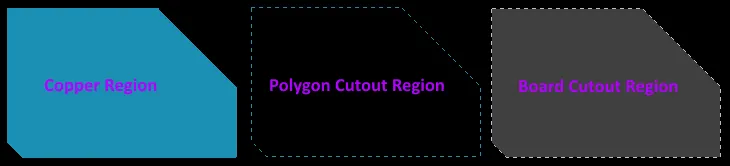

Examples of the various types of placed region objects

Summary

A Region, also known as a Solid Region, is a polygonal-shaped primitive object that can be placed on any layer.

A region can have any number of sides and vertices (corners). It can be placed on a signal layer to define an area of solid copper to be used to provide shielding or to carry large currents. Positive regions can be combined with tracks or arc segments and be connected to a net. In the PCB Library editor, regions can be used to create custom pad shapes on copper layers or special mask shapes on the solder and paste masks. On non-electrical layers, regions can be used to define custom shapes for tasks such as logos.

When placed as a negative, a region can create a cutout (a void) in a polygon pour. In this mode, the region will not be filled with copper when the polygon is poured. When used as a negative region for a board cutout (by placing it on the multi-layer), it defines an area that becomes a hole through the finished board. Board cutout regions are transferred to Gerber and ODB++ files for manufacturing purposes through the use of a dedicated Rout layer.

Availability

Regions are available for placement in both the PCB editor and the PCB Library editors in one of the following ways:

-

PCB Editor:

-

Choose Place » Solid Region, Place » Polygon Pour Cutout or Design » Board Shape » Define Board Cutout from the main menus.

-

Click the Solid Region button (

) in the drop-down on the Active Bar located at the top of the design space. (Click and hold an Active Bar button to access other related commands. Once a command has been used, it will become the topmost item on that section of the Active Bar.)

) in the drop-down on the Active Bar located at the top of the design space. (Click and hold an Active Bar button to access other related commands. Once a command has been used, it will become the topmost item on that section of the Active Bar.)

-

Right-click in the design space then click Place » Solid Region or Polygon Pour Cutout from the context menu.

-

PCB Library Editor:

-

Choose Place » Solid Region or Polygon Pour Cutout from the main menus.

-

Click the Solid Region button (

) in the drop-down on the Active Bar located at the top of the design space. (Click and hold an Active Bar button to access other related commands. Once a command has been used, it will become the topmost item on that section of the Active Bar.)

) in the drop-down on the Active Bar located at the top of the design space. (Click and hold an Active Bar button to access other related commands. Once a command has been used, it will become the topmost item on that section of the Active Bar.)

Note that Graphic objects placed in the PCB editor and PCB Library editors will automatically be converted to Region objects.

Placement

After launching the command, the cursor will change to a crosshair and you will enter region placement mode. Placement is made by performing the following sequence of actions:

-

Position the cursor then click to anchor the starting vertex for the region.

-

Move the cursor ready to place the second vertex. The default behavior is to place two edges with each click, with a user-defined corner shape between them. Refer to the Editing Polygonal Shaped PCB Design Objects page for more details.

-

Continue to move the mouse and click to place further vertices.

-

After placing the final vertex, right-click or press Esc to close and complete placement of the region. There is no need to manually close the region as the software will automatically complete the shape by connecting the start point to the final point placed.

-

Continue placing further regions or right-click or press Esc to exit placement mode.

A region will adopt a net name if it is placed over an object that is already connected to a net.

Additional actions that can be performed during placement include:

-

Press the Tab key to pause the placement and access the Region mode of the Properties panel from where its properties can be changed on the fly. Click the design space pause button overlay (

) to resume placement.

) to resume placement.

-

Press the + and - keys on the numeric keypad to cycle forward and backward through all layers currently visible in the design.

-

Press the * key to cycle through the visible signal layers.

While attributes can be modified during placement (

Tab to bring up associated properties panel), keep in mind that these will become the default settings for further placement unless the

Permanent option on the

PCB Editor – Defaults page of the

Preferences dialog is enabled. When this option is enabled, changes made will affect only the object being placed and subsequent objects placed during the same placement session.

Creating a Region from a Set of Tracks

As well as defining areas of electrical copper on a board, solid regions are also used to define other polygonal-shaped design objects, such as a special symbol or a company logo. If an outline of the required shape has been defined in another design tool, such as AutoCAD, it can be exported as DXF and then imported into Altium Designer. That outline can then be converted into a solid region.

To convert a closed boundary made up of selected track and/or arc objects to a region, select the track segments and then select:

-

Tools » Convert » Create Polygon from Selected Primitives - to define a solid (copper) region object (a region object that has its Kind property set to Copper).

-

Tools » Convert » Create Cutout from Selected Primitives - to define a polygon pour cutout region object (a region object that has its Kind property set to Polygon Cutout).

-

Tools » Convert » Create Board Cutout from Selected Primitives - to define a board cutout region object (a region object that has its Kind property set to Board Cutout).

After launching a command, a region will be created from the closed boundary formed by the track primitives. The region's boundary follows the center line of the bounding track objects and it is not selected.

Note that:

-

When selecting the Create Polygon from Selected Primitives or Create Cutout from Selected Primitives command, the region will be created on the current (or active) layer, not the layer that the selected tracks are on. When selecting the Create Board Cutout from Selected Primitives command, the region will be created on the Multi-Layer. This means you can define the shape on a mechanical layer then create the region on a signal layer/Multi-layer, respectively.

-

The selected tracks will still exist after the region has been created and will remain selected.

For Altium Designer to be a able to perform a track to region conversion, the outline must be correctly defined. That means the outline must form a closed shape, with the ends of touching track segments correctly meeting (starting/ending in the same X, Y location).

Graphical Editing

Move Region Vertices

Regions contain two points, or "handles", with which to edit the shape of the region.

-

Full Handles - located at the corners of the region.

-

Empty Handles - located in the centers of the segments created by the Full Handles.

An existing region can be re-shaped by moving these handles, or vertices, located at each corner or at the center of each edge.

To modify the region shape, click and select a region, which will highlight the vertices for the region and change the cursor to a crosshair.

-

Click on a Full Handle to move that corner.

-

Click along an edge to move the entire edge.

-

Click on an Empty Handle to move the whole side (for track and for arc).

-

Ctrl+Click on an Empty Handle to break that edge into two edges. Ctrl only needs to be held at the beginning of movement. The Shift+Spacebar hotkeys can then be used to cycle through modes (arc, miter, and any angle).

The various methods of moving region vertices.

The various methods of moving region vertices.

Modify Region Border

In addition to vertex editing, you also can use the Modify Region Border command to easily change the shape of polygons. The command is run by right-clicking on the desired polygon then selecting Polygon Actions » Modify Polygon Border. Once the command is launched, the cursor becomes a crosshair. Each time you click, a new vertex is added. As during region placement, the Shift+Spacebar shortcuts can be used to change corner shapes.

Modifying a region border.