Category, such as

LEDs,

- then Filter the LEDs category by the

Color, Case/Package, Mount, Has Model, and so on.

Or use a combination of the Categories, Filters, and the Search field to perform a faceted search.

Tips for working in the Manufacturer Part Search panel

Copy Link

Copied

- Categories are accessed using the drop-down, indicated by Number 1 in the image above.

- Click the

button to toggle the Filters list on and off (Number 2 in the image). The contents of the Filters list changes to suit the category of component being searched.

button to toggle the Filters list on and off (Number 2 in the image). The contents of the Filters list changes to suit the category of component being searched.

- Some of the Filter fields include text boxes to enter numeric values. Press Enter on the keyboard to apply the value.

- If the results list does not update, click in the Search field and press Enter on the keyboard.

- The current search criteria defined by the chosen Category and enabled Filters list are detailed just below the search bar. Click the small x icon to remove any of the existing search criterion.

- Click on a column heading to sort the results by that column.

- Right-click on an existing column heading to access the Select Columns dialog (

![]() show me).

show me).

Panels and dialogs that support searching for components have a landscape mode and a portrait mode. As the panel/dialog is resized the controls will re-arrange, so they may not present exactly as they are shown and described here.

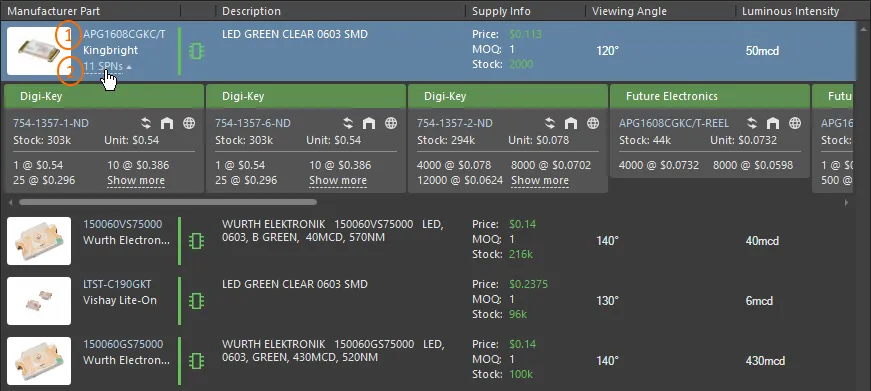

Exploring the Search Results

The search results region of the panel displays a list of manufacturer parts which wholly or partly match the search criteria. Click on a part to select it and display a link giving access to up-to-date supply chain information about that part.

Tips for working with the search results

Copy Link

Copied

- If the manufacturer provides an image of the part, it will be displayed. Next to the image is the Manufacturer Part Number (MPN), which is also link to detailed information about the part on the Octopart website (indicated by the number 1 in the image above).

- The vertical colored bar indicates the manufacturer's Lifecycle status; for example, Volume Production, EOL, etc. Hover the cursor over the bar for more information. Note that the manufacturer's Lifecycle status is not an indication of availability; that is displayed in the individual supplier tiles (as described below). For example, a manufacturer might have a part flagged as End of Life, but suppliers might still have large amounts of stock.

► Learn more about Interpreting the Manufacturer Lifecycle State.

- Click anywhere on a row to select that part. The row will highlight and a second link will appear indicating the number of suppliers who can deliver that part (number 2 in the image above). Click the link to display detailed supply chain information about the suppliers that carry that part, ordered by availability and price.

- Each Supplier's details about that part are presented on a tile with a colored banner. These tiles are also referred to as SPNs (Supplier Part Numbers). Details about the icons and information in each tile is given below.

- Click the panel's

button to configure: the currency used, if invalid SPNs should be excluded (display only suppliers that show suitable stock levels and up-to-date data), or configure the available suppliers.

button to configure: the currency used, if invalid SPNs should be excluded (display only suppliers that show suitable stock levels and up-to-date data), or configure the available suppliers.

Understanding the Supplier Tile

There is a large amount of information presented in each SPN tile. Hover the cursor over an icon or detail to display a tooltip with more information.

The SPN tile includes detailed information about the part and its availability.

The SPN tile includes detailed information about the part and its availability.

Understanding the information in the SPN Tile

Copy Link

Copied

- Tile banner showing the Supplier name where the banner color indicates:

- Green = Best choice

- Orange = Acceptable

- Red = Risky

- Supplier part number (links to that part on the Supplier's website).

- Last updated icon; the color indicates:

- Light Gray = Default, updated less than one week ago

- Orange = 1 week < last update < month ago

- Red = last update > 1 month ago

- Country code for the Supplier location (ISO alpha 2); colored red if unknown.

- Part source.

- Stock quantity; red if no stock available.

- Unit price, red if no price available. Unit price includes currency icon; currency is determined by the location of the supplier.

- Available price breaks, with Minimum Order Quantities.

Working with your own Components

Copy Link

Copied

At some point you will need to create your own components and store them locally. There are essentially two types of components that can be created:

- Managed components - components are created and stored in a Managed Content Server.

► Learn more about managed components

- Unmanaged components - components are created and stored in Altium-format library files. These are referred to as file-based libraries, or file libraries.

► Learn more about file-based components and libraries

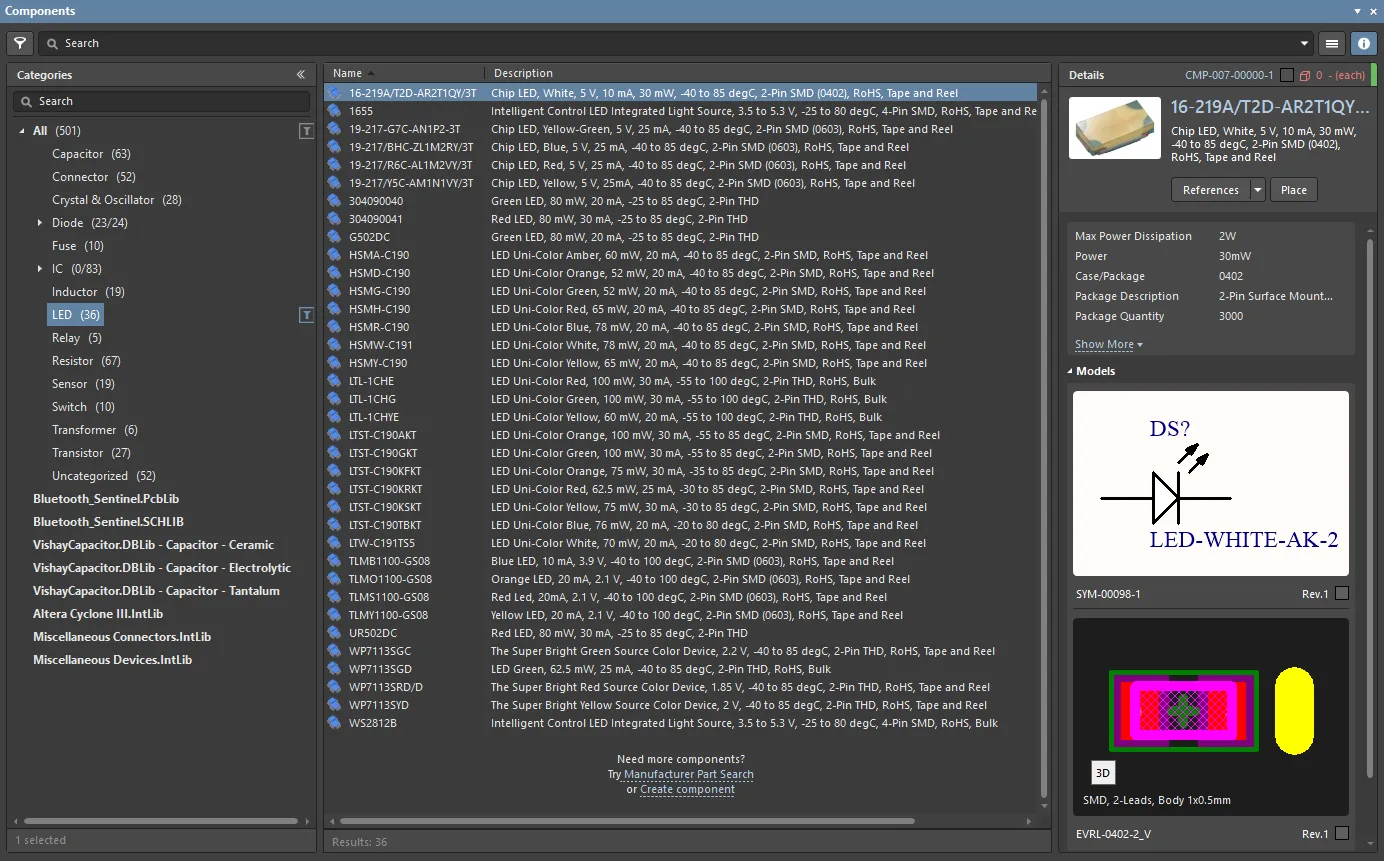

Both managed and unmanaged components are browsed, searched for and placed in the Components panel. Like the Manufacturer Part Search panel, the Components panel supports string-based searching, faceted searching, or a combination of both. Use the  button to display the Components panel.

button to display the Components panel.

Components panel being used to browse components stored in a managed content server.

In this tutorial, all of the components will be placed from the Manufacturer Part Search panel. The information in this section is included to give you a basic overview of how to work with unmanaged components.

Working with Unmanaged Components

Copy Link

Copied

Storing Unmanaged File-based Components

The following file-based component storage options can be used with Altium Designer:

| Library Type |

Function |

| Schematic Library |

Schematic component symbols are created in schematic libraries (*.SchLib), which are stored locally. Each symbol can become a component by adding links to a PCB footprint, then adding component parameters to detail the component's specifications. |

| PCB Library |

PCB footprints (models) are stored in PCB libraries (*.PcbLib), which are stored locally. The footprint includes the electrical elements, such as the pads, as well as the mechanical elements, such as the component overlay, dimensions, glue dots, and so on. It can also include a 3D definition, created by placing 3D Body objects, or by importing a STEP model. |

| Library Package / Integrated Library |

As well as working directly from the schematic and PCB libraries, you can also compile the component elements into an integrated library (*.IntLib, stored locally). Doing this results in a single, portable library which holds all the models and symbols. An integrated library is compiled from a Library package (*.LibPkg), which is essentially a special-purpose project file, with the source schematic (*.SchLib) and PCB libraries (*.PcbLib) added to it as source documents. As part of the compilation process, you can also check for potential problems, such as missing models and mismatches between schematic pins and PCB pads. |

| Altium database library |

An intermediate database library file (DbLib) presents an external ODBC data-source as an Altium component library (each record specifies a component). The Altium models (symbol, footprint, etc) are stored in file-libraries and referenced in each database record. In the DbLib, database fields are mapped to component parameters, these are retrieved and added to the component during placement from the DbLib. |

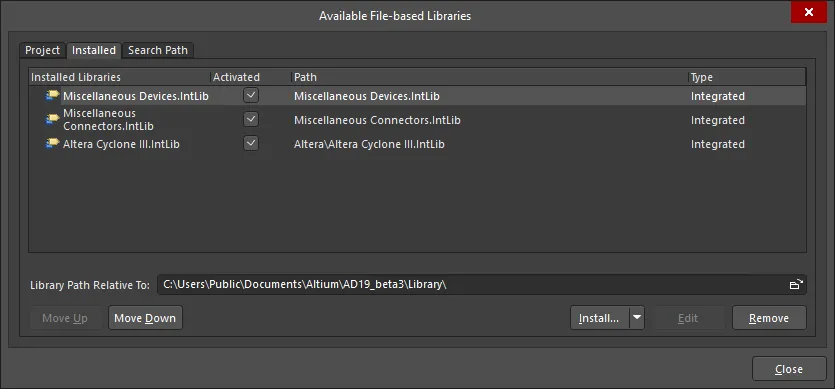

Libraries Available for Placing Unmanaged Components

Dialog page: Available File Libraries

In Altium Designer, library-based components can only be placed from available libraries. The term available libraries includes:

- Libraries in the current project - if a library is part of the project, then the components in it are automatically available for placement within that project.

- Installed libraries - these are libraries that have been installed in Altium Designer, their components are available for use in any open project.

- Libraries on a defined search path - it is also possible to define a search path to a folder that holds multiple libraries. Because all files in the search path are searched every time a new component is chosen in a panel, this approach is only recommended for small libraries that hold simple model definitions, such as simulation models. Search paths are not recommended for complex models, such as footprints that include 3D models.

Installing a File Library

Libraries are installed in the Installed tab of the Available File Libraries dialog. To open the dialog, click the  button at the top of the Components panel and select File-based Libraries Preferences from the menu.

button at the top of the Components panel and select File-based Libraries Preferences from the menu.

Install the required libraries to make their components available for designs.

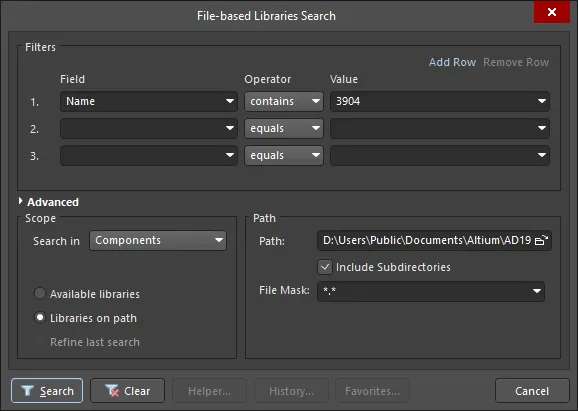

Advanced Searching in File-Libraries

To help find a component in both installed and not-installed libraries, Altium Designer includes a library searching feature.

Searching is performed in the File-based Libraries Search dialog, which is accessed by clicking the  button on the Components panel, and selecting File-based Libraries Search from the menu. The upper half of the dialog is used to define what you are searching for, the lower half is used to define where to search.

button on the Components panel, and selecting File-based Libraries Search from the menu. The upper half of the dialog is used to define what you are searching for, the lower half is used to define where to search.

Search across installed libraries (Available libraries), or libraries on the hard drive (Libraries on path).

- The Scope of the search is libraries that are:

- already installed (Available libraries), or

- in libraries located in on the hard drive (Libraries on Path). The Path is set to point to the folder holding the file libraries, for example the supplied libraries are stored in

C:\Users\Public\Documents\Altium\Altium Designer <Version>\Library.

- Click the Search button to begin the search. The results are displayed in the Components panel as the search takes place.

- You can only place components from file-libraries that are installed in the software, if you attempt to place from a library that is not currently installed you will be asked to Confirm the installation of that library when you attempt to place the component.

Library searching is actually performed using queries. In the File-based Libraries Search dialog, switch to the Advanced mode to examine the query. Hover the cursor over the image above to show the search dialog in Advanced mode.

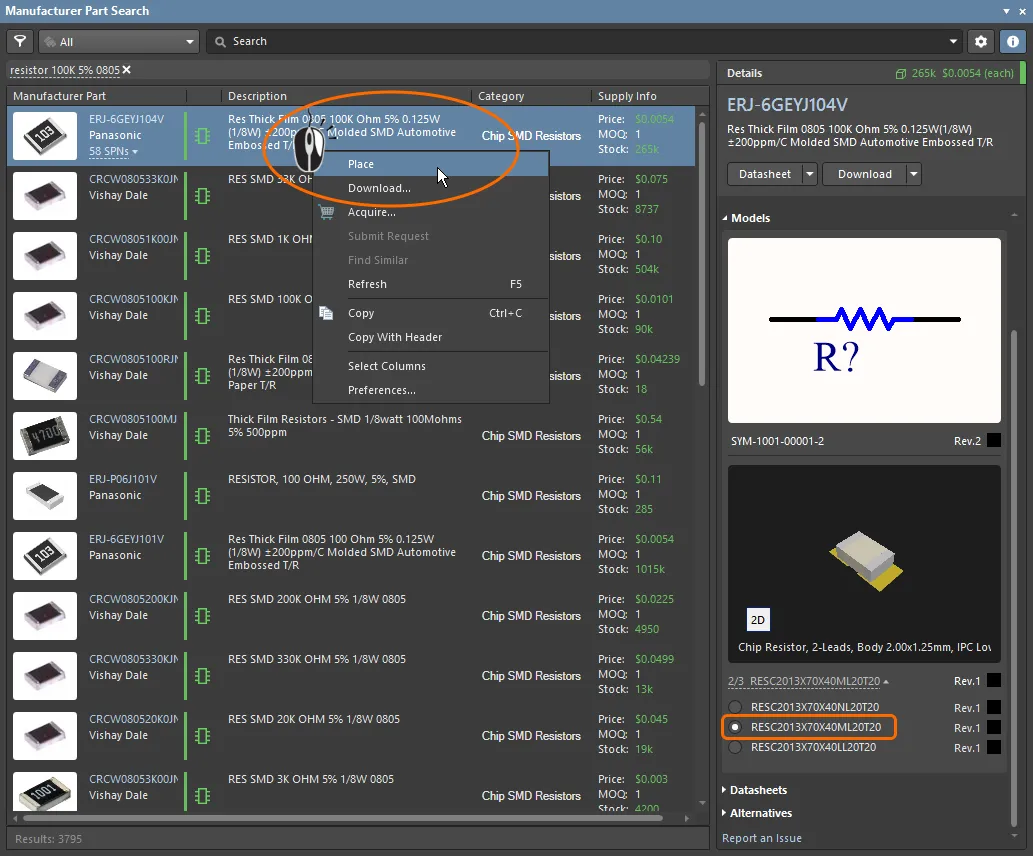

Placing from the Manufacturer Part Search Panel onto the Schematic

Copy Link

Copied

If a component that you have found in the Manufacturer Part Search panel has Altium design models, it will display the  icon. If a component has models, the schematic symbol and footprint models will be listed in the Details region of the panel (click the

icon. If a component has models, the schematic symbol and footprint models will be listed in the Details region of the panel (click the  button in the panel to display this region). This component can be placed directly from the panel onto the current schematic sheet.

button in the panel to display this region). This component can be placed directly from the panel onto the current schematic sheet.

Use the faceted search features in the Manufacturer Part Search panel to only display components with models.

Use the faceted search features in the Manufacturer Part Search panel to only display components with models.

The Filters region of the panel includes a Has Model filter. Enable this to only display design-ready parts. Click  to display the available filters.

to display the available filters.

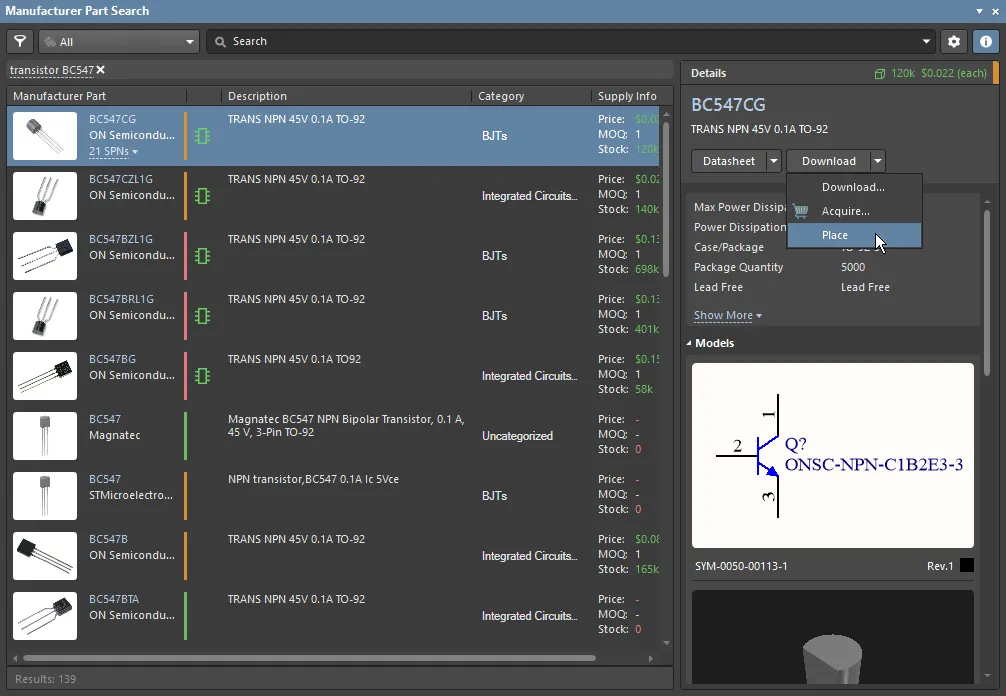

To place a component from the panel, you can:

-

![]() Select Place from the Download button - the cursor automatically moves to be within the bounds of the schematic sheet and the component appears floating on the cursor; position it and click to place. After placing a component, another instance of the same component will appear on the cursor; right-click to drop out of placement mode.

Select Place from the Download button - the cursor automatically moves to be within the bounds of the schematic sheet and the component appears floating on the cursor; position it and click to place. After placing a component, another instance of the same component will appear on the cursor; right-click to drop out of placement mode.

- Right-click on the component and select Place from the context menu. The component appears floating on the cursor; position it and click to place. Note that if the Manufacturer Part Search panel is floating over the workspace, it will fade to allow you to see the schematic and place the component. After placing a component, another instance of the same component will appear on the cursor; right-click to drop out of placement mode.

- Click and drag - click and drag the component from the grid region of the panel onto this sheet. This mode requires that the cursor is held down; the component is placed when the cursor is released. Using this technique only one component is placed. After placing the component, you are free to select another component or another command.

Placement Tips

While the component is floating on the cursor, you can:

- Press Spacebar to rotate it counterclockwise in 90 degree increments.

- Press X to flip it along the X-axis; press Y to flip it along the Y-axis.

- Press Tab to display the Properties panel and edit the properties of an object prior to placement. The values entered become the defaults. If the designator has the same prefix, it will be auto-incremented.

- During component placement, the software will automatically pan if you touch the window edge. Autopanning is configured in the Schematic - Graphical Editing page of the Preferences dialog. If you accidentally pan beyond where you want, while the component is floating on the cursor you can:

- Ctrl+Wheel Roll to zoom out and in again, or

- right-click and drag to slide the schematic around, or

- Ctrl+PgDn to display the entire sheet again.

- If the Manufacturer Part Search panel is floating over the schematic sheet when you place a part, it will automatically become transparent whenever the cursor+component gets close to it. The transparency of floating panels is configured in the System - Transparency page of the Preferences dialog. Alternatively, all floating panels can be hidden/displayed at any time (while running a command or not) by pressing the F4 shortcut.

► Learn more about Schematic Placement and Editing Techniques

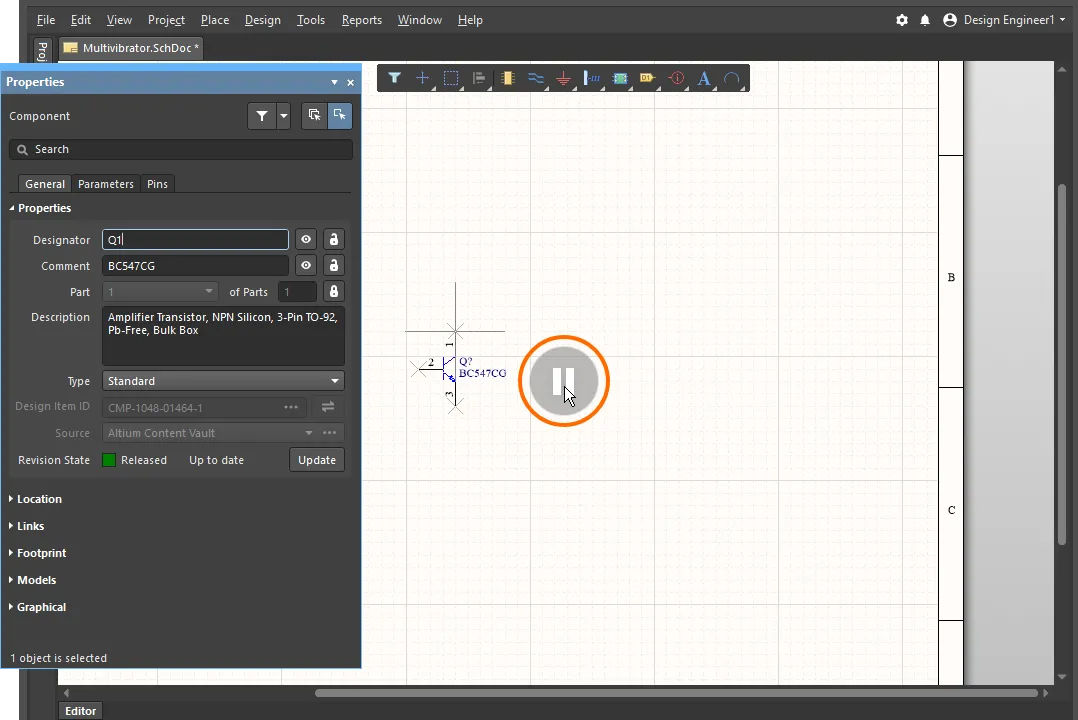

Working with the Properties panel during Placement

During object placement, if you press Tab the editing process will pause and the interactive Properties panel will open. The default behavior is for the most commonly edited field to be highlighted, ready for editing. Because the editing process is paused, you can use the cursor (or press Tab on the keyboard) to move to another field in the panel.

When you have finished editing, click the Pause button (  ) as shown in the image below to return to object placement. Alternatively, press Enter to finish object editing and return to object placement.

) as shown in the image below to return to object placement. Alternatively, press Enter to finish object editing and return to object placement.

Editing is paused when you press Tab during placement - click the Pause icon on the screen to return to placing the component.

Placing the Multivibrator Parts

Copy Link

Copied

Now, it is time to use the Manufacturer Part Search panel to find the components needed for the Multivibrator circuit as listed in the following table.

| Designator |

Description |

Comments |

| Q1, Q2 |

General purpose NPN transistor, eg BC547 or 2N3904 |

Search for: transistor BC547, chose BC547CG |

| R1, R2 |

100K resistor, 5%, 0805 |

Search for: resistor 100K 5% 0805

Note that the search also returns other values in the Filters section of the panel; 100kΩ can be enabled in the Resistance section. |

| R3, R4 |

1K resistor, 5%, 0805 |

Search for: resistor 1K 5% 0805

Note that the search also returns other values in the Filters section of the panel; 1kΩ can be enabled in the Resistance section. |

| C1, C2 |

22nF capacitor, 10%, 16V, 0805 |

Search for: capacitor 22nF 16V 0603 |

| P1 |

2-pin header, thruhole |

Use the faceted search feature to filter for a 2-pin vertical male header |

Once you have placed the components, the schematic should look like the image below.

You can proceed to find and place the components. Note that the collapsible sections below include tips on editing during placement, which is more efficient than editing after placement. If you choose to leave the editing until after the components are placed, click to select the component and edit it in the Properties panel.

All the components have been placed, ready for wiring.

Finding and Placing the Transistors

Copy Link

Copied

- Select View » Fit Document (shortcut: V, D) to ensure your schematic sheet takes up the full editing window.

- Using the search techniques just described, use the Manufacturer Part Search panel to

![]() search for:

search for: transistor BC547 .

- Display the information section of the panel so that you can explore the properties and models of the selected component. You will be choosing a component that includes a symbol and footprint.

- To explore the availability of a component, select it in the panel then

![]() click the SPN link that appears.

click the SPN link that appears.

- Click to select the required transistor in the results grid in the panel then click the Download drop-down (as shown below) and select Place. The cursor will change to a cross hair and you will have an image of the transistor floating on your cursor. You are now in part placement mode. If you move the cursor around, the transistor will move with it.

Do not place the transistor yet!

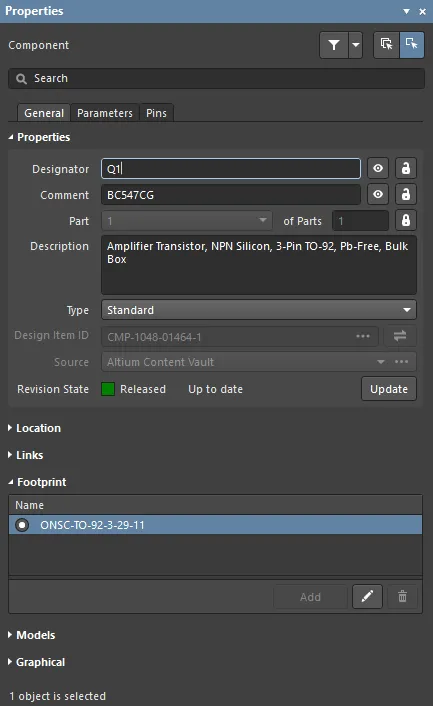

- Before placing the part on the schematic, you can edit its properties, which can be done for any object floating on the cursor. While the transistor is still floating on the cursor, press the Tab key to open the Properties panel. The default behavior is to automatically highlight the most-used field in the panel, ready for editing; in this case it will be the Designator. Note that each section of the panel can be individually expanded or collapsed, which means your panel might look different.

Set the Designator to Q1, and the Comment to be visible.

- In the Properties section of the panel, type in the Designator

Q1.

- Confirm that the visibility control for the Comment field is set to visible (

).

).

- Leave all other fields at their default values then click the Pause button (

) to return to part placement.

) to return to part placement.

- Move the cursor, with the transistor symbol attached, to position the transistor a little to the left of the middle of the sheet. Note the current snap grid, which is displayed on the left of the Status bar at the bottom of the application. It defaults to 100mil; you can press the G shortcut to cycle through the available grid settings during object placement. It is strongly advised to keep the snap grid at 100mil or 50mil to keep the circuit neat and make it easy to attach wires to pins. For a simple design such as this, 100mil is a good choice.

- Once you are happy with the transistor's location, left-mouse click or press Enter on the keyboard to place the transistor onto the schematic. The location can be changed later, if required.

- Move the cursor and you will find that a copy of the transistor has been placed on the schematic sheet, and you are still in part placement mode with the transistor outline floating on the cursor. This feature allows you to place multiple parts of the same type.

- You are ready to place the second transistor. This transistor is the same as the previous one so there is no need to edit its attributes before you place it. The software will automatically increment the component designator when you place multiple instances of the same part. In this case, the next transistor will automatically be designated Q2.

- If you refer to the schematic diagram shown above, you will notice that Q2 is drawn as a mirror of Q1. To horizontally flip the orientation of the transistor floating on the cursor, press the X key on the keyboard. This flips the component along the X axis.

- Move the cursor to position the part to the right of Q1. To position the component more accurately, press the PgUp key twice to zoom in two steps. You should now be able to see the grid lines.

- Once you have positioned the part, left-mouse click or press Enter to place Q2. Once again a copy of the transistor you are "holding" will be placed on the schematic and the next transistor will be floating on the cursor ready to be placed.

- Since both of the transistors have been placed, exit part placement mode by clicking the right-mouse button or pressing the Esc key. The cursor will revert back to a standard arrow.

Finding and Placing the Capacitors

Copy Link

Copied

- Return to the Manufacturer Part Search panel and search for:

capacitor 22nF 16V 0603. The search will return a number of potential capacitors; the components that have models will be listed first.

- Select a capacitor in the search result grid (that has models), right-click on it and select Place from the context menu.

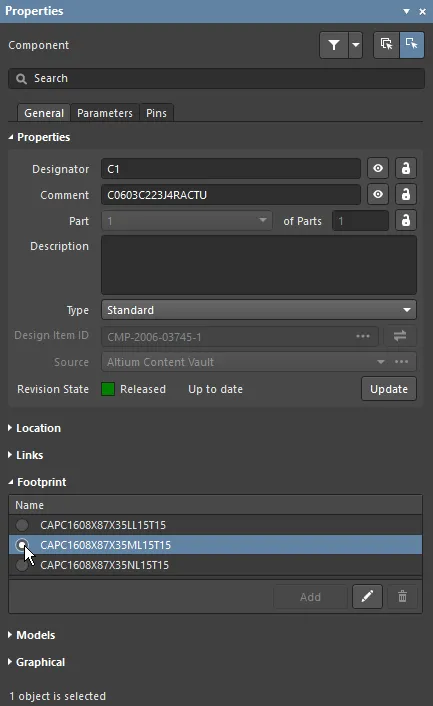

- While the capacitor is floating on the cursor, press the Tab key to open the Properties panel.

- In the Properties section of the panel, type in the Designator

C1.

- Confirm that the visibility control for the Comment field is set to visible.

- Expand the Footprint section of the Properties panel. Many of the resistors and capacitors have three footprint models: IPC Low Density (

M), IPC Medium Density (N), and IPC High Density (L). If you compare the footprint names, they will be identical except for the letter indicating density. Select the M variety as shown in the image below.

- Leave the other fields at their default values and click the Pause button (

) to return to part placement; the capacitor will be floating on the cursor.

) to return to part placement; the capacitor will be floating on the cursor.

- Press the Spacebar to rotate the component in 90° increments until it has the correct orientation.

- Position the capacitor above the transistors (refer to the schematic diagram shown earlier) and click the left mouse button or press Enter to place the part.

- Position and place capacitor C2.

- Right-click or press Esc to exit placement mode.

- The default parameters for the capacitor may be only the manufacturer name and part number, but any of the parameters shown in the Manufacturer Part Search panel can be added to the placed capacitors. To check the current parameters, double-click on one of the capacitors to open the Properties panel then click on the Parameters tab at the top of the panel.

- If the list of Parameters does not include the capacitance and voltage, return to the Manufacturer Part Search panel, confirm that the same capacitor is still selected, then click the Show More link to show the complete list of available parameters. Using the Windows Ctrl+click selection technique, select the following parameters (if available):

Capacitance, Case/Package, Tolerance, and Voltage Rating.

- Right-click on any of the selected parameters and select Add Parameters to Part from the context menu.

- The cursor will change to a crosshair; left-click once on each capacitor in turn to add the selected parameters. If you find it difficult to position the cursor over the center of the capacitor symbol, hold the Ctrl key down to temporarily inhibit the snap grid.

- Confirm that the

![]() parameters have been added to both C1 and C2.

parameters have been added to both C1 and C2.

Finding and Placing the Resistors

Copy Link

Copied

- In the Manufacturer Part Search panel, search for:

resistor 100K 5% 0805. The search will return a number of potential resistors (including resistors with other values); the components that have models will be listed first.

- Select a suitable 100K resistor in the search result grid (that has models), and display the footprint in the Models section of the panel.

- Many of the resistors and capacitors have three footprint models: IPC Low Density (

M), IPC Medium Density (N), and IPC High Density (L). If you compare the footprint names, they will be identical except for the letter indicating density. Select the M variety as shown in the image below. This selection can be done before the component is placed on the schematic during schematic placement or after schematic placement.

- Right-click on the resistor in the search results grid and select Place from the context menu, as shown below.

- While the resistor is floating on the cursor, press the Tab key to open the Properties panel.

- In the Properties section of the panel, type in the Designator

R1.

- Leave all other fields at their default values and click the Pause button (

) to return to part placement; the resistor will be floating on the cursor.

) to return to part placement; the resistor will be floating on the cursor.

- Press the Spacebar to rotate the component in 90° increments until it has the correct orientation.

- Position the resistor above and to the left of the base of Q1 (refer to the schematic diagram shown previously) and click the Left Mouse Button or press Enter to place the part.

- Next, place the other 100k resistor, R2, above and to the right of the base of Q2. The designator will automatically increment when you place the second resistor.

- Exit part placement mode by clicking the Right Mouse Button or pressing the Esc key. The cursor will revert back to a standard arrow.

- The default parameters for the resistor may be only the manufacturer name and part number, but any of the parameters shown in the Manufacturer Part Search panel can be added to the placed resistors. To check the current parameters, double-click on one of the 100K resistors to open the Properties panel, then click on the Parameters tab at the top of the panel.

- If the list of Parameters does not include the resistance, return to the Manufacturer Part Search panel. Confirm that the same resistor is still selected, then click the Show More link to show the complete list of available parameters. Using the Windows Ctrl+click selection technique, select the following parameters (if available):

Case/Package, Resistance, and Tolerance.

- Right-click on any of the selected parameters and select Add Parameters to Part from the context menu.

- The cursor will change to a crosshair; left-click once on each resistor in turn to add the selected parameters.

- Confirm that the

![]() parameters have been added to both R1 and R2. The visibility of the Resistance parameter will be changed shortly.

parameters have been added to both R1 and R2. The visibility of the Resistance parameter will be changed shortly.

- The remaining two resistors, R3 and R4, have a value of 1K; search for:

resistor 1K 5% 0805 in the Manufacturer Part Search panel. The search will return a number of potential resistors (including resistors with other values). The components that have models will be listed first.

- Select a suitable 1K resistor in the search result grid (that has models), and display the footprint in the Models section of the panel.

- Many of the resistors and capacitors have three footprint models: IPC Low Density (

M), IPC Medium Density (N), and IPC High Density (L). If you compare the footprint names, they will be identical except for the letter indicating density; select the M variety.

- Right-click on the resistor in the search results grid and select Place from the context menu.

- While the resistor is floating on the cursor, press the Tab key to open the Properties panel.

- In the Properties section of the panel, type in the Designator

R3.

- Leave all other fields at their default values and click the Pause button (

) to return to part placement; the resistor will be floating on the cursor.

) to return to part placement; the resistor will be floating on the cursor.

- Press the Spacebar to rotate the component in 90° increments until it has the correct orientation.

- Position and place R3 directly above the Collector of Q1, then place R4 directly above the Collector or Q2, as shown in the image above.

- Right-click or press Esc to exit part placement mode.

- Using the same process as described for R1 and R2; add the

Case/Package, Resistance, and Tolerance parameters to R3 and R4.

- The last step is to configure the visibility of the Parameters. This can be done for all four resistors at the same time. To select all of the resistors, drag the selection rectangle from right to left to select touching (demonstrated in the animation below).

- On the General tab of the Properties panel, disable the visibility of the Comment parameter (demonstrated in the animation below).

- On the Parameters tab of the Properties panel, enable the visibility of the Resistance parameter (demonstrated in the animation below).

- Re-position the Resistance string to a suitable location. When a string is being moved, the snap grid can be temporarily disabled by holding down the Ctrl key. Alternatively, rotating any schematic component(s) (Ctrl+Spacebar) automatically sets all visible strings to their default locations (demonstrated in the animation below).

Finding and Placing the Connector

Copy Link

Copied

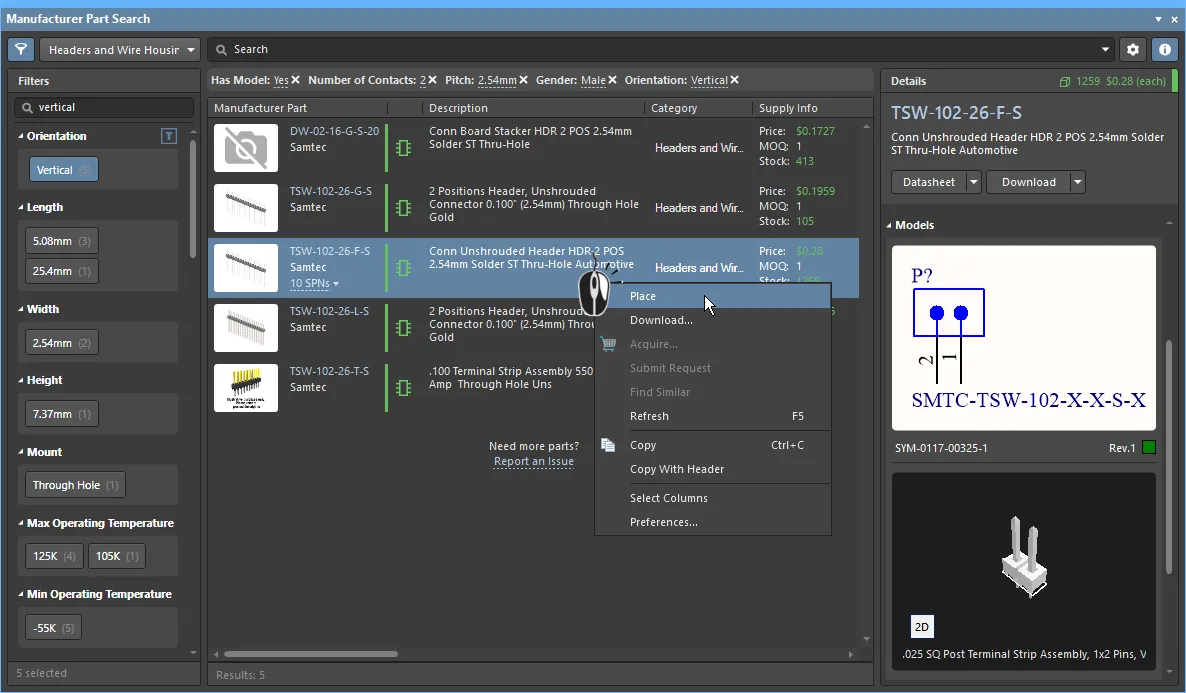

- The last component to find is the 2-pin header. Return to the Manufacturer Part Search panel. This time you will use the panel's faceted searching capabilities.

- In the Categories drop-down, select Headers and Wire Housings under Connectors.

- Click the Filters button (

) to display the Filters column.

) to display the Filters column.

- The list of available filters is dynamically updated to suit the category being used, and can be quite long. To help manage it, only the most commonly-used filters are displayed. Scroll to the bottom of the list and click the

link to display all of the available filters.

link to display all of the available filters.

- An efficient way of working with the filters is to use the Search field at the top. Searching returns strings that match in either the Filter Name or in the Filter Settings. Using the following search terms, apply the filters and select the options listed below:

| Search for |

Choose |

has model |

Has Model: Yes |

contacts |

Number of Contacts: 2 |

pitch |

Pitch: 2.54mm |

male |

Gender: Male |

vertical |

Orientation: Vertical |

- A small number of 2-pin vertical male headers should be returned, as shown below. Select a suitable 2-pin connector, such as the

Samtec TSW-102-26-F-S or the Samtec TSW-102-26-G-S, from the search results; right-click on it and select Place from the menu.

- While the header is floating on the cursor, press Tab to edit the attributes and set the Designator to

P1.

- Before placing the header, press Spacebar to rotate it to the correct orientation. Click to place the connector on the schematic, as shown in the image above.

- Right-click or press Esc to exit part placement mode.

- Save your schematic.

Editing in the Properties Panel

One of the powerful features of the Properties panel is that is supports editing multiple selected objects at the same time.

- If all objects share a property, that property will be available for editing.

- If all objects share the same property value, that value will be displayed.

- If objects share the same property but have different values, it will display an asterisk (*).

- The value entered or option chosen is applied to all selected objects.

Use the Properties panel to edit the properties of multiple selected objects. The selected components are rotated to force their strings to the default locations.

Use the Properties panel to edit the properties of multiple selected objects. The selected components are rotated to force their strings to the default locations.

You have now placed all the components. Note that the components shown in the image above are spaced so that there is plenty of room to wire to each component pin. This is important because you cannot place a wire across the bottom of a pin to get to a pin beyond it. If you do, both pins will connect to the wire. If you need to move a component, click-and-hold on the body of the component then drag the mouse to reposition it.

Component Positioning Tips

- To reposition any object, place the cursor directly over the object, click-and-hold the left mouse button, drag the object to a new position then release the mouse button. Movement is constrained to the current snap grid, which is displayed on the Status bar. Press the G shortcut at any time to cycle through the current snap grid settings. Remember that it is important to position components on a coarse grid, such as 50 or 100mil.

- Once a component has been placed on the schematic, the software will attempt to maintain connectivity (keep the wires attached) if the component is moved. This connective-aware movement is referred to as dragging. To move the component without maintaining connectivity, hold Ctrl as you click and drag the component. To switch the default behavior from dragging to moving, disable the Always Drag option in the Schematic - Graphical Editing page of the Preferences dialog.

- Because the schematic editor defaults to always dragging, Spacebar cannot be used to rotate a placed component. To rotate a placed component, press Ctrl+Spacebar.

- You can also re-position a group of selected schematic objects using the arrow keys on the keyboard. Select the objects then press an arrow key while holding down the Ctrl key. Hold Shift as well to move objects by 10 times the current snap grid.

- The grid can also be temporarily set to 1 while moving an object with the mouse; hold Ctrl to do this. Use this feature when positioning text.

- The grids you cycle through when you press the G shortcut are defined in the Schematic - Grids page of the Preferences dialog (Tools » Preferences). The Units controls on the Schematic - General page of the Preferences dialog are used to select the measurement units; select either Mils or Millimeters. Note that Altium components are designed using the an imperial grid; if you change to a metric grid, the component pins will no longer fall onto a standard grid. Because of this, it is recommended to use Mils for Units unless you plan on only using your own components.

Wiring up the Circuit

Copy Link

Copied

Wiring is the process of creating connectivity between the various components of your circuit. To wire up your schematic, refer to the sketch of the circuit and the animation shown below .

Use the Wiring tool to wire up your circuit. Toward the end of the animation, you can see how wires can be dragged.

The Active Bar

The tools most commonly used in each editor are available on the Active Bar, which is displayed at the top of the editing window.

The buttons on the Active Bar are either single-function or multi-function. Multi-function buttons are indicated by a small triangle. Click and hold anywhere on the button for one second. A menu will appear listing other available commands. The last-used command will become the default for that button location.

Wiring the schematic

Copy Link

Copied

- To make sure you have a good view of the schematic sheet, press the PgUp key to zoom in or PgDn to zoom out. Alternatively, hold down the Ctrl key and roll the mouse wheel to zoom in/out, or hold Ctrl + Right Mouse button down and drag the mouse up/down to zoom in/out. There are also a number of useful View commands in the right-click View submenu, such as Fit All Objects (Ctrl+PgDn).

- First, wire the lower pin of resistor R1 to the base of transistor Q1 in the following manner. Click the

button on the Active Bar (Place » Wire, or Ctrl+W shortcut) to enter the wire placement mode. The cursor will change to a cross hair.

button on the Active Bar (Place » Wire, or Ctrl+W shortcut) to enter the wire placement mode. The cursor will change to a cross hair.

- Position the cursor over the bottom end of R1. When you are in the right position, a red connection marker (red cross) will appear at the cursor location. This indicates that the cursor is over a valid electrical connection point on the component.

- Left-click or press Enter to anchor the first wire point. Move the cursor and you will see a wire extend from the cursor position back to the anchor point.

- Position the cursor over the base of Q1 until you see the cursor change to a red connection marker. If the wire is forming a corner in the wrong direction, press Spacebar to toggle the corner direction.

- Click or press Enter to connect the wire to the base of Q1. The cursor will release from that wire.

- Note that the cursor remains a cross hair indicating that you are ready to place another wire. To exit placement mode completely and go back to the arrow cursor, you would Right-Click or press Esc again - but don't do this just now.

- Next, wire from the lower pin of R3 to the collector of Q1. Position the cursor over the lower pin of R3 and click or press Enter to start a new wire. Move the cursor vertically until it is over the collector of Q1 then click or press Enter to place the wire segment. Again, the cursor will release from that wire and you remain in wiring mode, ready to place another wire.

- Wire up the rest of your circuit, as shown in the animation above.

- When you have finished placing all the wires, right-click or press Esc to exit placement mode. The cursor will revert to an arrow.

Wiring Tips

- Use the Ctrl+W shortcut to launch the Place » Wire command.

- Left-click or press Enter to anchor the wire at the cursor position.

- Press Backspace to remove the last anchor point.

- Press Spacebar to toggle the direction of the corner. You can observe this in the animation shown above toward the end when the connector is being wired.

- Press Shift+Spacebar to cycle through the wiring corner modes. Available modes include: 90, 45, Any Angle and Autowire (place orthogonal wire segments between the click points).

- Right-click or press Esc to exit wire placement mode.

- Click and hold to drag the component together with any connected wires; Ctrl + click and hold to move a placed component. .

- Whenever a wire crosses the connection point of a component, or is terminated on another wire, a junction will automatically be created.

- A wire that crosses the end of a pin will connect to that pin even if you delete the junction. Check that your wired circuit looks like the figure shown before proceeding.

- Wiring cross-overs can be displayed as a small arch if preferred. Enable the option in the Schematic - General page of the Preferences dialog.

Nets and Net Labels

Each set of component pins that you have connected to each other now form what is referred to as a net. For example, one net includes the base of Q1, one pin of R1 and one pin of C1. Each net is automatically assigned a system-generated name, which is based on one of the component pins in that net.

To make it easy to identify important nets in the design, you can add Net Labels to assign names. For the multivibrator circuit, you will label the 12V and GND nets in the circuit, as shown below.

Net Labels have been added to the 12V and GND nets, completing the schematic.

Adding net labels

Copy Link

Copied

Net Labels, Ports and Power Ports

- As well as giving a net a name, Net Labels are also used to create connectivity between two separate points on the same schematic sheet.

- Ports are used to create connectivity between two separate points on different sheets. Offsheet connectors can also be used to do this.

- Power Ports are used to create connectivity between points on all sheets; for this single sheet design, Net Labels or Power Ports could have been used.

Congratulations! You have just completed your first schematic capture. Before you turn the schematic into a circuit board, you need to configure the project options and check the design for errors.

Setting Up Project Options

Copy Link

Copied

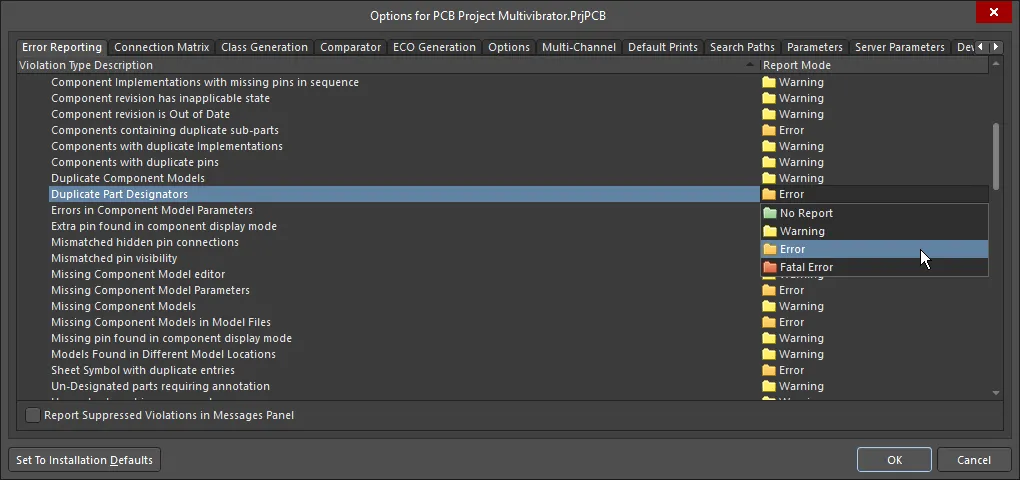

Project-specific settings are configured in the Project Options dialog shown below (Project » Project Options). The project options include the error checking parameters, a connectivity matrix, Class Generator, the Comparator setup, ECO generation, output paths and connectivity options, Multi-Channel naming formats, Default Print setups, Search Paths, and project-level Parameters. These settings are used when you compile the project.

Project outputs, such as assembly, fabrication outputs and reports can be set up from the File and Reports menus. These settings are also stored in the Project file so they are always available for this project. An alternate approach is to use an OutputJob file to configure the outputs, with the advantage that an OutputJob can be copied from one project to the next. See More About Outputs to learn more configuring the outputs.

Compiling the Project

After you complete the schematic, you compile it. This generates an internal connectivity map of the design, detailing all of the components and nets. When the project is compiled, comprehensive design and electrical rules are also applied to verify the design. The design and rule checks are configured in the Project Options dialog.

Refer to the Creating Connectivity and the Compiling and Verifying the Design pages to learn more.

When all errors are resolved, the compiled schematic design is ready to be transferred to the target PCB document by generating a series of Engineering Change Orders (ECOs). Underlying this process is a comparator engine that identifies every difference between the schematic design and the PCB, and generates an Engineering Change Order (ECO) to resolve each difference. This approach of using a comparator engine to identify differences means you not only work directly between the schematic and PCB (there is no intermediate netlist file used), it also means the same approach can be used to synchronize the schematic and PCB at any stage during the design process. The comparator engine also allows you to find differences between source and target files and update (synchronize) in both directions. The ECO generation and comparator are also configured in the Project Options dialog.

Refer to the Design Synchronization page to learn more.

Checking the Electrical Properties of Your Schematic

Schematic diagrams are more than just simple drawings - they contain electrical connectivity information about the circuit. You can use this connectivity awareness to verify your design. When you compile a project, the software checks for errors according to the rules set up in the Error Reporting and Connection Matrix tabs of the Project Options dialog. When you compile the project, any violations that are detected will display in the Messages panel.

Setting up the Error Reporting

Dialog page: Error Reporting

The Error Reporting tab in the Project Options dialog is used to set up a large range of drafting and component configuration checks. The Report Mode settings show the level of severity of a violation. If you want to change a setting, click on a Report Mode next to the violation you want to change and choose the level of severity from the drop-down list.

Configure the Error Reporting tab to detect for design errors when the project is compiled .

Configuring the Error Checking

Copy Link

Copied

- Select Project » Project Options to open the Options for PCB Project dialog.

- Scroll through the list of error checks and note that they are clustered in groups; each group can be collapsed if required.

- Click on the Report Mode setting for any error check and note the options available.

Setting Up the Connection Matrix

Dialog page: Connection Matrix

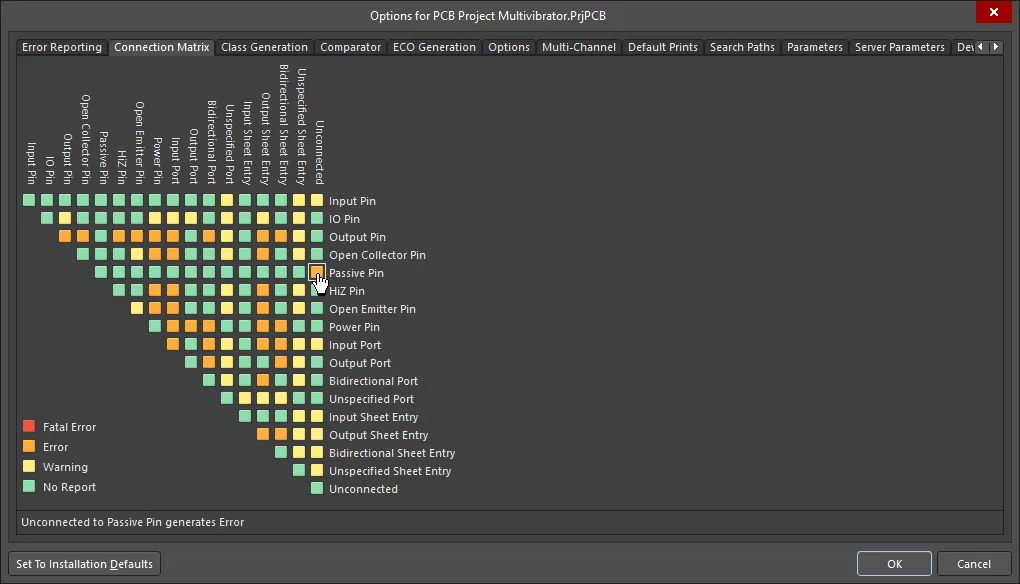

When the design is compiled, a list of the pins in each net is built into memory. The type of each pin is detected (e.g., input, output, passive, etc.,), then each net is checked to see if there are pin types that should not be connected to each other, for example, an output pin connected to another output pin. The Connection Matrix tab of the Project Options dialog is where you configure what pin types are allowed to connect to each other. For example, look at the entries on the right side of the matrix diagram and find Output Pin. Read across this row of the matrix until you get to the Open Collector Pin column. The square where they intersect is orange, indicating that an Output Pin connected to an Open Collector Pin on your schematic will generate an error condition when the project is compiled.

You can set each error type with a separate error level, i.e. from No Report to a Fatal Error. Click on a colored square to change the setting; continue to click to move to the next check-level. Set the matrix so that Unconnected - Passive Pin generates an Error, as shown in the image below.

The Connection Matrix tab defines what electrical conditions are checked for on the schematic; note that the Unconnected - Passive Pin setting is being changed.

Changing the Connection Matrix

Copy Link

Copied

- To change one of the settings, click the colored box; it will cycle through the four possible settings. Note that you can right-click on the dialog face to display a menu that lets you toggle all settings simultaneously, including an option to restore them all to their Default state (handy if you have been toggling settings and cannot remember their default state).

- Your circuit contains only passive pins. Let's change the default settings so that the connection matrix detects unconnected passive pins. Look down the row labels to find the Passive Pin row. Look across the column labels to find Unconnected. The square where these entries intersect indicates the error condition when a passive pin is found to be unconnected in the schematic. The default setting is green indicating that no report will be generated.

- Click on this intersection box until it turns orange (as shown in the image above) so that an error will be generated for unconnected passive pins when the project is compiled. You will purposely create an instance of this error later in the tutorial.

Configuring the Class Generation

Dialog page: Class Generation

The Class Generation tab in the Project Options dialog is used to configure what type of classes are generated from the design (the Comparator and ECO Generation tabs are then used to control if classes are transferred to the PCB). By default, the software will generate Component classes and Rooms for each schematic sheet, and Net Classes for each bus in the design. For a simple, single-sheet design such as this, there is no need to generate a component class or a room. Ensure that the Component Classes checkbox is cleared; doing this will also disable the creation of a room for that component class.

Note that this tab of the dialog also includes options for User-Defined Classes.

The Class Generation tab is used to configure what classes and rooms are automatically created for the design.

The Class Generation tab is used to configure what classes and rooms are automatically created for the design.

Configuring Class Generation

Copy Link

Copied

- Clear the Component Classes checkbox as shown in the image above. This will automatically disable the creation of a placement room for that schematic sheet.

- There are no buses in the design so there is no need to clear the Generate Net Classes for Buses checkbox located near the top of the dialog.

- There are no user-defined Net Classes in the design (done through the placement of Net Class directives on the wires) so there is no need to clear the Generate Net Classes checkbox in the User-Defined Classes region of the dialog.

Setting Up the Comparator

Dialog page: Comparator

The Comparator tab in the Project Options dialog sets which differences between files will be reported or ignored when a project is compiled. Generally, the only time you will need to change settings in this tab is when you add extra detail to the PCB, such as design rules, and do not want those settings removed during design synchronization. If you need more detailed control, you can selectively control the comparator using the individual comparison settings.

For this tutorial, it is sufficient to confirm that the Ignore Rules Defined in PCB Only option is enabled as shown in the image below.

The Comparator tab is used to configure exactly what differences the comparison engine will check for.

The Comparator tab is used to configure exactly what differences the comparison engine will check for.

Configuring Comparator Settings

Copy Link

Copied

- For this tutorial, it is sufficient to confirm that the Ignore Rules Defined in PCB Only option is enabled as shown in the image above.

You are now ready to compile the project and check for any errors.

Compiling the Project to Check for Errors

Copy Link

Copied

Main article: Compiling and Verifying the Design

Compiling a project checks for drafting and electrical rules errors in the design documents, and details all warnings and errors in the Messages panel. You have set up the rules in the Error Checking and Connection Matrix tabs of the Project Options dialog, so are now ready to check the design.

To compile the project and check for errors, select Project » Compile PCB Project Multivibrator.PrjPcb from the main menus.

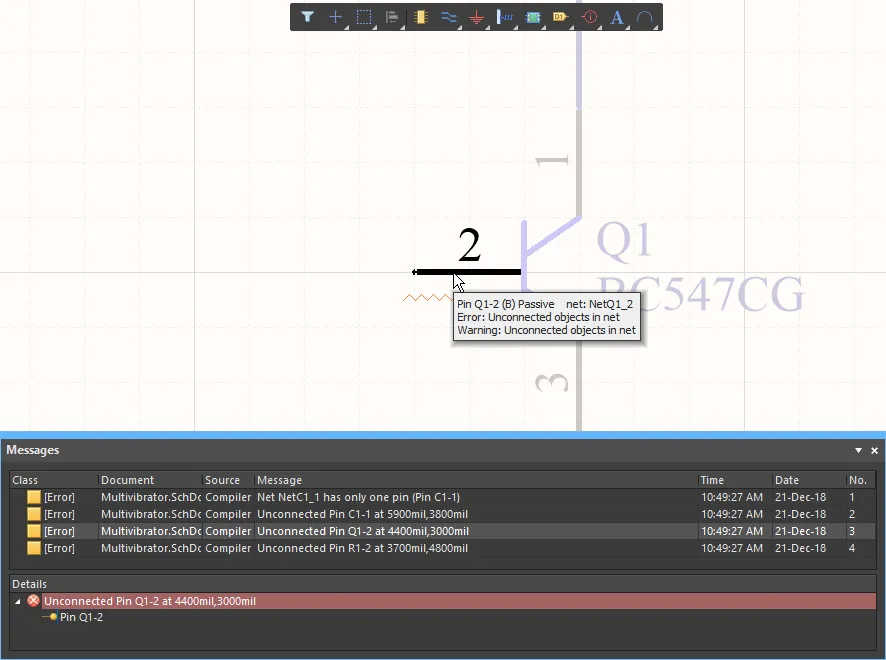

Use the Messages panel to locate and resolve design warnings and errors; double-click on a warning/error to cross probe to that object.

Compiling and checking for errors

Copy Link

Copied

- To compile the Multivibrator project, select Project » Compile PCB Project Multivibrator.PrjPcb from the main menus.

- When the project is compiled, all warnings and errors are displayed in the Messages panel. The panel will only appear automatically if there are errors detected (not when there are only warnings). To open it manually, click the

button at the bottom right and select Messages from the menu.

button at the bottom right and select Messages from the menu.

- If your circuit is drawn correctly, the Messages panel should not contain any errors, only the message Compile successful, no errors found. If there are errors, work through each one, checking your circuit and ensuring that all wiring and connections are correct.

You will now deliberately introduce an error into the circuit and recompile the project:

- Click on the Multivibrator.SchDoc tab at the top of the design window to make the schematic sheet the active document.

- Click in the middle of the wire that connects R1 to the base wire of Q1. Small, square editing handles will appear at each end of the wire and the selection color will display as a dotted line along the wire to indicate that it is selected. Press the Delete key on the keyboard to delete the wire.

- Recompile the project (Project » Compile PCB Project Multivibrator.PrjPcb) to check for errors. The Messages panel will display error messages indicating you have unconnected pins in your circuit.

- The Messages panel is divided horizontally into two regions as shown in the image above. The upper region lists all messages, which can be saved, copied, cross probed to, or cleared via the right-click menu. The lower region details the warning/error currently selected in the upper region of the panel.

- When you double-click on an error or warning in either region of the Messages panel, the schematic view will pan and zoom to the object in error.

- When you hover the cursor over the object in error (not the wiggly line), a message describing the error condition will appear.

Before you finish this section of the tutorial, let's fix the error in our schematic.

- Make the schematic sheet the active document.

- Undo the delete action (Ctrl+Z) to restore the deleted wire.

- To check that there are no longer any errors, recompile the project (Project » Recompile PCB Project Multivibrator.PrjPcb); the Messages panel should show no errors.

- Save the schematic and the project file, as well.

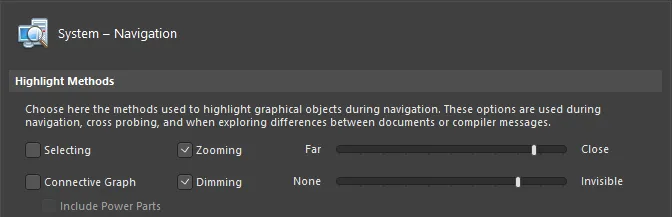

When you double-click on an error in the Messages panel:

- The schematic zooms to present the object in error. The Zoom Precision is set by the upper slider in the Highlight Methods section of the System - Navigation page of the Preferences dialog.

- The entire schematic fades except for the object in error. The amount that the schematic fades is controlled by the Dimming level, set by the lower slider in the Highlight Methods section of the System - Navigation page of the Preferences dialog. Click anywhere on the schematic to clear the dimming.

- To clear all messages from the Messages panel, right-click in the panel and select Clear All.

Schematic capture is now complete. It's time to create the PCB!

Creating a New PCB

Copy Link

Copied

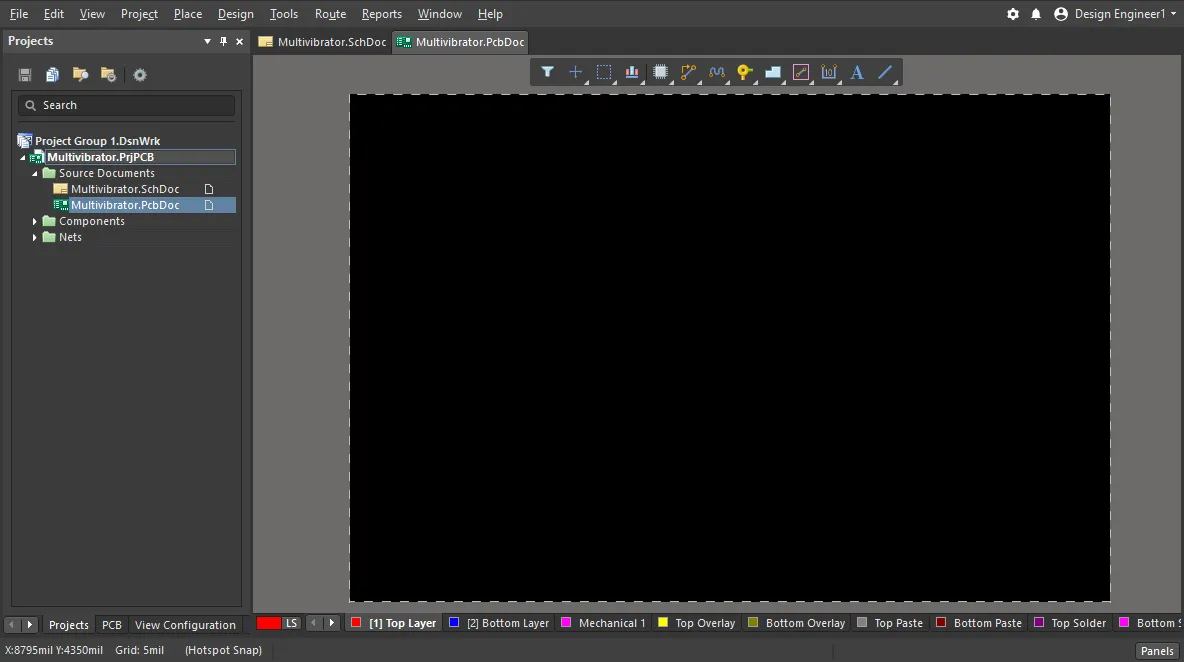

Before you transfer the design from the Schematic Editor to the PCB Editor, you need to create the blank PCB, then name and save it as part of the project.

The blank PCB has been added to the project and saved, and the project has been saved.

Adding a New Board to the Project

Copy Link

Copied

- A new PCB can be added to the project via the Projects panel right-click menu. Select the Add New to Project » PCB command.

Add a new PCB to your project.

Add a new PCB to your project.

- The PCB will appear as a Source Document in the Project as shown in the larger image above. Right-click on the PCB icon in the Projects panel to select the Save As command and name it

Multivibrator. Note that you do not need to enter the file extension in the Save As dialog; this is automatically appended.

- Adding the PCB has changed the project, so also save the project (right-click on the project filename in the Projects panel and select Save).

Configuring the Board Shape and Location

Copy Link

Copied

Main article: The Board

There are a number of attributes of this blank board that need to be changed before transferring the design from the schematic editor, including:

| Task |

Process |

| Set the origin |

The PCB editor has two origins: the Absolute Origin, which is the lower left of the workspace, and the user-definable Relative Origin, which is used to determine the current workspace location - the coordinates shown on the Status bar are relative to this origin. A common approach is to set the Relative Origin to the lower-left corner of the board shape. Select the Edit » Origin » Set command to set the Relative Origin; use the Reset command to reset it back to the Absolute Origin. |

| Set the units to Imperial or Metric |

The current workspace X / Y location and Grid are displayed on the Status bar, which is displayed along the bottom of the editor. For this tutorial, metric units will be used. To change the units, either press Q on the keyboard to toggle back and forth between Imperial and Metric units, or select the View » Toggle Units command from the menus. |

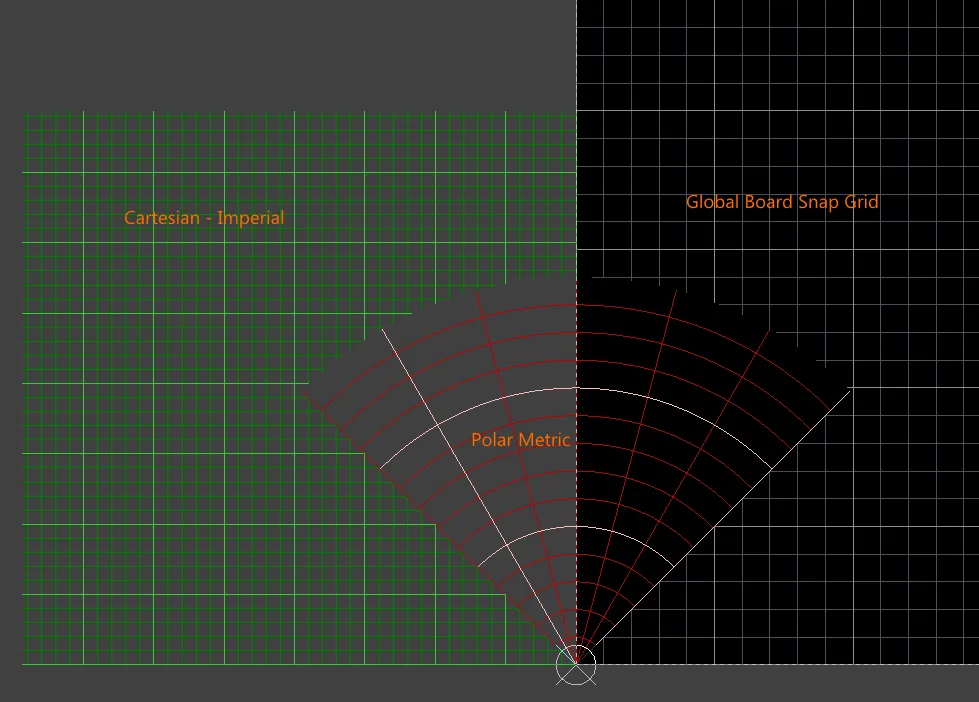

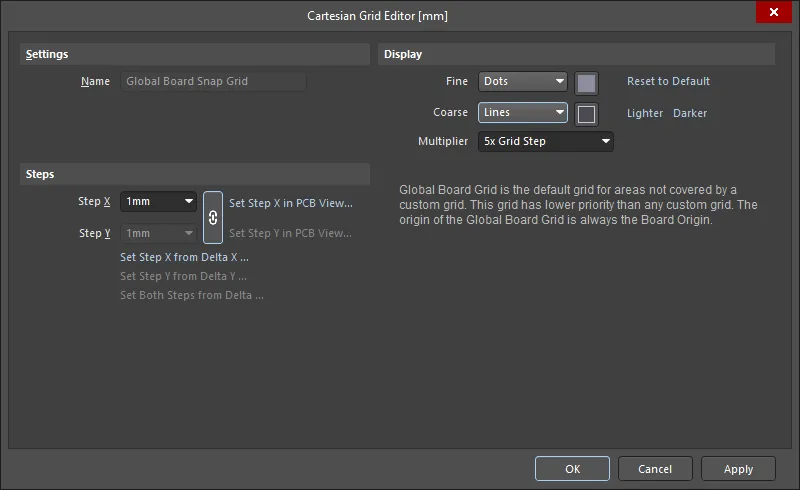

| Select a suitable snap grid |

You may have noticed that the current snap grid is 0.127mm, which is the default 5mil imperial snap grid converted to metric. To change the snap grid at any time, press G to display the Snap Grid menu, from where you can select an imperial or metric value. Note the shortcuts shown in the menu; use Ctrl+Shift+G to open the Snap Grid dialog, which is handy when you want to type in a specific value. The other useful shortcut is Ctrl+G, which opens the Cartesian Grid editor, in which you can change the grid from dots to lines, and change the grid color. Grids are discussed in more detail later in the tutorial. |

| Re-define the board shape |

The board shape is shown by the black region with a grid in it. The default size for a new board is 6x4 inches; the tutorial board is 30mm x 30mm. Details for the process of defining a new shape for the board are available below. |

| Configure the layers |

As well as the copper, or electrical layers on which you route, there are also general-purpose mechanical layers and special-purpose layers, such as the component overlays (silkscreens), solder mask, paste mask, and so on. The electrical and other layers will be configured shortly. |

- Press Ctrl+PageDown at any time to zoom to show the entire board.

- Zoom in / out using:

- PageUp / PageDown

- Ctrl+WheelRoll

- Ctrl+Right-Click&Hold+MouseDrag

Setting the Origin and the Grid

Copy Link

Copied

- There are two origins used in the software, the Absolute Origin, which is the lower left of the workspace, and the user-definable Relative Origin, which is used to determine the current workspace location. Before setting the origin, keep zooming in to the lower left of the current board shape until you can easily see the grid. To do this, position the cursor over the lower-left corner of the board shape and press PgUp until both the Coarse and Fine grids are visible as shown in the images below.

- To set the Relative Origin, select Edit » Origin » Set then position the cursor over the bottom left corner of the board shape, then left click to locate it.

Select the command, position the cursor over the lower-left corner of the board shape (left image), then click to define the origin (right image).

- The next step is to select a suitable snap grid, as discussed in the table above. During the course of design, it is quite common to change grids, for example, you might use a coarse grid during component placement, and a finer grid for routing. For this tutorial, you will be using a Metric grid. A coarse 5mm grid will be suitable for component placement. Press Ctrl+Shift+G to open the Snap Grid dialog and enter

5mm, then click OK to close the dialog.

- By entering the units as you entered a value, you have also instructed the software to switch to a Metric grid. Look at the Status bar to confirm that the Grid is now metric.

Redefining the Board Shape

Copy Link

Copied

- The default board shape is 6x4 inch; for the tutorial the board size is 30mm x 30mm.

- To zoom back out and show all of the board, select View » Fit Board from the main menus (Ctrl+PgDn).

- The board will exactly fill the PCB editor. To manipulate the size you need to be able to see the edges of the board, use Ctrl+WheelRoll to zoom out a bit more or press PgDn.

- The next step is to change the board shape. This is done in Board Planning view Mode. Select View » Board Planning Mode from the main menus to change it (shortcut: 1). The display will change; the board area will now be shown in green.

- Your choice now is to either redefine the board shape (draw it again), or edit the existing board shape. For a simple square or rectangle, it is more efficient to edit the existing board shape. To do this, select Design » Edit Board Shape from the menus. Note that you must be in Board Planning Mode for this command to be available.

For this design, it is more efficient to edit the existing board shape. These commands are only available in Board Planning Mode.

For this design, it is more efficient to edit the existing board shape. These commands are only available in Board Planning Mode.

- Editing handles will appear at each corner and the center of each edge as shown below.

Note that clicking anywhere other than on an editing handle or an edge of the shape will drop you out of board shape editing mode.

- The objective is to resize the shape to create a 30mm by 30mm board. The Coarse visible grid is 25mm (5x the snap grid), and the Fine visible grid is 5mm; these can be used as a guide. You can now either: slide the upper edge down and slide the right edge to the left to create the correct size; or move three of the corners in, leaving the one that is at the origin in its current location.

- To slide the upper edge down, position the cursor over the edge (but not over a handle). When the cursor changes to a double-headed arrow, click and hold, then drag the edge to the new location so that the Y cursor location is

30mm on the Status bar, as shown in the animation below.

- Repeat the process to move the right-hand edge in, positioning it when the X cursor location is

30mm on the Status bar.

Use the current location information at the bottom left of the Status bar to guide you as you reshape the board.

The resize cursor is shown, use the location information on the Status bar to help you as you drag the upper and right edges to resize the board to 30mm x 30mm.

The resize cursor is shown, use the location information on the Status bar to help you as you drag the upper and right edges to resize the board to 30mm x 30mm.

- Click anywhere in the workspace to drop out of board shape editing mode.

- Press the 2 shortcut to switch back to 2D Layout Mode.

- Now that the shape has been defined, you can set the grid to a value suitable for component placement, for example,

1mm. Grids are discussed in detail shortly.

- Save the board.

► Learn more about Defining the Board Shape

The board size has been defined, and the units, origin and grid have been set. The required layers will be configured shortly.

A good approach to defining the shape of a non-rectangular board is to place a series of tracks (and arcs for curved boards) on the keepout layer. As well as being useful as a placement and routing keep-away barrier, these tracks and arcs can be selected (Edit » Select » All on Layer) and used to create the board shape using the Design » Board Shape » Define from Selected Objects command.

► Learn more about Defining the Board Shape

Configuring the Defaults

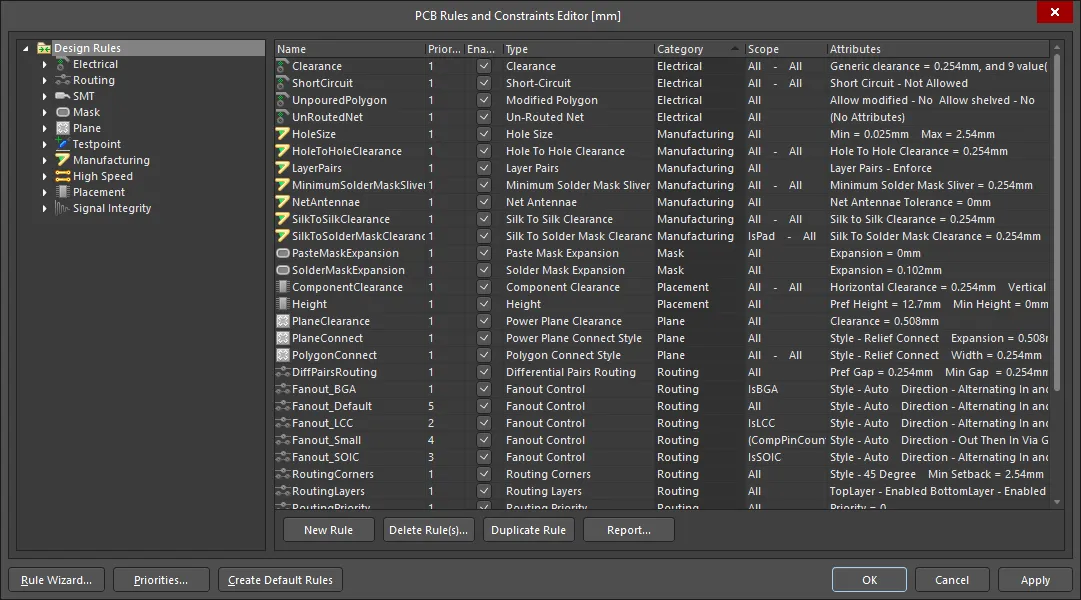

When you place an object in the PCB editor workspace, the software will define the shape and properties of the object based on:

- An applicable design rule - if there is a rule defined that applies to that object, the properties object are defined from the rule. For example, during a layer change when you are interactively routing, a via is automatically added with its size and hole size properties taken from the applicable Routing Via Style design rule.

- Default settings - if an applicable design rule does not exist or does not apply, the properties of the object are defined from the default settings configured in the PCB Editor - Defaults page of the Preferences dialog. For example, if you run the Place » Via command, the software does not know if that via will be part of a net, so it will present a via at the size defined in the defaults.

Setting the Designator and Comment defaults

Copy Link

Copied

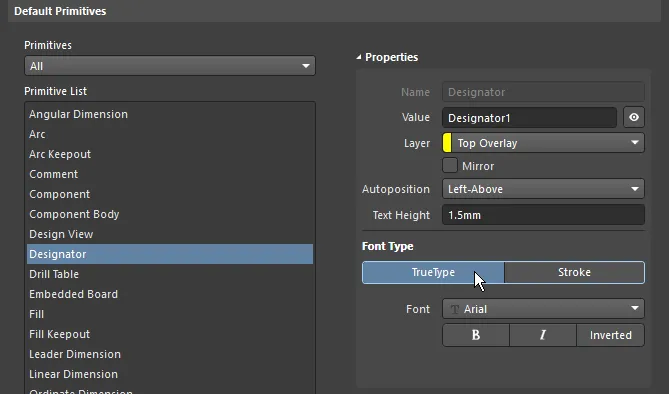

- To configure the default settings for the designator and comment strings, select Tools » Preferences to open the Preferences dialog, then open the PCB Editor - Defaults page.

- Select Designator in the Primitive List; the default Properties will be displayed. Confirm that the:

- Autoposition option is set to

Left-Above for the Designator. This is the default location in which this string is held when the component is rotated. The string can be interactively relocated at any time during the design process.

- Font Type is set to TrueType, and the Font is set to

Arial. Stroke fonts are Gerber-friendly shapes that the software can generate. TrueType gives access to all fonts available on the PC, but the font must be embedded in the PCB file if the board is to be opened on a PC that does not have that font installed (PCB Editor - True Type Fonts Preferences page).

- Text Height is set to 1.5mm for this tutorial.

- Select Comment in the Primitive List and confirm that the:

- Autoposition option is set to

Left-Below.

- Font Type is set to TrueType and the Font is set to

Arial.

- Text Height is set to 1.5mm for this tutorial.

- Comment visibility is set to hidden (

). This is a common default; component Comment strings can be selectively displayed during the design process, if required.

). This is a common default; component Comment strings can be selectively displayed during the design process, if required.

- Click OK to close the dialog.

Transferring the Design

Copy Link

Copied

Main article: Working Between the Schematic and the Board

The design is transferred directly between the schematic editor and the PCB editor; there is no intermediate netlist file created. From the schematic editor, select Design » Update PCB Document Multivibrator.PcbDoc, or from the PCB editor, select Design » Import Changes from Multivibrator.PrjPcb.

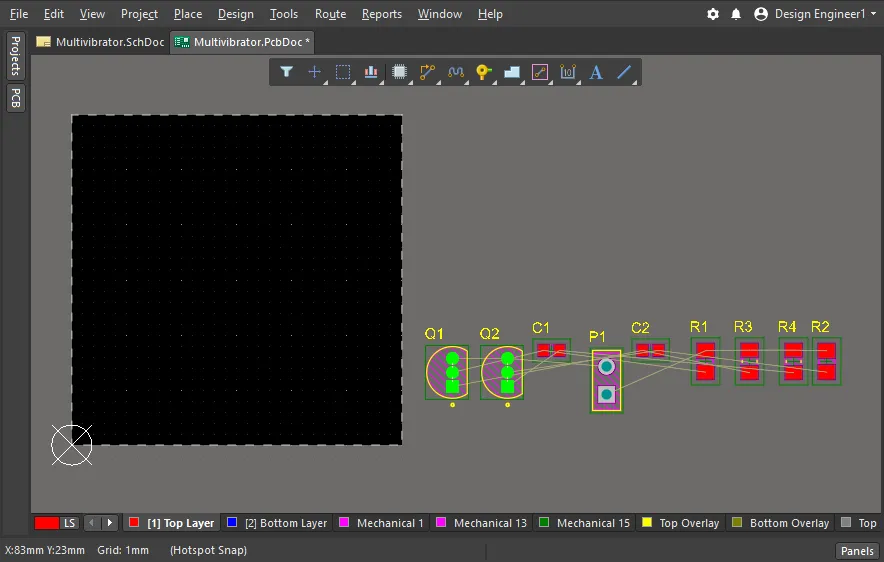

When you run either of these commands, the design is compiled and a set of Engineering Change Orders is created, which:

- List all components used in the design and the footprint required for each. When the ECOs are executed, the software will attempt to locate each footprint and place each into the PCB workspace. If the footprint is not available, an error will occur. Where the software can look for each footprint depends on: how the component was created (managed or unmanaged); and for an unmanaged component, if the PCB footprint library is currently available. All of the components have been placed from the Manufacturer Part Search panel, so the software can reference back and retrieve each footprint.

- A list of all nets (connected component pins) is created. When the ECOs are executed, the software will add each net to the PCB then attempt to add the pins that belong to each net. If a pin cannot be added, an error will occur; this most often happens when the footprint was not found or the pads on the footprint do not map to the pins on the symbol.

- Additional design data is then transferred, such as net and component classes.

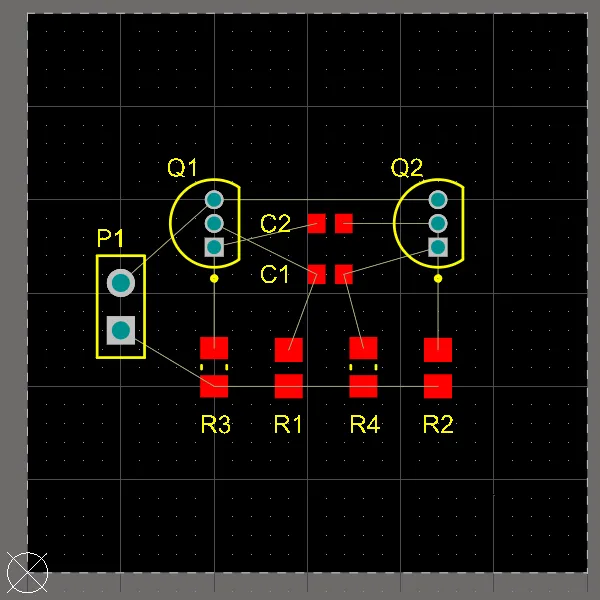

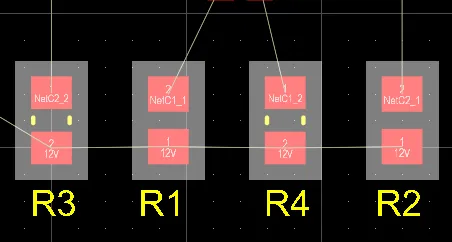

Once the ECOs have been executed, the components are placed outside the board shape and the nets are created. Note that the default Designator (and Comment) fonts have been changed.

Before transferring the schematic information to the new blank PCB, it is essential that all the related libraries for both schematic symbols and PCB footprints are available. Since all components have been placed from the Manufacturer Part Search panel (which sources symbols and footprints from a managed content server), the footprints required for the tutorial are already available.

Transferring the design from schematic capture to PCB layout

Copy Link

Copied

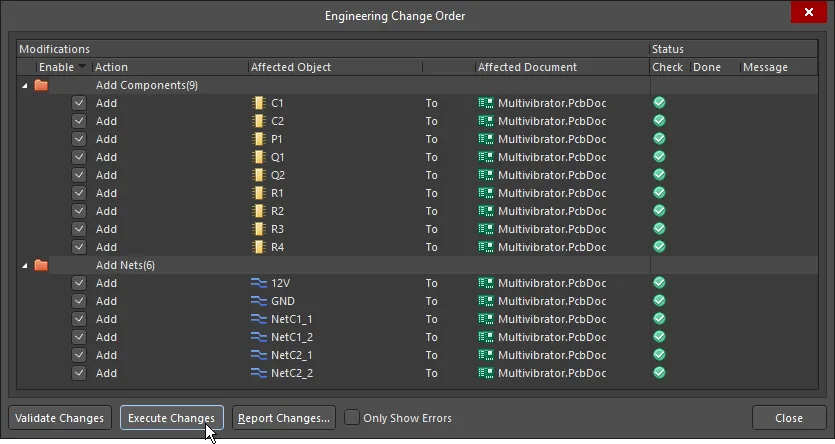

- Make the schematic document, Multivibrator.SchDoc, the active document.

- Select Design » Update PCB Document Multivibrator.PcbDoc from the Schematic editor menus. The project will compile and the Engineering Change Order dialog will open.

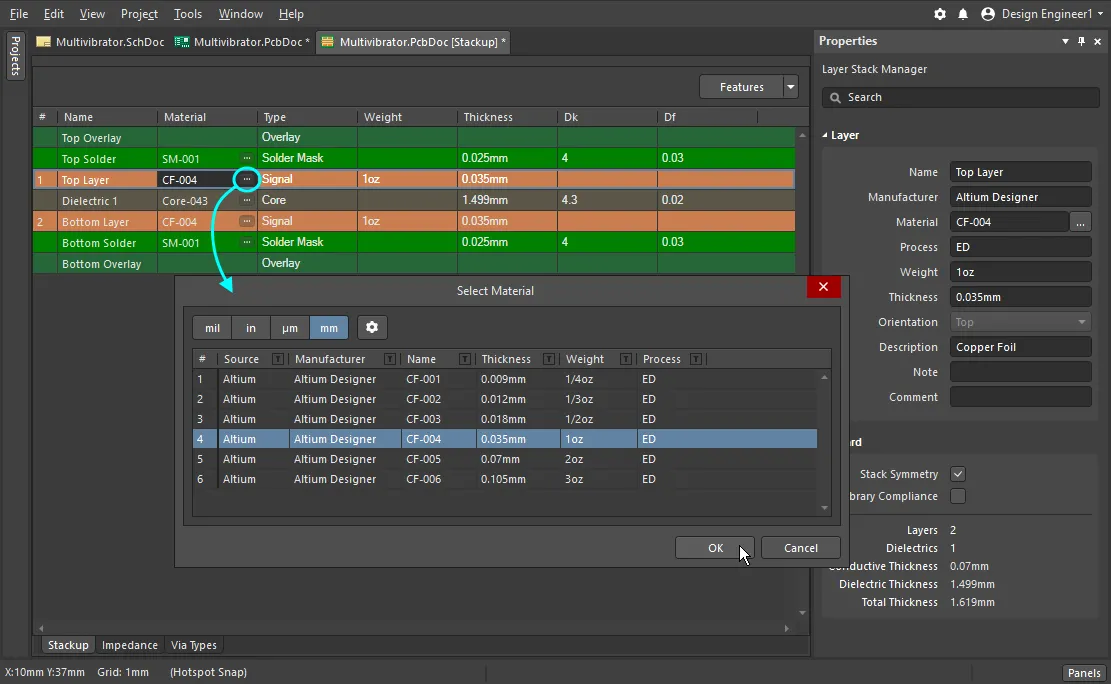

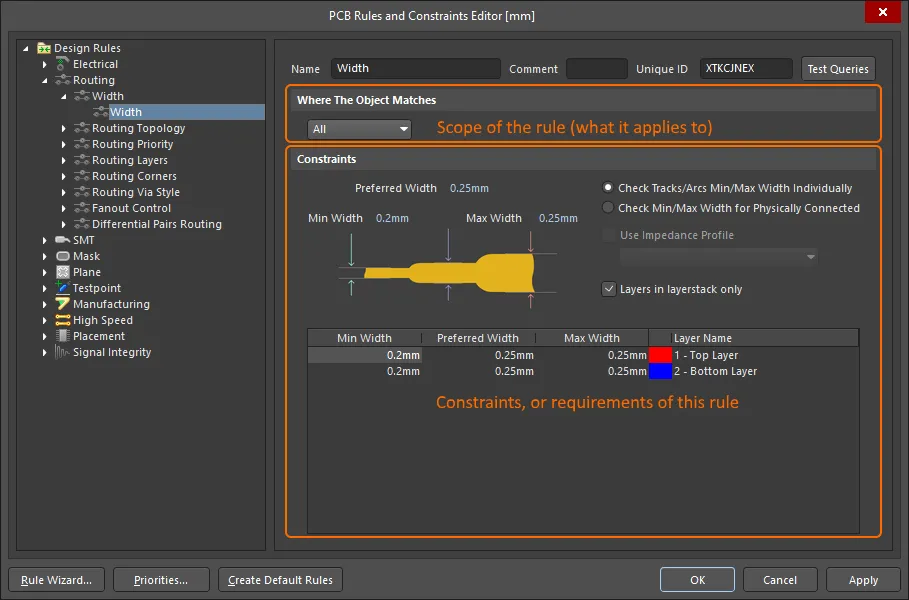

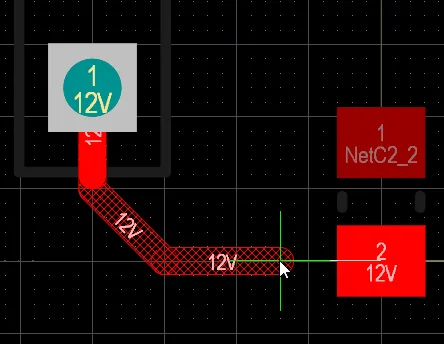

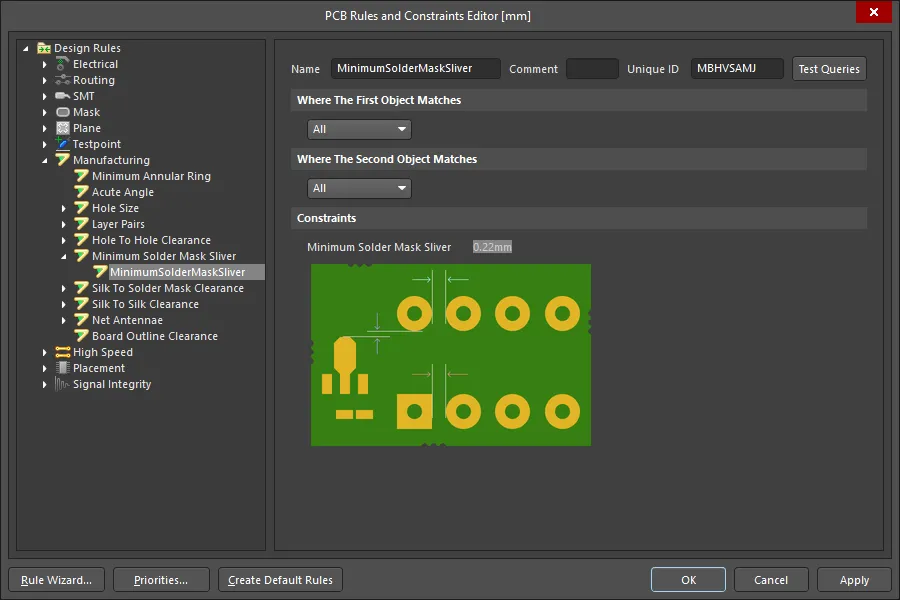

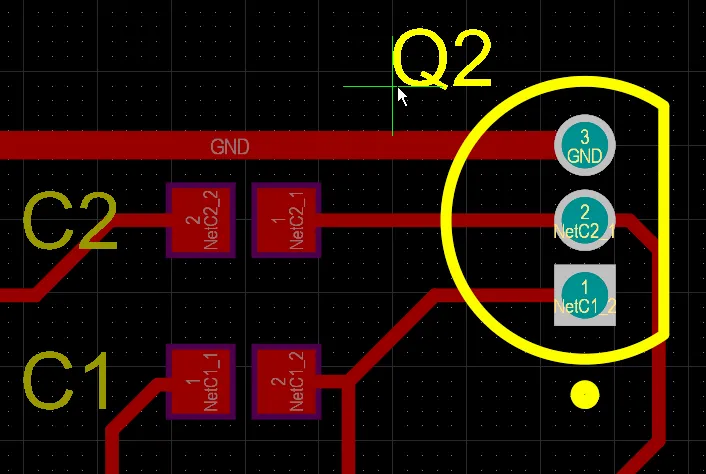

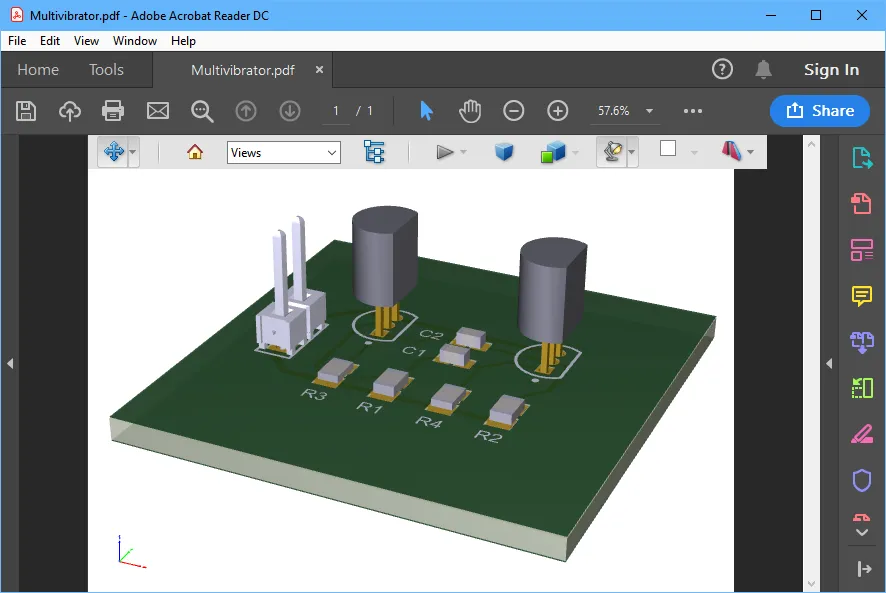

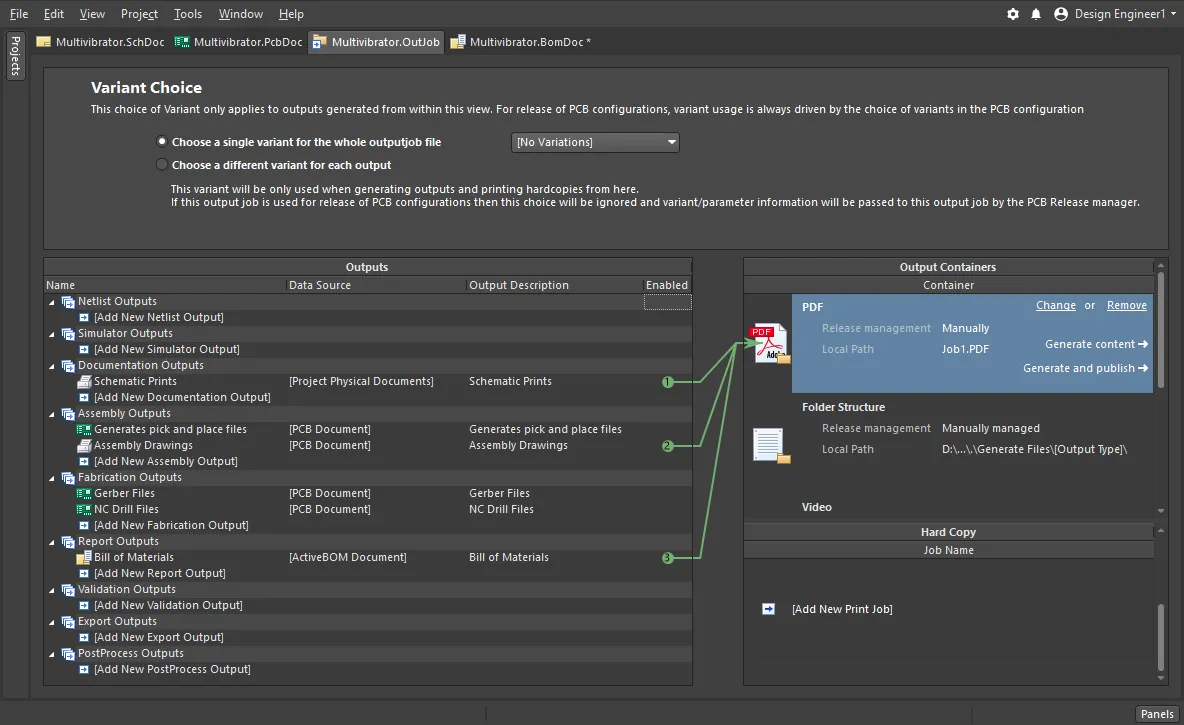

An ECO is created for each change that needs to be made to the PCB so that it matches the schematic.