Parent page: Working with Views

Along with the Board Assembly View and the Board Fabrication View, Draftsman suggests a number of additional automated design views to complete your PCB drawing.

Board Section View

Copy Link

Copied

A Draftsman Board Section View provides a profile slice, or sectional, drawing taken from a nominated 'cut' point through a placed Board Assembly View. The section view generator takes the available 3D data from the current PCB to create a standalone section drawing that is aligned to the nominated cut point.

Any number of Board Section Views can be created from a Board Assembly View, and its drawing representation style, view direction and labeling are all configurable in the Properties panel.

Note that section views can only be created from Board Assembly View whose View property is set to Top or Bottom.

To begin the process of creating a Section View, use the Place » Board Sectional View command, or select the  icon from the Additional Views drop down on the Active Bar. The steps to create Section B-B shown in the following image would be:

icon from the Additional Views drop down on the Active Bar. The steps to create Section B-B shown in the following image would be:

- Position the cursor on the Assembly View, where a vertical cut line (initially

A-A) will follow the cursor movement – use the Spacebar to toggle between vertical and horizontal cut lines.

- Click to set the position of the cut line.

- Move the cursor on either side of the line to set the view direction (as indicated by the cut line arrows) and click to confirm.

- Drag and place the new Section View in the desired location.

If you create multiple Board Section Views from the same Board Assembly View, it is a good idea to give them each a unique Label.

The position, size and target point of a placed Board Section View may be graphically modified when it has been selected in the design space. The view allows for different modes of graphic editing:

- Select and drag the Board Section View graphic to change its location.

- Select and drag the Board Section View's scaling handle (node), located at the top right of its outline, to modify the view's rendered size.

- Select and drag one of the Board Section View's cutting line nodes to change the extents of the cut through the board. Use the Spacebar while dragging to change the Positioning Mode (Horizontal or Vertical). The Board Section View graphic will be re-rendered to the new 3D board data when the node is released.

Drag a selected Board Section View or its scaling/cut nodes to modify the view's graphic representation.

For even greater detail, consider creating a

Board Detail View from your Board Section View.

Board Section View Properties

Copy Link

Copied

The Board Section View mode of the Properties panel.

Scale

- Scale – use the drop-down menu to choose from a range of preset scale ratios to set the visible size of the object. This option is not available if the Use Custom Scale option is checked.

- Use Custom Scale – select this option to enter a specific scale in its associated field. The scaling of the drawing object is relative to

1, where 0.9 would represent a scale of 90%.

Title

- Title – the title name string that will be displayed (if enabled) with the Section View object – use the associated

button to toggle its visibility. Enter the title name and any desired system/custom parameters to create a meaningful name for the placed view. See the Parameters section in the panel's Document Options mode for a list of the currently available parameters.

button to toggle its visibility. Enter the title name and any desired system/custom parameters to create a meaningful name for the placed view. See the Parameters section in the panel's Document Options mode for a list of the currently available parameters.

- Location – use the drop-down menu to choose from a range of relative locations for the title. The Manual option is automatically selected if the title is manually moved (dragged and dropped to a new location).

- Font – sets the displayed font used for the view's title string.

- Use Document Font checkbox selected – the title font used is that defined by the document options. See the Document Font entry in General section of the Properties panel when in Document Options mode.

- Use Document Font not selected – use the drop down menus to choose the desired font type and size, and select the lower buttons to enable text attributes. The associated color button (

) opens the color selector where the font color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level where 0% represents full transparency.

) opens the color selector where the font color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level where 0% represents full transparency.

Style

- Cutting Line – the thickness and style of the Section View's arrowed indicator lines and label. Use the line weight drop-down menu to choose from a range of line thickness presets and the line pattern menu to choose from a range of line styles. The associated color button (

) opens the line color selector dialog as outlined above.

) opens the line color selector dialog as outlined above.

- Connector Line – the line thickness and style of the Section View's cutting line, which lies between the arrowed section indicators (and passes through the Assembly View). Use the line weight drop-down menu to choose from a range of line thickness presets and the line pattern menu to choose from a range of line styles. The associated color button (

) opens the line color selector dialog as outlined above.

) opens the line color selector dialog as outlined above.

Arrow Style

- Head Style – use the drop-down menu to choose from a range of preset section indicator styles (headers). When set as arrows, these indicate the direction of view for the section.

- Width – the width of the indicator head, such as an arrow. This setting also defines the diameter of a round head style.

- Length – the length of the indicator head, such as an arrow.

- Board Cut Fill Style – displays and sets the graphic fill pattern and color of the sectioned (cut) board. Use the associated color buttons (

) to specify colors for the fill and/or hatch pattern and select the associated

) to specify colors for the fill and/or hatch pattern and select the associated  button to access the fill pattern options.

button to access the fill pattern options.

- Pattern – the graphic pattern for the sectioned board. Select Solid fill or an ANSI pattern from the drop-down menu. Select a no-fill preset or an opacity level of

0% to set the color as transparent.

Note that the pattern and color used to fill the sectioned view of a Component on the board is defined by the

Board Assembly View Properties. Select a component in the Assembly View and set the

Hatching Pattern options under

Component Display Properties in the

Properties panel or use the panel's

button to access the

Component Display Properties dialog.

- Scale – the relative line spacing of the applied ANSI hatch pattern.

- Rotation – the angle of the ANSI hatching lines where a value of

0 is equivalent to 45°.

- Hatch Thickness – the line weight of the ANSI pattern lines.

Properties

- Label – the text string/character that will be displayed as the section cut label and within the Section View title if the

ViewLabel parameter is included.

- Rotation – the angle of rotation, relative to the source Assembly View, at which the Section View is rendered. Use the drop-down menu to choose from the sequence of 90° presets.

- Positioning Mode – the X/Y orientation of the section cut. A change in the drop-down menu section, such as from

Horizontal to Vertical, will force the Section View to be re-rendered to disable the change in 3D source data.

- Flip View Selection – when checked, the section view orientation (the direction from which it is 'viewed') is inverted. Note that the cut line direction arrows will change accordingly.

- Slice Section – when checked, the visibility of objects on behind the cut line is disabled. It removes the background objects from the Section View, creating a literal cut view through the board assembly.

- Display Mode – changes the display style of the cut indicator arrows to be positioned after (

Standard) or before (Alternative) the cut line. Use the Show Connector Line checkbox to toggle the visibility of the cut line itself.

Board Detail View

Copy Link

Copied

The Draftsman Board Detail View feature allows a defined area of a drawing to be brought out to a floating, magnified view of its detail. Board Detail Views may be added to the Board Assembly View, Board Fabrication View, Board Isometric View, Board Section View, and Drill Drawing View. The Board Detail View's magnification factor (scale), labeling and line attributes are all configurable in the Properties panel.

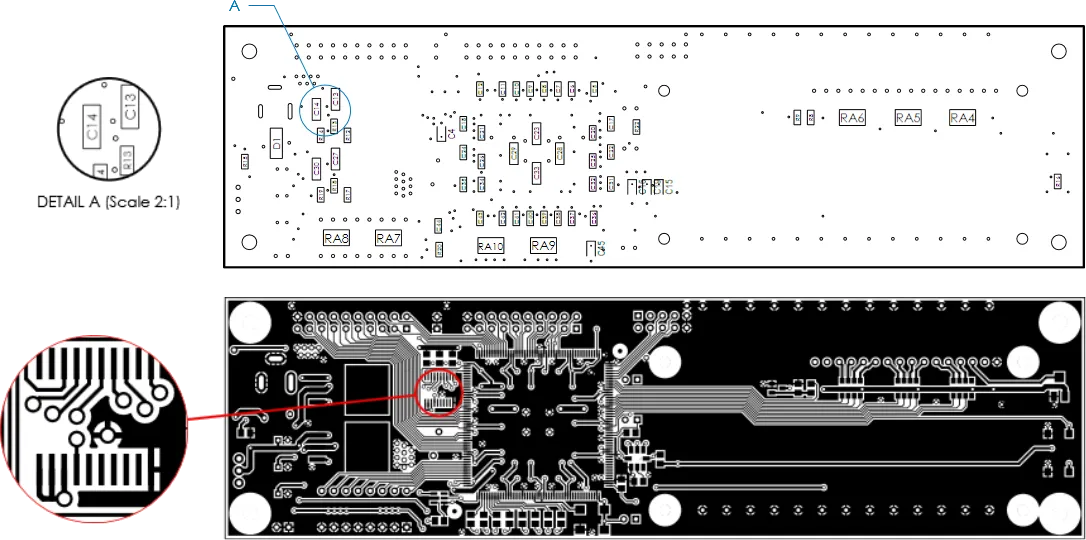

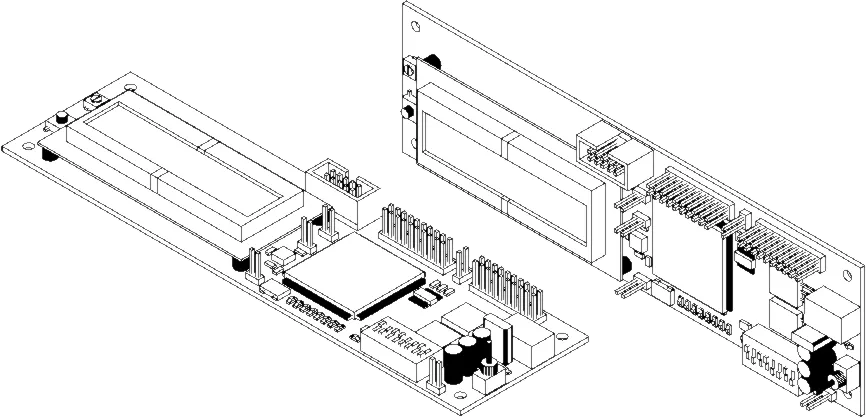

Two Board Detail Views (left) applied to a Board Assembly View and a Board Fabrication View.

The Board Detail View is placed in a drawing document by selecting the  button on the Active Bar, or via the Place menu options. When the command is launched the cursor will change to a crosshair indicating Board Detail View placement mode. The placement steps are:

button on the Active Bar, or via the Place menu options. When the command is launched the cursor will change to a crosshair indicating Board Detail View placement mode. The placement steps are:

- Click at a point on the drawing to specify the center of the target Board Detail View area.

- Move the mouse then click to specify the radius of the view area (the Board Detail View source). The Detailed View will appear floating on the cursor.

- Click again to set the position of the Board Detail View expansion.

If you create multiple Board Detail Views in your document, it is a good idea to give them each a unique Label.

Both the Board Detail View and its source area/size may be graphically modified. To enable its graphic editing mode, click on any part of the graphic representation, including the Board Detail View expansion, the source area or the connection/leader line. Once the object is selected, the cursor will change to a crosshair to indicate graphic editing mode.

Board Detail View source:

- To move the view's source area position, click within its perimeter and drag the source to a new location. Note that the cursor will change to a 'move' crosshair (

) when the cursor is hovered over the source area of a selected Board Detail View object.

) when the cursor is hovered over the source area of a selected Board Detail View object.

- To change the source area size, click on the source outline and drag to adjust its diameter. Note that the cursor will change to a 'resize' crosshair (

) when the cursor is hovered over the source area outline of a selected Board Detail View object.

) when the cursor is hovered over the source area outline of a selected Board Detail View object.

- If the Board Detail View object uses a label Leader (Display Mode set to

With Leader in the Properties panel), it will show an editing handle that may be dragged to reposition the leader and its label.

Board Detail View expansion:

- To move the Board Detail View itself (the magnified view of the source area), click and drag it to a new location.

- To move a Board Detail View title, deselect the view object (click in free space) then click and drag the title to a new location. Note that the title is part of a view object, and therefore, dragging the title of a selected object will cause the object itself to move – or in this case, the Board Detail View expansion graphic.

Board Detail View Properties

Copy Link

Copied

Component View

Copy Link

Copied

A Draftsman Component View is an Assembly View -style drawing object of a single component from the current board design. When set as a profile view, the rendered Component View object includes the related profile section of the supporting PCB. The view angle, display style and content of a Component View is configurable in the Properties panel.

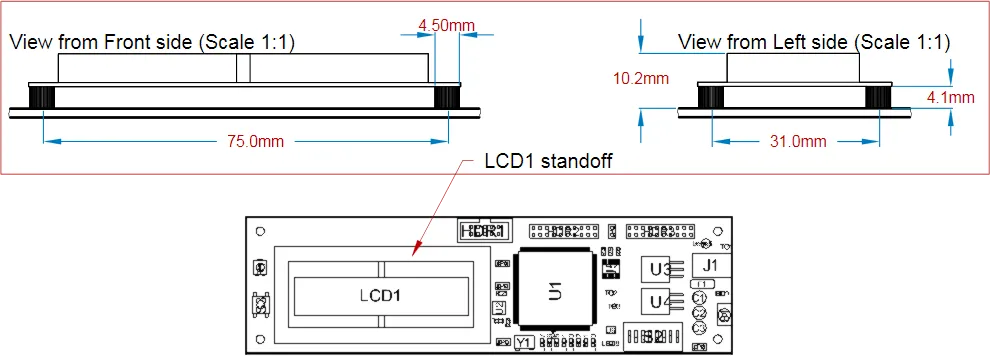

Two placed Component Views, used to illustrate mounting information for the LCD1 component shown in the lower Board Assembly View.

To place a Component View select Place » Additional Views » Component View, or choose the Component View option  from the Additional Views drop-down on the Active Bar – note that the latter option is enabled when a Board Assembly View has been placed in the document. After launching the command, drawing data is retrieved from the source PCB file, the cursor will change to a cross-hair and the rendered Component View is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

from the Additional Views drop-down on the Active Bar – note that the latter option is enabled when a Board Assembly View has been placed in the document. After launching the command, drawing data is retrieved from the source PCB file, the cursor will change to a cross-hair and the rendered Component View is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

The position of a placed Component View may be graphically changed by selecting the object in the design space then dragging it to a new location.

A placed Component View will initially show the first Component registered in the BOM data. This can be changed to the desired component from the Component menu in the Properties section of the Properties panel, which also offers the property settings that define the Component View's graphic style and view angle.

Component View Properties

Copy Link

Copied

Drill Drawing View

Copy Link

Copied

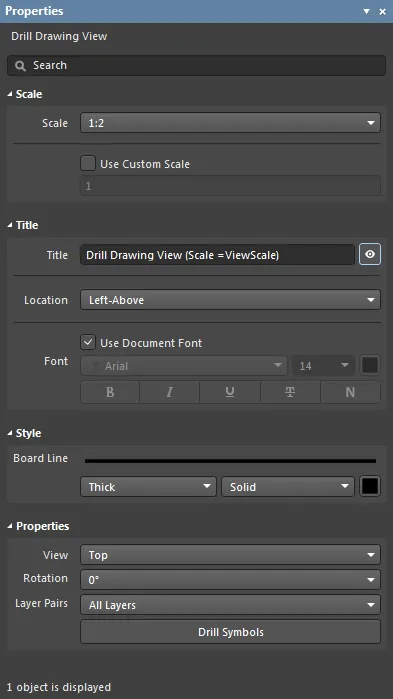

A Draftsman Drill Drawing View is an automated graphic composite of the active PCB project's board outline and drill holes. The view is rendered with definable symbols that correspond to hole types and also includes any specified drill layer pairs. The view's drawing representation and content settings are all configurable in the Properties panel.

A placed Drill Drawing can be displayed from either show holes for specific drill pairs (if available) and rendered with defined hole group symbols.

The Drill Drawing view for the selected PCB is placed in a drawing document by selecting the  button on the Active Bar, or via the Place menu options. After launching the command, drawing data is retrieved from the source PCB file, the cursor will change to a cross-hair and the rendered Drill Drawing View is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

button on the Active Bar, or via the Place menu options. After launching the command, drawing data is retrieved from the source PCB file, the cursor will change to a cross-hair and the rendered Drill Drawing View is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

Note that drawing data is retrieved from the PCB document specified in the Source section of the Properties panel when in Document Options mode. To change the panel to that mode, deselect all objects in the design space (click in free space).

Both the position and size of placed Drill Drawing View may be graphically modified.

A selected Drill Drawing View will show a node handle at the top right of the selection outline, which can be dragged to a new location to modify the view's size. To move a Drill Drawing View, drag and drop it to a new location.

Drag a selected Drill Drawing View's resize node change its scale.

By default, the view is from the top side of the board, and for all layers. This can be changed after placement as required, through the Properties panel. Alternatively, copy and paste the initial view as many times as you need, with each copy changed to show a different perpective and layer pairing.

Assigned drill symbol graphics for the various drill holes can be changed in the Drill Symbol Configurations dialog. Access to this dialog is made by clicking the Drill Symbols button, at the bottom of the Properties section of the Properties panel, when browsing/modifying the properties of the selected Drill Drawing View. The dialog presents a tabular view of PCB hole data, with hole styles grouped on a selectable parameter (column data) basis and assigned standard symbols.

For even greater detail, consider creating a

Board Detail View from your Drill Drawing View.

Drill Drawing View Properties

Copy Link

Copied

The Drill Drawing View mode of the Properties panel.

Scale

- Scale – use the drop-down to choose from a range of preset size scale ratios. This option is not available if the Use Custom Scale option is checked.

- Use Custom Scale – select this option to enter a specific scale in its associated field. The scaling of the drawing object is relative to

1, where 0.9 would represent a scale of 90%.

Title

- Title – the title name string that will be displayed (if enabled) with the Drill Drawing View object. Use

or

or  to determine whether the string is displayed or hidden (respectively) in the design space. Enter the title name and any desired system/custom parameters to create a meaningful name for the placed view. See the Parameters section in the Properties panel's Document Options mode for a list of the currently available parameters.

to determine whether the string is displayed or hidden (respectively) in the design space. Enter the title name and any desired system/custom parameters to create a meaningful name for the placed view. See the Parameters section in the Properties panel's Document Options mode for a list of the currently available parameters.

- Location – use the drop-down to choose from a range of relative locations for the title. The Manual option is automatically selected if the title is manually moved (dragged and dropped to a new location).

- Font – sets the displayed font used for the view's title string.

- Use Document Font checkbox selected – the title font used is that defined by the document options. See the Document Font entry in the General section of the Properties panel when in Document Options mode.

- Use Document Font not selected – use the drop-down menus to choose the desired font type and size and select the lower buttons to enable text attributes. The associated color button (

) opens the color selector where the font color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level where 0% represents full transparency.

) opens the color selector where the font color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level where 0% represents full transparency.

Style

- Board Line – the thickness and style of the Drill Drawing View's border/outline. Use the drop-down menus to choose from a range of line thickness presets and the line pattern menu to choose from a range of line styles. The associated color button (

) opens the line color selector dialog as outlined above.

) opens the line color selector dialog as outlined above.

Properties

- View – the direction of view used to render the board drawing. Use the drop-down menu to specify the Top or Bottom view direction.

- Rotation – the rotation angle at which the Drill Drawing is rendered as selected from the sequence of 90° preset options is in the drop-down menu.

-

Layer Pairs – select which PCB drill Layer Pair holes will be displayed in the drawing view. Use the drop-down menu to choose from the Layer Pairs that are available in the source board design as can be viewed and edited in the PCB Editor's Layer Stack Manager. All board designs will have a Top Layer to Bottom Layer pair, while other pairs will represent via holes passing between or to other layers, such as internal/plane layers.

The

Counterhole Bottom and

Counterhole Top options are available only when the PCB document includes

Pad objects with Counterhole features enabled on corresponding sides of the PCB.

Note that counterholes are excluded from layer pairs other than Counterhole Bottom and Counterhole Top, including All Layers.

- Drill Symbols – select to open the Drill Symbol Configurations dialog, which provides a tabular view of all drill hole data and allows the setting of the style and size for each hole symbol.

Board Isometric View

Copy Link

Copied

A Draftsman Board Isometric View is an automated projection graphic composite of the active PCB project's board assembly. Its drawing projection representation and graphic style elements are configurable in the Properties panel.

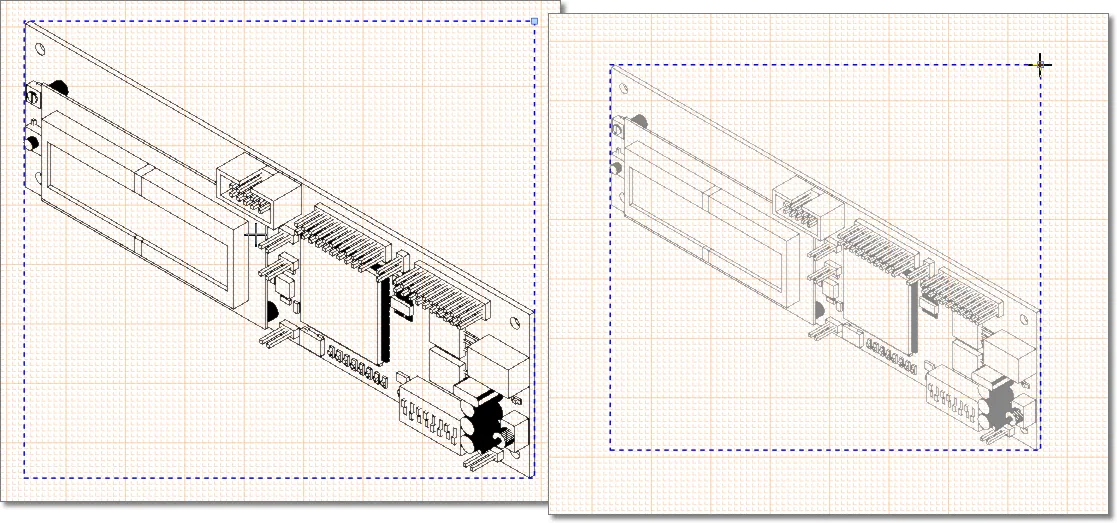

Two placed Board Isometric Views; a front face isometric view on the left, and a top face isometric view on the right. Set the face side view in the Properties panel.

The Board Isometric View is placed in a drawing document by selecting the Place » Board Isometric View command. After launching the command, drawing data is retrieved from the source PCB file, the cursor will change to a cross-hair and the rendered Board Isometric View is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

Note that drawing data is retrieved from the PCB document specified in the Source section of the Properties panel when in Document Options mode. To change the panel to that mode, deselect all objects in the design space (click in free space).

Both the position and size of placed Board Isometric View may be graphically modified.

A selected Board Isometric View will show a node handle at the top right of the selection outline, which can be dragged to a new location to modify the view's size. To move a Board Isometric View, drag and drop it to a new location.

Drag a selected Board Isometric View to change its position. Drag its resize node change the drawing scale.

The properties and option settings for a placed Isometric View are available in the Properties panel when a placed Isometric View is selected in the design space. In the panel's Properties section, use the Face Side drop-down menu to select the projection view perspective, and the Variants menu to specify which project design variation (if available) is shown.

Board Isometric View Properties

Copy Link

Copied

Board Region View

Copy Link

Copied

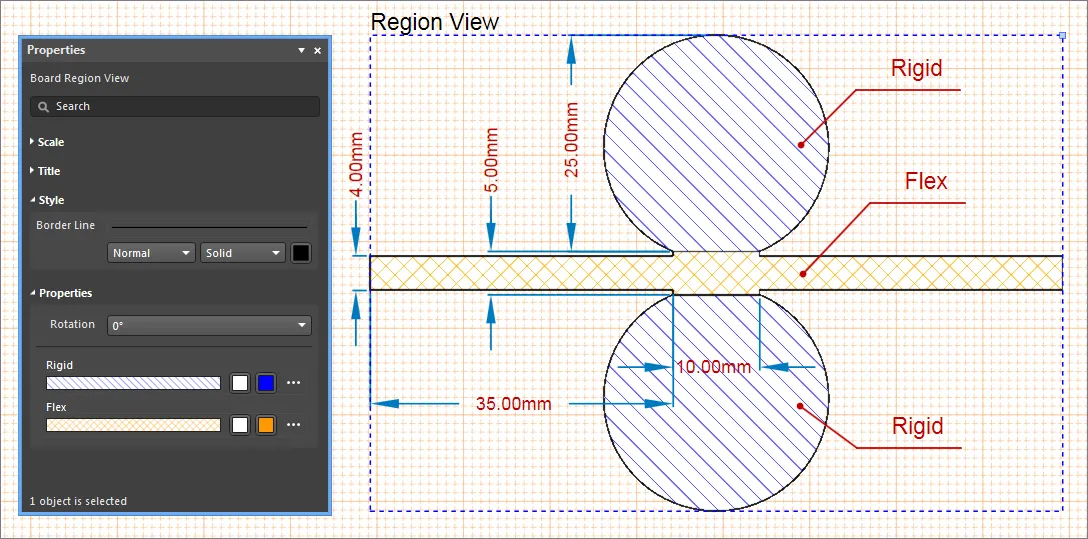

The Board Region View allows a Draftsman document to include an accurate representation of multiple Layer Stack regions in a board design, such as those applied in Rigid-Flex PCB designs. Its graphic style elements are configurable in the Properties panel.

A placed Board Region View with attached Callout objects, which automatically identify the board's Layer Stack Regions.

The Region View is available for placement from the Place » Additional Views » Board Region View command on the main menu, or from the additional views drop-down menu on the Active Bar. After launching the command, Layer Stack region drawing data is retrieved from the source PCB file, the cursor will change to a cross-hair and the rendered Board Region View is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

Layer Stack naming and data applied in the Board Region View is drawn from the PCB design, as represented in the PCB editor’s Board Planning Mode view and Layer Stack Manager.

Note that drawing data is retrieved from the PCB document specified in the

Source section of the

Properties panel when in

Document Options mode. To change the panel to that mode, deselect all objects in the design space (click in free space).

Both the position and size of placed Board Region View may be graphically modified.

- A selected Board Region View will show a node handle at the top right of the selection outline, which can be dragged to modify the view's size.

- To move a Board Region View, click within the selection then drag and drop it to a new location.

- As a Board Region View is being dragged, press the Spacebar to rotate the object in 90° increments.

Drag a selected Board Region View to change its position. Drag its resize node to change the drawing scale.

A Callout placed in the Region View will automatically identify a board Layer Stack region, and dimensions may be added to the view to provide details of the stack region areas and divisions.

Board Region View Properties

Copy Link

Copied

Board Realistic View

Copy Link

Copied

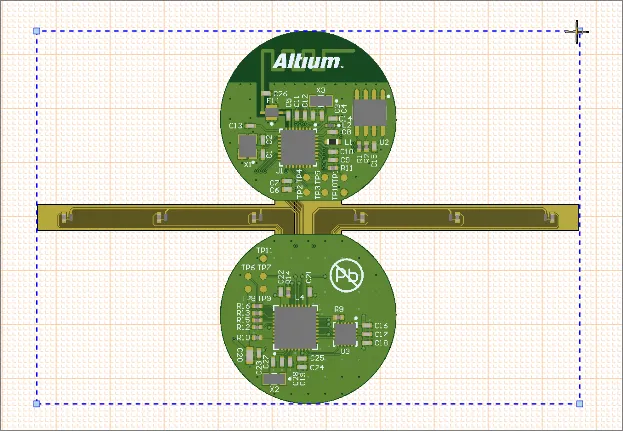

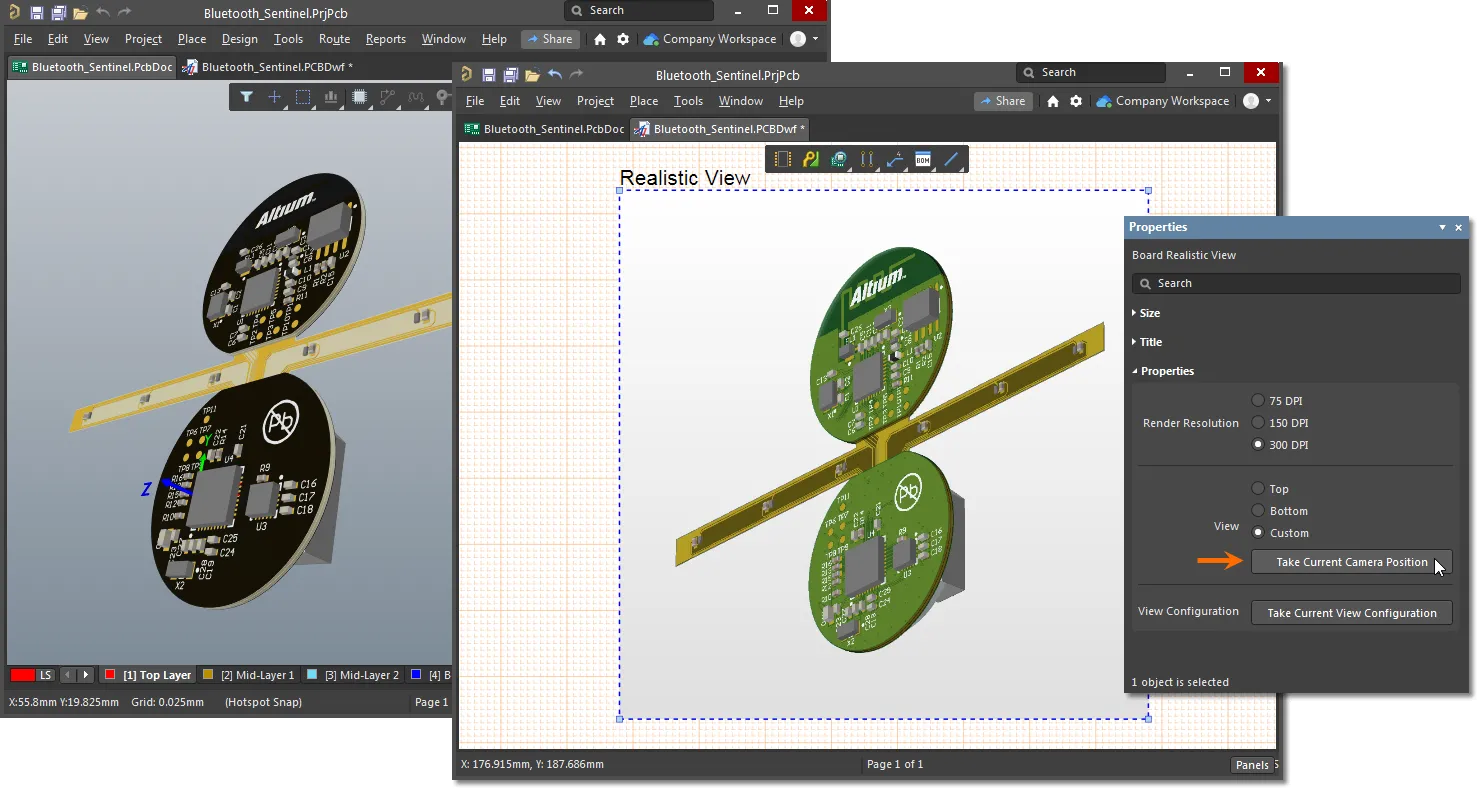

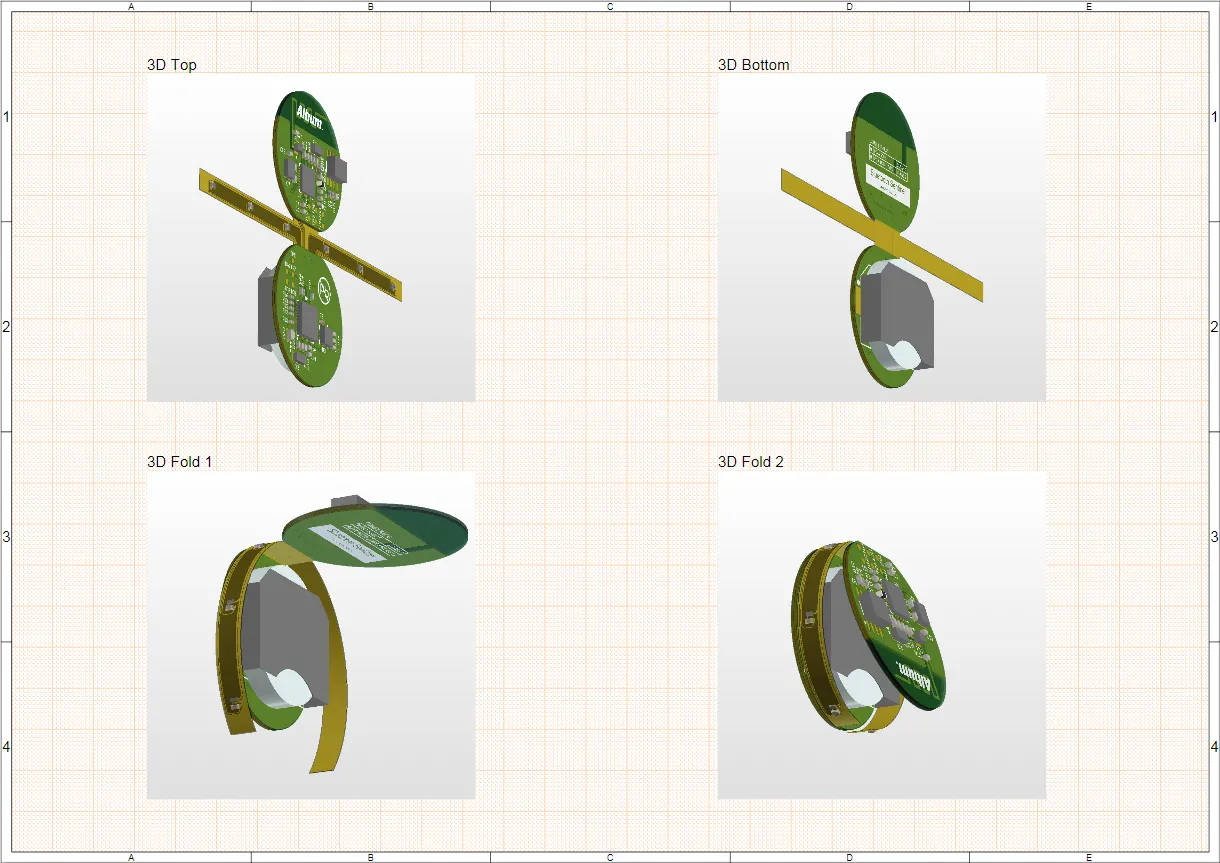

A Draftsman Board Realistic View provides a high level of purely visual information to Assembly and Fabrication data in a drawing document. Placed as a separate and configurable view object, the Realistic View provides a scalable 3D rendering of the current board design. The 3D view is generated by the software’s 3D rendering engine – as applied in the PCB Editor and for 3D print outputs – and may be set to adopt the PCB Editor’s current view angle and configuration. Its graphic style elements are configurable in the Properties panel.

A placed Board Realistic View where the view angle has been taken from the PCB editor using the Camera Position option.

A placed Board Realistic View where the view angle has been taken from the PCB editor using the Camera Position option.

The Realistic View is available for placement from the Place » Additional Views » Board Realistic View command on the main menu, or from the additional views drop-down menu on the Active Bar. After launching the command, 3D drawing data is generated and retrieved from the source PCB file, the cursor will change to a cross-hair and the rendered Board Realistic View is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

Note that 3D drawing data is retrieved from the PCB document specified in the

Source section of the

Properties panel when in

Document Options mode. To change the panel to that mode, deselect all objects in the design space (click in free space).

Both the position and size of placed Board Realistic View may be graphically modified.

- A selected Board Realistic View will show editing node handles at each corner of the selection outline, which can be dragged to modify the view's size. The view's dimensions will remain proportional while being resized unless the Maintain Aspect Ratio option is unchecked in the Properties panel.

- To move a Board Realistic View, click within the selection then drag and drop it to a new location.

- As a Board Realistic View is being dragged, press the Spacebar to rotate the object in 90° increments.

Drag a selected Board Realistic View to change its position. Drag its resize nodes to change the drawing scale.

Use the Properties panel options to set the visual properties of a placed and selected view. The Properties section of the panel includes a Custom view setting that allows the view display properties to be set from the current PCB Editor 3D view.

Use the  button for the view to adopt the PCB Editor’s current 3D view.

button for the view to adopt the PCB Editor’s current 3D view.

Use the  button to adopt the view settings that are currently applied in the PCB Editor 3D view – as defined in the editor’s View Configuration panel (set to Layer colors in the below example).

button to adopt the view settings that are currently applied in the PCB Editor 3D view – as defined in the editor’s View Configuration panel (set to Layer colors in the below example).

Since a Board Realistic View is able to adopt the current settings of the PCB Editor 3D view, multiple Realistic View objects can be placed in a Draftsman document where each takes a different configuration/view 'snapshot' from the PCB Editor's 3D view.

Board Realistic View Properties

Copy Link

Copied

Counter Hole View

Copy Link

Copied

A Draftsman document's Counter Hole View provides a representation of a board's pad hole with counter hole features (counterbore and/or countersink). When set as a profile view, the rendered Counter Hole View object includes the related profile section of the PCB. The view angle, display style and content of a Counter Hole View is configurable in the Properties panel.

Two placed Counter Hole Views, set to Top and Left View Sides respectively.

To place a Counter Hole View, select Place » Additional Views » Counter Hole View, or choose the Counter Hole View option  from the Additional View drop-down on the Active Bar. After launching the command, drawing data is retrieved from the source PCB file, the cursor will change to a cross-hair and the rendered Counter Hole View is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

from the Additional View drop-down on the Active Bar. After launching the command, drawing data is retrieved from the source PCB file, the cursor will change to a cross-hair and the rendered Counter Hole View is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

The position of a placed Counter Hole View may be graphically changed by selecting the object in the design space then dragging it to a new location.

When dragging a Counter Hole View with the Left ViewSide selected in its properties, use the Spacebar to rotate the view through 90° increments.

A placed Counter Hole View will initially show the hole of one of the PCB pads with a counter hole feature applied. This can be changed to the desired pad from the Counter Hole menu in the Properties section of the Properties panel, which also offers the property settings that define the Counter Hole View's graphic style and view angle.

Counter Hole View Properties

Copy Link

Copied

Via Type View

Copy Link

Copied

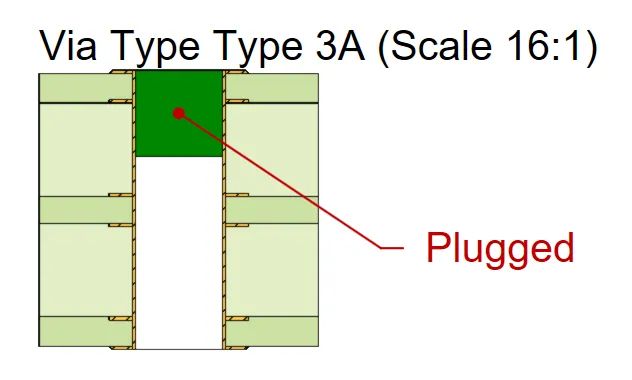

A Draftsman document's Via Type View provides a representation of a via type according to the IPC-4761 standard, Design Guide for Protection of Printed Board Via Structures. The display style and content of a Via Type View is configurable in the Properties panel.

A placed Via Type View used to illustrate a Type 3A via (sealing with a non-conductive material on one side, which partially enters the via).

To place a Via Type View, select Place » Additional Views » Via Type View, or choose the Via Type View option  from the Additional View drop-down on the Active Bar. After launching the command, the cursor will change to a cross-hair and the rendered Via Type View is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

from the Additional View drop-down on the Active Bar. After launching the command, the cursor will change to a cross-hair and the rendered Via Type View is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

Both the position and size of placed Via Type View may be graphically modified.

- A selected Via Type View will show a node handle at the top right of the selection outline, which can be dragged to modify the view's size.

- To move a Via Type View, click within the selection then drag and drop it to a new location.

- As a Via Type View is being dragged, press the Spacebar to rotate the object in 90° increments.

A placed Via Type View will initially show a Type 1A via. This can be changed to the desired via type from the ViaType menu in the Properties section of the Properties panel, which also offers the property settings that define the Via Type View's graphic style.

A Callout placed on the Via Type View will automatically identify the associated via structure.

Via Type View Properties

Copy Link

Copied

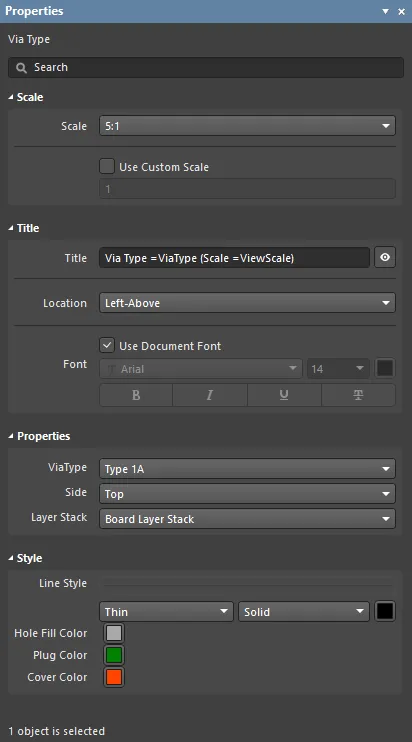

The Via Type mode of the Properties panel

Scale

- Scale – use the drop-down to choose from a range of preset scale ratios (magnification). This option is not available if the Use Custom Scale option is checked.

- Use Custom Scale – select this option to enter a specific scale in its associated field. The scaling of the drawing object is relative to

1, where 0.9 would represent a scale of 90%.

Title

- Title – the title name string that will be displayed (if enabled) with the Via View object. Use the associated

button to toggle its visibility. Enter the title name and any desired system/custom parameters to create a meaningful name for the placed view. See the Parameters section in the Properties panel's Document Options mode for a list of the currently available parameters.

button to toggle its visibility. Enter the title name and any desired system/custom parameters to create a meaningful name for the placed view. See the Parameters section in the Properties panel's Document Options mode for a list of the currently available parameters.

- Location – use the drop-down to choose from a range of relative locations for the title. The Manual option is automatically selected if the title is manually moved (dragged and dropped to a new location).

- Font – sets the displayed font used for the view's title string.

- Use Document Font checkbox selected – the title font used is that defined by the document options. See the Document Font entry in the General section of the Properties panel when in Document Options mode.

- Use Document Font not selected – use the drop-down menus to choose the desired font type and size and select the lower buttons to enable text attributes. Note that the slider control sets the color Opacity level where 0% represents full transparency.

Properties

- ViaType – the via type according to the IPC-4761 standard used to render the via drawing. Use the drop-down menu to select from a range of preset via types.

- Side - use the drop-down to select from what side covering should be applied. For via types 1A, 2A, 3A, 4A, and 6A, choose from either Top or Bottom. For via types 1B, 2B, 3B, 4B, 5, 6b, and 7, the option is essentially disabled with Both as the only option and is the default for those via types.

- Layer Stack – the PCB design layer stack, as defined in the PCB editor's Layer Stack Manager, according to which the Via Type View will be rendered. Use the drop-down menu to select from the list of all available layer stacks.

Style

- Line Style – the thickness and style of the Via Type View lines. Use the drop-down menus to choose from a range of line thickness presets and the line style. The associated color button (

) opens the line color selector dialog as outlined for Font above.

) opens the line color selector dialog as outlined for Font above.

- Hole Fill Color – the color used to render the hole fill in the Via Type View. The associated color button (

) opens the color selector dialog as outlined above.

) opens the color selector dialog as outlined above.

- Plug Color – the color used to render the plug in the Via Type View. The associated color button (

) opens the color selector dialog as outlined above.

) opens the color selector dialog as outlined above.

- Cover Color – the color used to render the cover in the Via Type View. The associated color button (

) opens the color selector dialog as outlined above.

) opens the color selector dialog as outlined above.

Layer Stack Legend

Copy Link

Copied

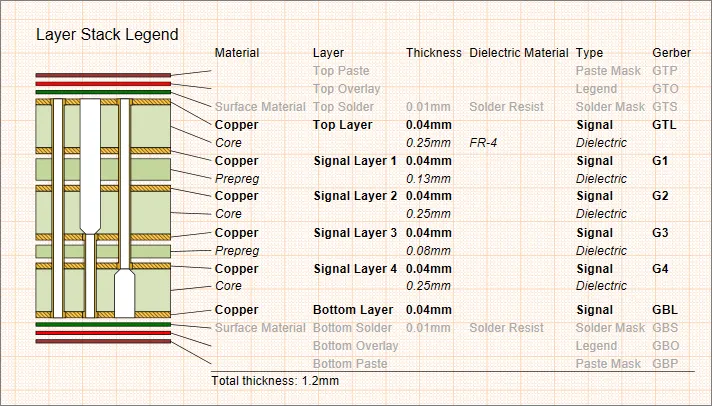

A Draftsman document's Layer Stack Legend view provides a representation of the board's internal structure as an enlarged sectional view. It includes detailed descriptions and information for each layer in the stack, including the Gerber files associated with each layer. The Layer Stackup Legend's visual style and included information are all configurable in the Properties panel.

A placed Layer Stack Legend derives data from the Layer Stack for the nominated PCB and can be displayed with relative layer thickness and drill pairs.

To place a Layer Stack Legend view in a drawing document, use the Place » Layer Stack Legend command or select the  Icon from the Additional Views drop down on the Active Bar. After launching the placement command, board layer stack data is retrieved from the source PCB file, the cursor will change to a cross-hair and the generated Layer Stack Legend is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

Icon from the Additional Views drop down on the Active Bar. After launching the placement command, board layer stack data is retrieved from the source PCB file, the cursor will change to a cross-hair and the generated Layer Stack Legend is attached to the cursor. Move the cursor to the desired position then click to confirm the placement.

Note that layer stack data is retrieved from the PCB document specified in the

Source section of the

Properties panel when in Document Options mode. To change the panel to that mode, deselect all objects in the design space (click in free space).

The position of a placed Layer Stack Legend may be graphically changed by selecting the table in the design space then dragging it to a new location. Note that the Layer Stack object cannot be graphically resized, but will automatically scale to accommodate the font style/size and stack graphic dimensions as specified in the Properties panel.

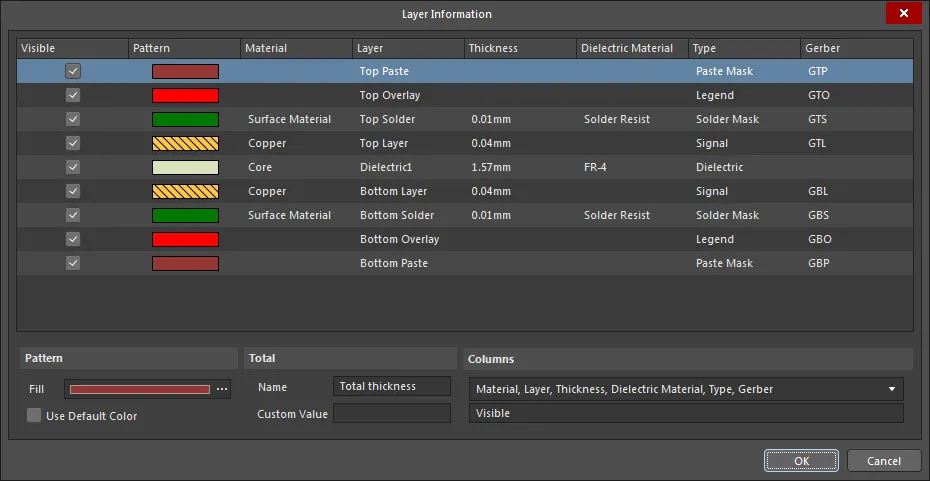

By default, the information for each layer is derived from the corresponding attributes in the Board Layer Stack, as defined in the PCB editor's Layer Stack Manager, however, the layer description attributes may be edited and expanded in Draftsman through the Properties panel and the Layer Information dialog, accessed by clicking the Layer Info button in the Properties panel (under the Properties region of the panel).

The Layer Information dialog

Options and Controls of the Layer Information Dialog

Copy Link

Copied

Note that the Layer Stack display and information options define the structure and content of the Layer Stack Legend that has been placed into a drawing document, and do not affect the Board Layer Stack configuration that is defined in the source PCB document.

Once a cell of a Layer Stack Legend has been manually edited in the legend, it will not be updated from the board data when using the Import Changes From <BoardFileName>.PcbDoc command.

Including the Physical Layer Number

The Layer Stack Legend can include the physical layer number, if required. This value is the layer number assigned to that copper layer in the PCB editor's Layer Stack Manager.

To include the physical layer number in the Draftsman Layer Stack Legend: select the Legend; click the Layer Info button in the Properties panel to open the Layer Information dialog; then enable the # (hashtag) in the Columns drop-down. You might need to refresh the PCB data before the additional column is displayed, right-click anywhere on the Draftsman drawing and select Import Changes From <BoardFileName>.PCBDoc to refresh.

The Layer Stack Legend can include the physical layer number if required.

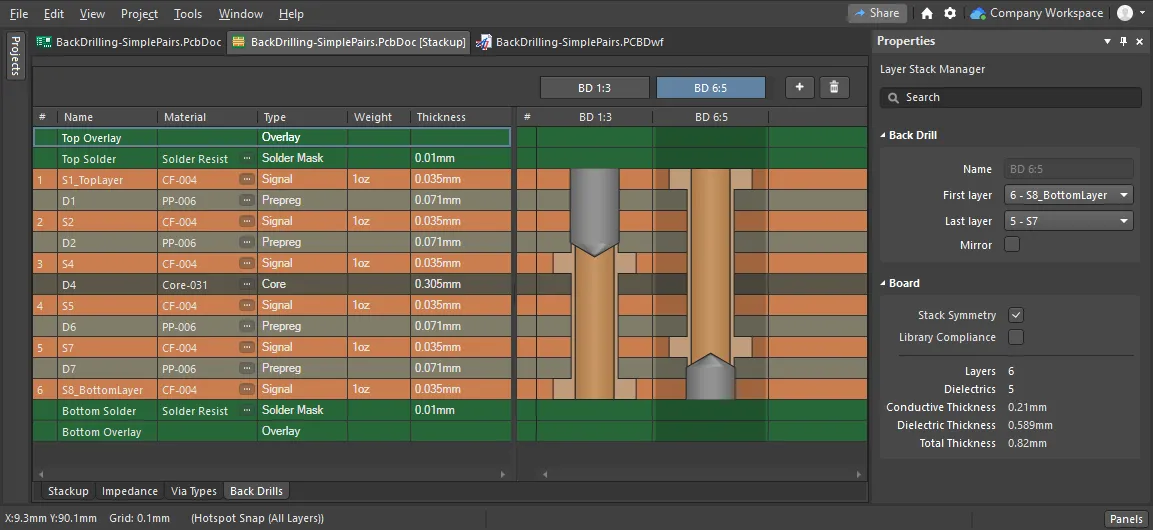

Back Drilling compatibility

Controlled Depth Drilling (Backdrilling) in Altium Designer is a methodology for detecting and removing electrically redundant sections of plated through holes.

These are typically found where a standard through-hole Via connects the signal to an inner layer, leaving the remaining portion of the Via barrel as an undesired ‘stub’ – in turn, this stub is likely to compromise the performance of a high-speed design. In the backdrilling technique, the stubs are removed by drilling to a precise (Z) depth with a slightly oversized drill.

Altium Designer uses a specific Design Rule and assigned Back Drill Pairs to automatically create the correct NC Drill output files. In a Draftsman document, this arrangement is represented in the Layer Stack Legend, which includes a graphical representation of all Drill Pairs defined for the board, including any Back Drill Pairs (shown with partially drilled out Via barrels).

The Layer Stack Legend view showing backdrilling enabled between the Top and Signal 3 layers, and the Signal 4 and Bottom layers.

Note that the Back Drills are defined in the Back Drills tab of the PCB editor's Layer Stack Manager.

Back Drills are defined in the PCB editor's Layer Stack Manager.

Layer Stack Legend Properties

Copy Link

Copied

The Layer Stack Legend mode of the Properties panel

Title

- Title – the title name string that will be displayed (if enabled) with the Layer Stack Legend object. Use the associated

button to toggle its visibility. Enter the title name and any desired system/custom parameters to create a meaningful name for the placed object. See the Parameters section in the Properties panel's Document Options mode for a list of the currently available parameters.

button to toggle its visibility. Enter the title name and any desired system/custom parameters to create a meaningful name for the placed object. See the Parameters section in the Properties panel's Document Options mode for a list of the currently available parameters.

- Location – select the drop-down to choose from a range of relative locations for the title. The Manual option is automatically selected if the title is manually moved (dragged and dropped to a new location).

- Font – sets the displayed font used for the view's title string.

- Use Document Font checkbox selected – the title font used is that defined by the document options. See the Document Font entry in the General section of the Properties panel when in Document Options mode.

- Use Document Font not selected – use the drop-down menus to choose the desired font type and size and select the lower buttons to enable text attributes. The associated color button (

) opens the color selector, where the font color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level, where 0% represents full transparency.

) opens the color selector, where the font color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level, where 0% represents full transparency.

Style

- Line – the thickness and style of the line between each layer representation and its corresponding specification table row. Use the line weight drop-down menu to choose from a range of line thickness presets, and the line pattern menu to choose from a range of line styles. The associated color button (

) opens the color selector where the line color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level, where 0% represents full transparency.

) opens the color selector where the line color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level, where 0% represents full transparency.

- View Line – the line thickness and style of the layer representation outlines. Use the line weight drop-down menu to choose from a range of line thickness presets, and the line pattern menu to choose from a range of line styles. The associated color button (

) opens the color selector where the view line color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level, where 0% represents full transparency.

) opens the color selector where the view line color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level, where 0% represents full transparency.

- Justification - select the desired justification by clicking on an arrow that corresponds with the desired justification or the circle to center.

Properties

- Display Mode – determines the rendered height of each layer representation in the Layer Stack graphic within the constraints of the Min/Max Layer Height settings (see below). Use the drop-down to choose the layer heights option:

Default – all layers are rendered at the same standard height.- Real Width in Heights – layers are rendered at a height that is proportional to the actual thickness of each board layer.

- Align Table Rows – layers are rendered at a height that aligns to the table row contents.

- Width – sets the rendered width of the Layer Stack graphic. The minimum width is determined by the number of drill Layer Pairs included.

- Source – sets the board data source used to create the Layer Stack object. This is the

Board Layer Stack for conventional board designs or the choice of Rigid or Flex layer stacks for advanced Rigid-Flex designs.

- Show Drill Pairs – enables a graphic representation of the Drill Layer Pairs assigned to the board design, as defined by the PCB project's Defining the Layer Stack. Note that any Drill Pairs with Back Drilling enabled include a representation of the oversize back drill hole.

- Min Layer Height – the minimum rendered height of any layer. This setting will only influence the graphic when the Layer Heights option is set to Real Width in Heights.

- Max Layer Height – the maximum rendered height of any layer. This setting will only influence the graphic when the Layer Heights option is set to Real Width in Heights.

- Gap Between Layers - sets the amount of free space desired between layer rows in the Layer Stack Legend table.

- Show Header – enable/disable the column header captions in the Layer Stack Legend table.

- Show Footer – enable/disable the total board thickness readout at the bottom of the table.

- Font – sets the Header and Footer font used in the Layer Stack Legend table.

- Use Document Font checkbox selected – the font used is that defined by the document options. See the Document Font entry in General section of the Properties panel when in Document Options mode.

- Use Document Font not selected – use the drop-down menus to choose the desired font type and size, and select the lower buttons to enable text attributes. The associated color button (

) opens the color selector, as outlined in the Title section above.

) opens the color selector, as outlined in the Title section above.

- Usual Layer Font – sets the font used for the table information that relates to the board's outer/surface layers, such as the Paste, Silkscreen and Solder layers. Use the drop-down menus to choose the desired font type and size, and select the lower buttons to enable text attributes. The associated color button (

) opens the color selector where the font color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level, where 0% represents full transparency.

) opens the color selector where the font color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level, where 0% represents full transparency.

- Signal Layer Font – sets the font used for the table information that relates to the board's copper signal carrying layers, such as the Top/Bottom and internal/plane layers. Use the drop-down menus, text attributes and color selector as described above.

- Dielectric Font – sets the font used for the table information that relates to the board's dielectric core layers. Use the drop-down menus, text attributes and color selector where the font color can be specified by RGB or HEX value, by freeform selection, or from a range of presets. Note that the slider control sets the color Opacity level, where 0% represents full transparency.

- Relation Width – sets the distance between the layers graphic and the table, and by association the length of the layer to table row indicator lines.

- Layer Info – opens the Layer Information dialog, which allows the editing of the Layer Stack Legend's table data and graphics color/visibility. Note that the initial data values are sourced from the project board design.

Units

- Primary Units – select the main dimension unit type that will be shown in the table. Use the associated

button to toggle the unit's visibility.

button to toggle the unit's visibility.

- Dual Units – set the secondary dimension unit type that will be shown in the table. Use the associated

button to toggle the unit's visibility.

button to toggle the unit's visibility.

Precision

Specifies the numerical precision (number of significant digits to the right of the decimal point, with the last digit rounded) for the layer specifications.

- Primary Units – use the Value Precision drop-down menu to choose the numerical rounding for the Primary (main) layer dimension table entries.

- Dual Units – use the Value Precision drop-down menu to choose the numerical rounding for the Dual (secondary) layer dimension table entries, if enabled.