Preparing Outputs and Releasing the Project

Main page: Preparing Your Design for Manufacture

Now that you have completed the design and layout of the PCB, you are ready to produce the output documentation needed to get the board reviewed, fabricated, and assembled.

Because a variety of technologies and methods exist in PCB manufacture, Altium Designer has the ability to produce numerous output types for different purposes, including Gerber files, ODB++ files, Pick and Place files, Bill of Material reports, etc.

Adding an Output Job File to the Project

Main page: Preparing Manufacturing Data with Output Jobs

While you can selectively generate the required outputs from specific editors (e.g., using commands in the Fabrication Outputs and Assembly Outputs sub-menus of the File main menu in the PCB editor), Altium Designer provides support for Output Job files. An Output Job file (or 'OutJob' for short) stores settings for each output type. An OutJob allows you to configure each output type, configure their output naming, format, and output location. Outputs can be generated from an OutJob directly or as a part of the integrated project release process.

-

Right-click the project entry in the Projects panel and select the Add New to Project » Output Job File command from the context menu. A new Output Job file will open and an entry for it will appear linked to the project in the Projects panel under the Settings\Output Job Files entry.

-

Right-click the OutJob entry in the Projects panel and select the Save As command. The Save As dialog will open, ready to save the document in the same location as the project file. Type the name

Fabricationin the File name field and click the Save button. -

Adding the OutJob has changed the project, so save the project locally by right-clicking the project entry in the Projects panel and selecting Save.

Adding and Configuring Fabrication Outputs

Main page: Preparing Fabrication Data

In this part of the tutorial, you will configure the outputs required to fabricate the board: Gerber and NC Drill files.

-

To add a new Gerber output, click the Add New Fabrication Output link in the Fabrication Outputs section of the OutJob's Outputs region and select Gerber Files » [PCB Document].

-

Double-click the added Gerber Files output entry. The Gerber Setup dialog will open. Configure options in the dialog as follows:

-

Since the board has been designed in metric, make sure that the Units option is set to Millimeters.

-

The smallest unit used on the board is 0.25mm for the routing and clearance, but because most of the components have their reference point at their geometric center (and were placed on a 1mm grid), some of their pads will actually be on a 0.01 grid. Set the Decimal option to 0.001 mm. This ensures that the resolution of the output data is more than adequate to cover these grid locations.

-

Click the

button at the bottom of the Layer to plot tab and choose Select Used. The layers that are used in the design will be enabled in the Plot column of the grid above.

button at the bottom of the Layer to plot tab and choose Select Used. The layers that are used in the design will be enabled in the Plot column of the grid above.

-

-

Click Apply to accept the other default settings and close the Gerber Setup dialog.

-

Because the board has holes, an NC Drill file also needs to be generated. Same way, add the NC Drill output to the OutJob file – click the Add New Fabrication Output link in the Fabrication Outputs section of the OutJob's Outputs region and select NC Drill Files » [PCB Document].

-

Double-click the added NC Drill Files output entry to access the NC Drill Setup dialog. To ensure that NC Drill files will be created in the same format as the Gerber files, set the Units to Millimeters and the Format to 4:3. Make sure that the Coordinate Position option is set to Reference to relative origin.

-

Click OK to accept the other default settings and close the NC Drill Setup dialog.

-

Now that the Gerber and NC Drill settings are configured, the next step is to configure their naming and output location. This is done by mapping them to an output container on the right side of the OutJob. For discrete files with their own file format, use a Folder Structure container. A new OuJob includes some containers by default. Select the Folder Structure entry in the list of output containers, then click the radio buttons for the Gerber and NC Drill Files in the Enabled column of the Outputs region to map these outputs to the selected container, as shown below.

-

The last step is to configure the container. To do this, click the Change link in the container entry when it is selected to open the Folder Structure settings dialog. At the top of the dialog, there is a set of controls that are used to configure the output location. Make sure that the first control is set to Release Managed. The lower part of the dialog will display how the names and folder structure change as you select different options.

-

Click OK to close the Folder Structure settings dialog.

Adding and Configuring a DRC Validation Report

Main page: Preparing Validation Reports

Altium Designer includes a number of validation checks, which can be included as an output, during output generation. Each produces an HTML report file. During the project release process, these checks will be performed prior generation of other outputs, and if any validation checks are not passed successfully, the release will fail.

-

To add a new DRC validation output, click the Add Validation Output link in the Validation Outputs section of the OutJob's Outputs region and select Design Rules Check » [PCB Document].

-

Map the added report to the existing Folder Structure container. Select the Folder Structure entry in the list on the right side of the OutJob, then click the radio button for the Design Rules Check output in the Enabled column of the Outputs region.

-

Save the Output Job file locally by right-clicking its entry in the Projects panel and selecting Save from the context menu.

-

Close the Output Job file by right-clicking its tab at the top of the design space and selecting the Close Fabrication.OutJob command from the context menu.

Adding and Configuring Assembly Outputs

Main page: BOM Configuration in the Report Manager

The actual output BOM file that is generated is done using the Report Manager dialog – a highly configurable report generation engine that can generate output in a variety of formats including text, CSV, PDF, HTML, and Excel. Excel-format BOMs can also have a template applied using one of the pre-defined templates or one of your own.

-

Add a new OutJob file to the project by right-clicking the project entry in the Projects panel and selecting the Add New to Project » Output Job File command from the context menu.

-

Right-click the OutJob entry in the Projects panel and select the Save As command. The Save As dialog will open, ready to save the document in the same location as the project file. Type the name

Assemblyin the File name field and click the Save button. -

Save the project locally by right-clicking the project entry in the Projects panel and selecting Save.

-

To add a new BOM output, click the Add New Report Output link in the Report Outputs section of the OutJob and select Bill of Materials » [ActiveBOM Document].

-

Double-click the added Bill of Materials output to open the Report Manager dialog.

-

In the Export Options region of the Properties pane on the right side of the dialog, use the File Format drop-down to select Generic XLS (*.xls, *.xlsx, *.xlsm) and then use the Template drop-down to select the BOM Template Single Supplier template from those that reside in your Workspace.

-

Click OK to save changes and close the Report Manager dialog.

-

Add a new Draftsman output by clicking the Add New Documentation Output link in the Documentation Outputs section of the OutJob and selecting Draftsman » All Draftsman Documents.

-

Map the added BOM and Draftsman outputs to the existing PDF output container. To do this, select the PDF entry in the list of output containers on the right side of the OutJob then click the radio buttons for the Bill of Materials and Draftsman outputs in the Enabled column of the Outputs region.

-

When the PDF container entry is selected, click the Change link in the entry to open the PDF settings dialog.

-

Click the Assembly.PDF entry at the top of the PDF settings dialog, select the Separate file for each output using output name, and click the

button. The output BOM and drawing will be assigned the name that is set to the output in the OutJob (Bill of Materials.pdf and Draftsman.pdf, respectively), which can be seen in the Preview region of the dialog.

button. The output BOM and drawing will be assigned the name that is set to the output in the OutJob (Bill of Materials.pdf and Draftsman.pdf, respectively), which can be seen in the Preview region of the dialog.

-

Click OK to close the dialog.

-

Add a new Pick & Place output by clicking the Add New Documentation Output link in the Documentation Outputs section of the OutJob and selecting Generates pick and place files » [PCB Document].

-

Double-click the added Generates pick and place files output to access the Pick and Place Setup dialog.

-

In the Output Setting region on the bottom left part of the dialog, set the Units to Metric.

-

Click OK to accept the other default settings and close the Pick and Place Setup dialog.

-

Map the added Pick & Place output to the existing Folder Structure output container. To do this, select the Folder Structure entry in the list of output containers on the right side of the OutJob then click the radio button for the Generates pick and place files output in the Enabled column of the Outputs region.

-

Save the Output Job file locally by right-clicking its entry in the Projects panel and selecting Save from the context menu.

-

Close the Output Job file by right-clicking its tab at the top of the design space and selecting the Close Assembly.OutJob command from the context menu.

Releasing the Project

Main page: Design Project Release

With output documentation configured in Output Job files, the project is ready to be released to the connected Workspace. The board design release process is automated, enabling you to release your board design projects without the risks associated with manual release procedures. When a particular project is released, a snapshot of the design source is taken and archived along with any generated output – which represents a tangible product that is made from that design project and sold by the company.

The release process itself is performed using Altium Designer's Project Releaser, the user interface to which is provided courtesy of a dedicated view – the Release view. The release process is a staged flow, with the entries on the left-hand side of the view showing you at-a-glance, which stage you are currently at.

-

Right-click the project entry in the Projects panel and select the Project Releaser command from the context menu. The Release view will open as a separate document tab.

-

In the first stage – 1. Configure Server Release – you specify the type(s) of data that you wish to generate. Click on Details controls at the far right of each data set header to access details of what exactly is going to be generated by a data set.

-

Click the

button at the bottom left of the view to access the Project Release Options dialog. On the dialog's Release Options tab, make sure that the Managed - <WorkspaceName> is selected as the Release Target, Fabrication is assigned to Fabrication Data set, and Assembly is assigned to the Assembly Data set.

button at the bottom left of the view to access the Project Release Options dialog. On the dialog's Release Options tab, make sure that the Managed - <WorkspaceName> is selected as the Release Target, Fabrication is assigned to Fabrication Data set, and Assembly is assigned to the Assembly Data set.

-

Click OK to close the dialog and return to the Release view.

-

Make sure that both Include Fabrication Data and Include Assembly Data for No Variant options are enabled.

-

Click the

button at the bottom right of the view to proceed.

button at the bottom right of the view to proceed.

-

The Item Creation dialog will open, with the list of target release items to be created in the Workspace. Select the Create items option to confirm item creation.

-

In the Project Modified dialog that opens, select the Save and Commit changes option to save the changes locally and proceed with saving the changes to the Workspace.

-

In the Commit to Version Control dialog that opens, enter a meaningful comment into the Comment field (e.g.,

The project is ready for release), then click the button.

button.

-

The next stage of the release process – 2. Validate Project – is run automatically because the

FabricationOutput Job file includes the Desing Rules Check report. -

After successful validation, the next stage of the release process – 3. Generate Data – is run automatically. This is where all other outputs – defined in the OutJob file(s) assigned to the included data items – are run, to generate the data to be released into the relevant target items in the Workspace.

-

With all validation checks passed and output data generated, the next stage of the release process – 4. Review Data – allows you to review the generated data. Proceed with the release by clicking the

button at the bottom right of the view.

button at the bottom right of the view.

-

The Confirm Release dialog will open, summarizing the configurations of the project that will be released to the Workspace. Enter a Release Note (e.g.,

Initial Release), and click OK.

-

After confirming the release in the previous stage, the next stage – 5. Upload Data – is automatically entered. It simply presents the progress of data upload into the revisions of the relevant data Items in the Workspace.

-

The final stage of the process – 6. Execution Report – provides a summary of the release. Close the Release view by clicking the

button at the bottom right of the view.

button at the bottom right of the view.

Collaborative Design with a Workspace

More often than not, multiple people are involved in the design and development of an electronic product. To do this effectively, the members of that design team need to be able to work collaboratively. Altium Designer, in conjunction with a connected Workspace, supports a number of collaborative design features. Some of them are listed below.

-

Project history – a dedicated History view is an advanced graphically orientated project history timeline that provides a progressive timeline of major events relating to the project – its creation, commits, releases, clones, and MCAD exchanges – with various actions supported where applicable The History view for a Workspace project can be accessed from Altium Designer by right-clicking the project entry in the Projects panel and selecting the History & Version Control » Show Project History command from the context menu.

Learn more: Project History, Project History (Altium 365 Workspace, Enterprise Server Workspace)

-

Web Viewer – the Workspace's Web Viewer interface provides universal access to project documents through a standard browser. Much more than just a browser-based viewer, its advanced browser technology allows users to navigate through the project structure, interact with design documents, highlight areas or objects for commenting notes, and search, cross-probe, select, and inspect components and nets throughout the design. The Web Viewer for a Workspace project can be accessed from Altium Designer by right-clicking the project entry in the Projects panel and selecting the Show in Web Browser command from the context menu.

Learn more: Web Viewer (Altium 365 Platform, Enterprise Server Workspace)

-

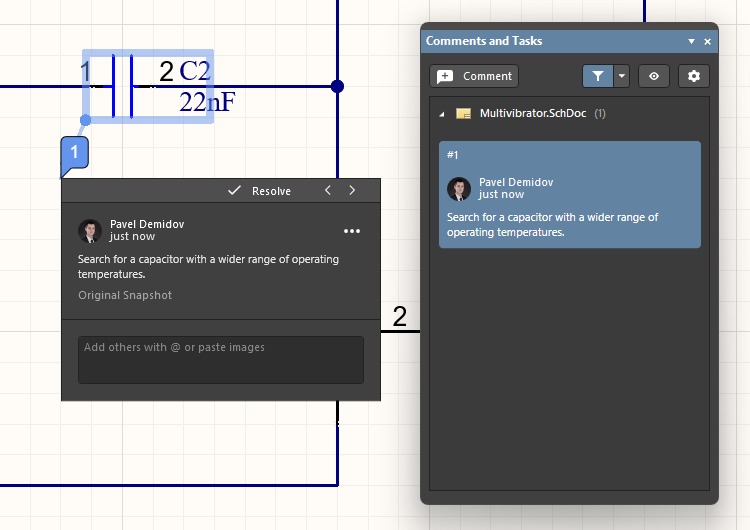

Document commenting – a comment is a user-added note that is assigned to a specific point, object, or area (as applicable) on a supported data view and may be replied to by other users. Comments promote collaboration between users without altering the shared data itself because comments are stored by the Workspace independently of that data. Comments applied in the Web Viewer interface in the following places become available in Altium Designer and vice-versa. In Altium Designer, the commenting feature is managed through the Comments and Tasks panel

Learn more: Document Commenting, Web Viewer (Altium 365 Platform, Enterprise Server Workspace)

-

Sharing a project – once a project is saved to the Workspace, you can determine which users can actually access that project, for collaborative design and/or reviewing this project. This is done by sharing the project, or rather, by configuring its access permissions. In Altium Designer, project sharing is managed through the Share dialog accessed by right-clicking the project entry in the Projects panel and selecting the Share command from the context menu.

Learn more: Sharing a Design, Workspace Projects (Altium 365 Workspace, Enterprise Server Workspace)

).

). ).

). )

)