Tools for Electrical Engineers to

Collaborate More Effectively

Electrical engineers face productivity challenges every day. Design data and feedback are scattered across drives, emails, drawings, and direct messages. ECAD software lacks the high-quality supply chain data designers need to find affordable approved parts. Not to mention their struggles with disorganized component libraries. Altium 365 collaboration tools for electrical engineers solve these challenges, simplifying and streamlining electronic product development.

Standardize Your Component Library

The library is one of an electrical engineer’s most valuable assets. Ensure its integrity and manage your components in one central and secure location. Everyone working on a board design can use the same set of validated components. Templates standardize component creation, ensuring all the required parameters are populated. With defined lifecycles, your team always knows which components can be used in a design and which are obsolete.

Efficient Design Collaboration

Share the real-time state of projects with team members and manufacturers, allowing them to review and mark up designs without leaving your design space. Remove silos and inefficiencies in the hardware development process with electronic design automation and powerful collaboration tools. Transparent design reviews and simple data sharing empower electronic design companies to bring products to market faster than their competitors.

Access Supply Chain Data in Your ECAD Software

Bridge the gap between engineering and procurement with up-to-date supply chain data embedded into your design flow. Enable engineers and procurement teams to make informed decisions during part research, with details on availability, compliance information, risks, and costs readily accessible. If you need to replace a part at any stage of the design process, you have the tools to trace the part and estimate the impact with the where-used functionality.

Core Features of Altium 365

Cloud Libraries

The components library is one of your most valuable design assets. Ensure its integrity and manage your components in one central and secure location. Everyone working on a board design can use the same set of validated components. Component templates standardize component creation and ensure all the required parameters are populated. Accurate component lifecycles ensure your team knows which components can be used in a design and which are obsolete, reducing respins, and accelerating electronic product development.

Web Viewer

Deliver higher quality products to market faster than your competitors with transparent design reviews and sharing. Share the real-time state of projects with team members, manufacturers, and even customers. Collaborators can review and mark up your designs without ever leaving your design space. Anyone with internet access can view, search, cross-probe, and comment on your project from a browser, with no additional ECAD software licenses required.

Cloud Storage & Hardware Version Control

All your libraries and design data are in one secure workspace with granular access control so everyone can access the right design data at the right time. The system is built with the Git version control system under the hood and optimized for hardware development. Enjoy full traceability and transparency by knowing who made changes to the project, when, and why. Quickly identify what changed with a visual diff designed for hardware. Easily revert to previous versions if needed, and never wonder again whether the “v4_final2” is truly the final version.

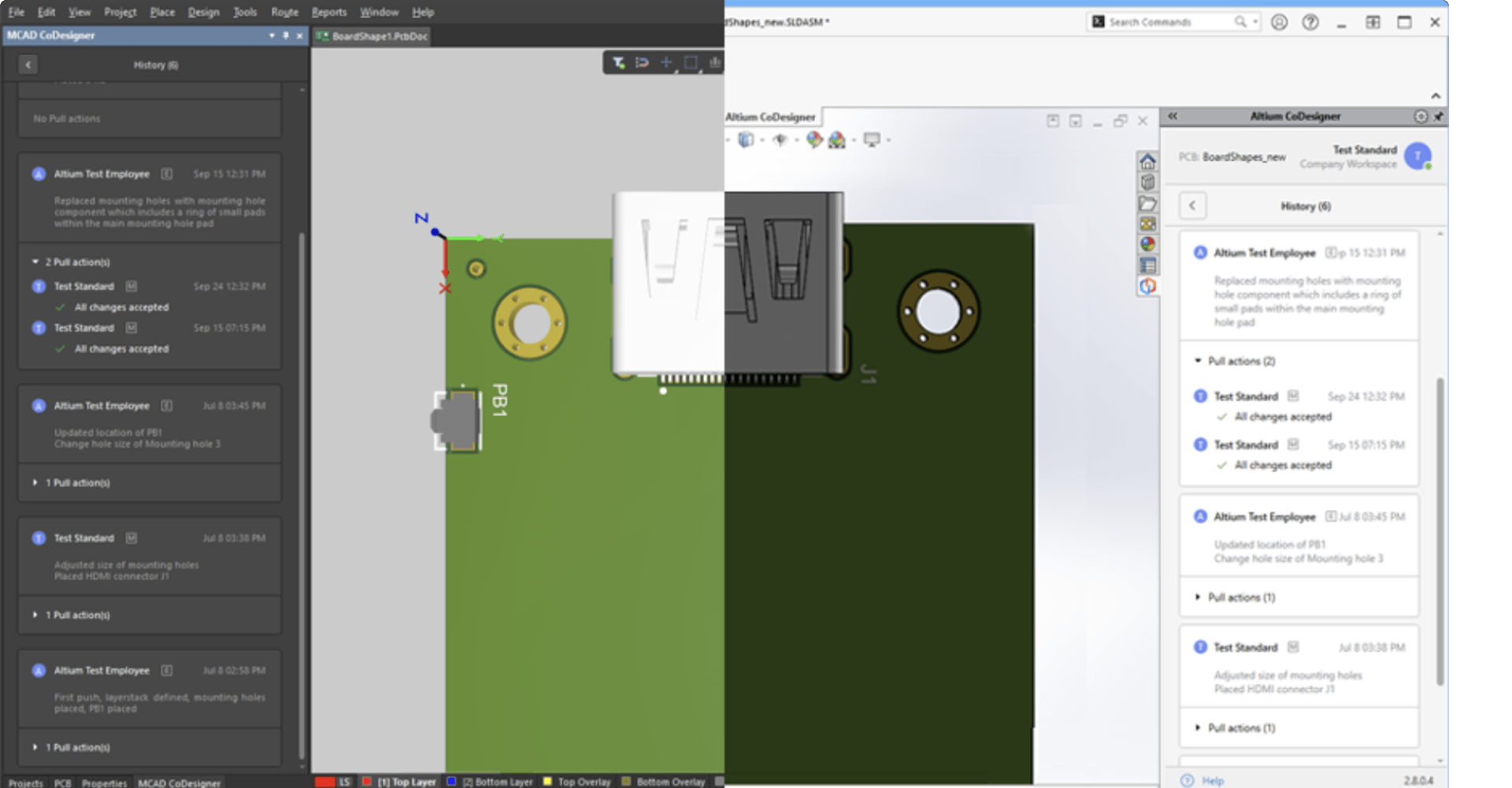

ECAD-MCAD Integration

Turn electronic and mechanical collaboration challenges into a competitive advantage with ECAD-MCAD collaboration. Work across domains seamlessly without loss of intent or time. Bi-directional data transfer between your ECAD and MCAD tools makes it easy to collaborate with your mechanical team and share design revisions as they happen. Native ECAD-MCAD integration with Inventor®, SOLIDWORKS®, and PTC Creo® is up to 10x faster than your typical error-prone data exchange methods.

Applications

Requirements Manager

Connecting design data and requirements for faster design with fewer errors

ECAD Connectivity

Manage all your ECAD files in Altium 365

Design Review

Accelerate your design reviews, track everyone’s feedback in real-time, and prevent errors for higher-quality products.

SiliconExpert

Upgrade your BOM management process with the SiliconExpert integration

Z2Data

Upgrade your BOM management process with the Z2Data integration

MCAD CoDesigner

Easily synchronize your design between Altium Designer and the most popular MCAD systems

Configurable Workflows

Accelerate your team by standardizing your workflows and guiding your designers through typical, everyday processes

BOM Portal

Enhance your BOM workflow: manage, resolve, consolidate, and order faster than ever

Assembly Assistant

Fast and accurate manual prototype board assembly

Cloud PLM Integration

Optimize your existing PLM investment by connecting into your electronic design

GovCloud

A dedicated region of Altium 365 situated within the US, operated exclusively by US Persons in the AWS GovCloud region that can help organizations comply with various US government regulations, such as ITAR and EAR