Wire Bonding in Altium Designer

ワイヤーボンディングの主な目的は、半導体チップとそのパッケージ間、またはマルチチップモジュール内の異なるチップ間に、安全で低抵抗の電気接続を確立することです。このプロセスでは、通常は金、アルミニウム、または銅で作られた細いワイヤーを、チップのボンドパッドからパッケージ基板または別のチップの対応するパッドに接続します。

ワイヤボンディングは、基板とチップの間で電力と信号を伝達します。これは、チップの接触面(パッド)とチップキャリアまたは基板との間に、マイクロワイヤのマイクロ溶接によって電気的接続が確立される基本技術です。一般的には、最もコスト効率が高く柔軟な相互接続技術と見なされ、ほとんどの半導体パッケージの組立てに使用されます。

Altium Designerは、ワイヤーボンディングを使用したチップオンボード(CoB)技術を用いてハイブリッドボードの設計をサポートしています。この機能により、定義されたダイパッドを持つコンポーネントを作成し、回路図に配置してPCBに同期(ECOを通じて)させると、メインボード上の通常のパッド(または任意の銅)にボンドワイヤーで接続できます。通常のパッドに接続されると、そのパッドはボンドフィンガーパッドの形状を呈します。

チップオンボード部品フットプリント作成

コンポーネントフットプリントの一部として、定義されたダイパッド、ボンドフィンガーパッド、ボンドワイヤーを持つ完全なシンプルパッケージを定義できます。

ダイパッドとダイ3Dボディは、専用のDieコンポーネントレイヤーペアの層に配置されます。この種のコンポーネントレイヤーペアは、View Configurationsパネルを使用して追加できます。

コンポーネントレイヤーペアの追加について詳しく学ぶ。

ダイパッドは、Die層(ダイボディと呼ばれる)上の押出しされた3Dボディに配置されます。ダイパッドは、ダイボディのOverall Heightに自動的に配置され、高さによってそれに結合されます。

|

ダイパッドは、Dieタイプのレイヤーに配置されたパッドオブジェクトです。 全高10ミルの押出し3DボディがDieタイプの層の上に配置され、ここではダイとして機能します。ダイパッドはこの3Dボディに配置されています。 3Dでは、ダイパッドはこれらのパッドが置かれる3Dボディの高さでレンダリングされます。 |

銅層(例:Top Layer)に配置された通常のパッドオブジェクトを置きます。それらにボンドワイヤーを接続した後、これらのパッドはボンドフィンガーパッドと見なされます。ボンドフィンガーパッドには、ダイパッドに割り当てられた設計者とは異なる設計者を割り当てることをお勧めします。

この例では、ダイの周りのトップレイヤーに配置されたパッドが接続用フィンガーパッドとして機能します。

ボンドワイヤーは、View Configurationsパネルを使用して追加できる専用Wire Bondingコンポーネントレイヤーペアの層の上に配置されます。

Place » Bond Wireコマンドを使用するか、Active Barのアイコン![]() をクリックしてボンドワイヤーを配置します。コマンドを選択した後、ボンドワイヤーで接続したい2つの点(例:ダイパッドの中心点とフィンガーパッドの中心点)を順にクリックします。直線は、ボンドワイヤーのXY平面への投影として2Dで表示されます。3Dでは、ボンドワイヤーはその始点と終点の位置およびその他のプロパティに基づいてレンダリングされます。

をクリックしてボンドワイヤーを配置します。コマンドを選択した後、ボンドワイヤーで接続したい2つの点(例:ダイパッドの中心点とフィンガーパッドの中心点)を順にクリックします。直線は、ボンドワイヤーのXY平面への投影として2Dで表示されます。3Dでは、ボンドワイヤーはその始点と終点の位置およびその他のプロパティに基づいてレンダリングされます。

|

2Dでは、接続されたボンドワイヤーは直線として示されます。ダイパッドとフィンガーパッドを接続するボンドワイヤーがここに示されています。 3Dで表示された同じボンドワイヤー。 |

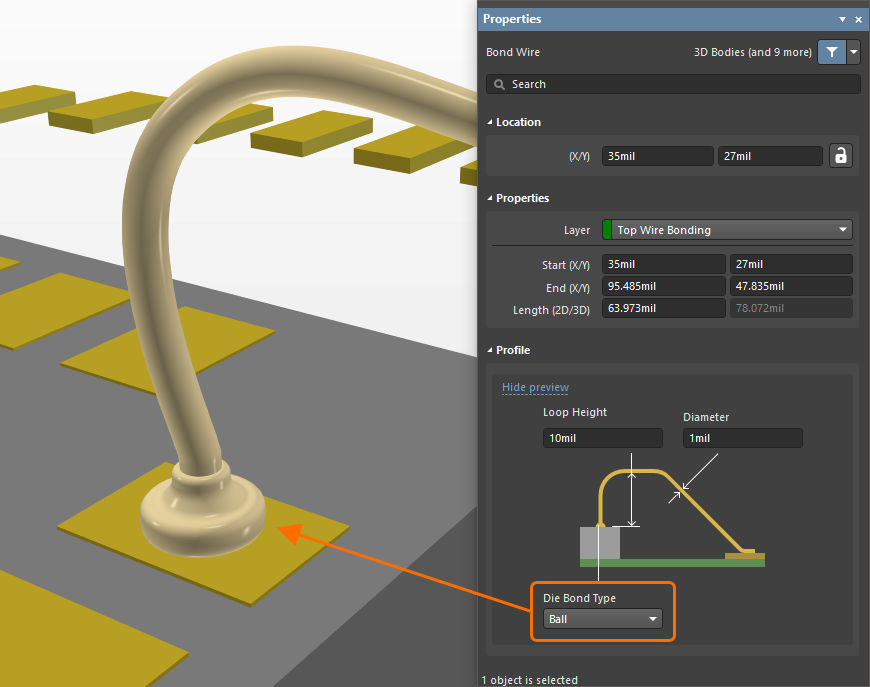

PropertiesパネルのProfile領域にあるフィールドを使用して、ボンドワイヤのLoop HeightとDiameter、ならびにボンドワイヤの始点の形状(BallまたはWedge)を定義するDie Bond Typeの希望値を指定します。

もしボンドフィンガーパッドが、パッドの長い面が接続されたボンドワイヤーと平行になるように配置する必要がある場合は、ボンドワイヤーと接続されたボンドフィンガーパッドを選択し、選択した状態で右クリックして、右クリックメニューからPad Actions » Align Bond Finger with Bond Wireコマンドを選択できます。

ワイヤーボンディングを特徴とする完全なフットプリントの例は、以下に示されています。

PCBにワイヤーボンドを配置する

チップ・オン・ボードアプローチを使用する際には、上記で説明したのと同様に、手動でボンドワイヤーを配置して、チップのダイパッドをメインボードの任意の銅に接続することもできます。ボンドワイヤーは、そのソースダイパッドのネットを継承します。同じダイパッドから複数のボンドワイヤーが発生することができ、逆に、複数のボンドワイヤーが同じメインボードの銅に接続されることもあります。

ワイヤーボンディングを特徴とするPCBの例が以下に示されています。

ワイヤーボンディングのための設計ルールチェック

Wire Bonding設計ルール(Routingカテゴリー)は、PCBにアクセスした際のAll Rulesビューと、制約マネージャーおよびPCBルールと制約エディターダイアログ(古いアプローチの設計ルール定義と管理を使用する場合)で定義できます。このルールにより、隣接するボンドワイヤー間の許容距離(Wire To Wire)、Min Wire LengthおよびMax Wire Length、そしてBond Finger Margin(ボンドワイヤーとそれが配線されるボンドフィンガーパッドの端との間の距離/パディング)に対する制約を定義できます。Wire Bonding設計ルールは、バッチDRCによってサポートされています。

PCB Rules and Constraints Editorダイアログで定義されたワイヤーボンディングルール

電気的ルールチェック(未配線ネットおよびショートサーキット)もワイヤーボンディングに適用されます。

|

Wire Bondingルール違反の例(2D)で、2本のボンドワイヤーがルールで許可された距離よりも近くに配置されています。 Wire Bondingルール違反の例(3D)で、2本のボンドワイヤーがルールで許可された距離よりも近くに配置されています。 Un-Routed Net規則違反の例で、ダイパッドと同じネットのトラックの間にボンドワイヤーが存在しない場合です。 Short Circuit規則違反の例:ボンドワイヤーが異なるネットのトラックに接続されている場合 |

ワイヤーボンディングクエリキーワード

設計ルールの範囲を作成する際、およびPCBまたはPCBライブラリ内のオブジェクトをフィルタリングするためにクエリ式を構築する際に、制約マネージャーおよびPCBルールと制約エディター ダイアログの両方で使用できるクエリ言語キーワードは以下の通りです:

-

IsBondFinger – 銅層上のSMDパッドプリミティブで、それにボンドワイヤーが接続されているものを返します。

-

IsBondWireConnected – ボンドワイヤーが接続されている任意のプリミティブを返します。

ドラフツマンドキュメント内のワイヤーボンディング

ドラフツマンは、通常のボードアセンブリビュー(メインのチップ・オン・ボードアプローチ用)と、ワイヤーボンディング「パッケージ」がフットプリント内で完全に定義されている場合のコンポーネントビュー(両方でワイヤーボンディングをサポートします。

-

選択したボードアセンブリビューのPropertiesパネルのLayersタブで、ダイパッドとボンドワイヤーのレイヤーを有効にして、これらのレイヤーをビュー(および派生したボード詳細ビュー)に表示します、以下に示されています。

-

コンポーネントがワイヤーボンディング(つまり、ダイパッドとそれに接続されたボンドワイヤーがある)を特徴とする場合、選択したコンポーネントビューのBond WiresおよびDie PadsオプションがPropertiesパネルのProperties領域で利用可能になります。これらのオプションを使用して、ボンドワイヤーの投影とダイパッドのグラフィックスを有効にします。

ワイヤーボンディング出力

通常のPCBプリントを生成する際にワイヤーボンディング情報がサポートされます。印刷するレイヤーとデザインatorを設定することで、ワイヤーボンディング図を作成できます。

ワイヤーボンディング図として構成されたPCBプリントの例です。

また、ボンドワイヤ接続に関する情報を提供するWire Bonding Table Reportを生成することができます(CSV形式)。出力ジョブファイルのAssembly Outputs領域からのワイヤボンディングテーブルレポートの出力を使用して、このタイプの新しい出力を追加します。あるいは、PCBエディタのメインメニューからFile » Assembly Outputs » Wire Bonding Table Reportコマンドを選択して、エディタから直接レポートを生成します。

Outjobファイルに新しいワイヤボンディングテーブルレポート出力を追加してください。

生成されたワイヤーボンディングテーブルレポートの例

)のボンドフィンガーパッドの両方にマッピングすることを推奨します。ピンマッピングの詳細については、

)のボンドフィンガーパッドの両方にマッピングすることを推奨します。ピンマッピングの詳細については、

AI で翻訳

AI で翻訳