Electronic design is the process of capturing a logical design in the schematic then representing that design as a set of objects in the PCB design space. Even for a small circuit, the schematic can include many components, each with numerous models and parameters. The PCB design space can also contain a large number of design objects that make up the board. During the course of the design process, the placement and properties of these objects need to change as you work to balance out the various design requirements.

Object Placement and Editing Commonality

In Altium Designer, the process of placing an object is roughly the same regardless of the object being placed. At its simplest level, the process is as follows:

-

Select the object to be placed by:

-

Selecting the command from the Place main menus.

-

Selecting the command from the Active Bar.

-

Right-clicking in the design space then selecting the command from the Place sub-menu of the context menu.

-

Use the mouse to define the location of the placed object in the schematic editor design space and its size (where applicable).

-

Right-click (or press Esc) to terminate the command and exit placement mode.

Schematic design objects can be placed outside the schematic sheet boundaries, and such objects can be selected and moved. When an object outside schematic sheet boundaries is selected, the same set of operations and commands can be performed as for an object within the schematic sheet boundaries.

Placing Design Objects

The basic steps for placing schematic design objects are outlined below.

-

Select the object type that you want to place by selecting an object type from the Place menu (e.g., Place » Wire) or by clicking on one of the icons on the Active toolbar. Shortcut keys for placement are also available (e.g., P, W to place a wire). To place components (parts), you can also click the Place button in the Components panel, or select the component name from an available library in the Components panel and drag it into the document.

-

When an object is selected for placement, the cursor will change to a crosshair, indicating that you are in editing mode, and if relevant, the object will appear "floating" under the cursor.

-

Press the Tab key to edit the properties of the object before placing it. This will open the Properties panel for that particular object, allowing you to change various options. Once you have finished setting the properties, click

to return to placement mode. The advantage of editing during placement is that objects that have a numeric identifier, such as a designator, will auto-increment.

to return to placement mode. The advantage of editing during placement is that objects that have a numeric identifier, such as a designator, will auto-increment.

-

Position the cursor then left-click or press Enter to place the object. For complex objects, such as wires or polygons, you must continue the position-and-click procedure to place all vertices of the object.

Note: The options on the

Schematic - AutoFocus page of the

Preferences dialog control the state of the schematic display. For example, the schematic can be configured to automatically zoom in when placing or editing connected objects or dim all wiring not related to the wire currently being placed. Other zooming and panning options are available using the shortcut keys or mouse wheel. Use the

Ctrl key and scroll the wheel mouse to zoom in and out, push the wheel button down and move the mouse up to zoom in or move the mouse down to zoom out when placing. You can set up the behavior of your mouse on the

System - Mouse Wheel Configuration page of the

Preferences dialog.

-

After placing an object, you will remain in placement mode (indicated by the crosshair cursor), allowing you to immediately place another object of the same type. To end placement mode, right-click or press the Esc key. In some cases such as placing a polygon, you may need to do this twice; once to finish placing the object and once to exit placement mode. When you exit placement mode, the cursor will return to its default shape.

Editing Prior to Placement

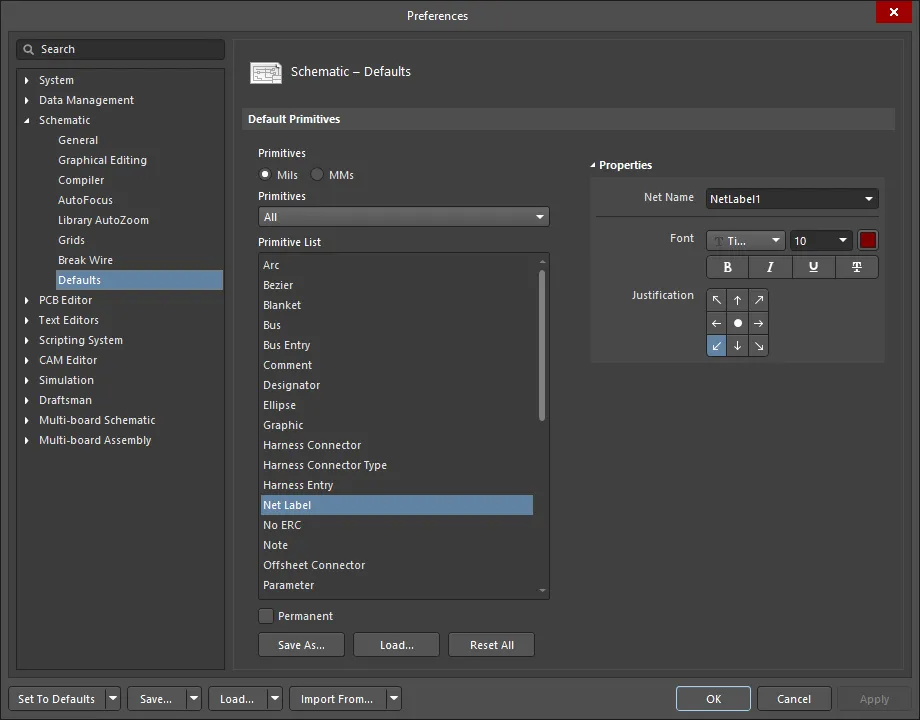

The default properties for an object (those that can logically be pre-defined) can be changed at any time on the Schematic – Defaults page of the Preferences dialog. These properties will be applied when placing subsequent objects.

Use the Primitive List column to access properties for objects and edit default values as required.

Default values for the objects are saved, by default, in the file Advsch.dft. Optionally, values can be saved in a .dft file with a different name. Controls are available to save and load .dft files, enabling you to create favorite default object value 'sets'. All settings saved in and loaded from .dft files are user-defined defaults. Should it be necessary, original default values can be brought back at any time using the Set To Defaults or Reset All options. The original default values are hard-coded.

Editing During Placement

A number of attributes are available for editing at the time an object is first placed. To access these attributes, press the Tab key while in placement mode to open the associated Properties panel. Pressing the Tab key pauses placement in order for you to make any required edits for the object.

Example Properties panel for a Net Label object.

After edits have been made, click the design space pause button overlay ( ) to resume placement.

) to resume placement.

Attributes that are set in this manner will become the default settings for further object placement unless the

Permanent option on the

Schematic – Defaults page of the

Preferences dialog is enabled. When this option is enabled, changes made will affect only the object being placed and subsequent objects placed during the same placement session.

Editing After Placement

Once an object has been placed, there are a number of ways in which it can be edited. These are described below.

The Associated Properties Panel or Dialog

This method of editing uses the associated Properties panel mode and dialog to modify the properties of a placed object.

After placement, the associated dialog can be accessed by:

-

Double-clicking on the placed object.

-

Placing the cursor over the object, right-clicking then choosing Properties from the context menu.

After placement, the associated mode of the Properties panel can be accessed in one of the following ways:

-

If the Properties panel is already active, select the object.

-

After selecting the object, select the Properties panel from the Panels button at the bottom right of the design space or select View » Panels » Properties from the main menus.

If the

Double Click Runs Interactive Properties option is disabled (default) on the

Schematic - Graphical Editing page of the

Preferences dialog, when the primitive is double-clicked or you right-click on a selected primitive then choose

Properties, the dialog will open. When the

Double Click Runs Interactive Properties option is enabled, the

Properties panel will open.

While the options are the same in the dialog and the panel, the order and placement of the options may differ slightly.

Press Ctrl+Q to toggle the units of measurement currently used in the panel/dialog between metric (mm) and imperial (mil). This only affects the display of measurements in the panel/dialog; it does not change the measurement unit specified for the sheet, which is configured in the Units setting in the Properties panel when there are no objects selected in the design space.

Graphical Editing

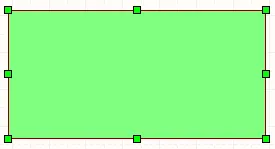

This method of editing allows you to select a placed object directly in the design space and change its size, shape, or location graphically. Modification of shape and/or size (where applicable) is performed through the use of editing 'handles' that appear once the object is selected.

Example editing handles for a selected Sheet Symbol object.

When an object is selected, you can move the object or edit its graphical characteristics. Click on an object to select it; its 'handles' or vertices are displayed. The selected object will be highlighted in the selection color defined in the Selections field of the Color Options region on the Schematic - Graphical Editing page of the Preferences dialog. To graphically change a selected object, click and hold on an editing handle. That point of the object will then become attached to the cursor. Move the mouse to a new location and release to resize. Click anywhere on a selected object to move it or press the Delete key to delete it.

Moving selected objects:

-

Selected schematic or PCB objects can be 'nudged' by the current snap grid value by pressing the arrow keys while holding down the Ctrl key.

-

Selected objects can also be 'nudged' by the snap grid value x10 by pressing the arrow keys while holding down the Ctrl+Shift keys.

-

For the schematic objects, the current Snap Grid is displayed on the status bar. The available Snap Grids are configured on the Schematic - Grids page of the Preferences dialog. Press G to cycle through the available grid values as you work.

-

For the PCB objects, the current Snap Grid is displayed on the status bar and is defined in the Grid Editor dialog. Press Ctrl+G to open the dialog and enter a new value.

-

You can select multiple PCB components and reposition them individually (in the order in which you selected them) using the Reposition Selected Components command (Tools » Component Placement » Reposition Selected Components or shortcut T, O, C). The components can be selected directly on the PCB using the PCB panel, or in the Schematic Editor if Cross Select Mode is enabled (Tools menu).

Repositioning an Object

Two terms are used to describe graphically repositioning an object: move and drag.

-

Move - to move the object(s) without regard to connectivity.

-

Drag - attempt to maintain connectivity while moving the object(s).

The schematic editor operates in one mode or the other, depending on the current state of the Always Drag option (Schematic - Graphical Editing page of the Preferences dialog).

The current state of the Always Drag option can be temporarily toggled as you work by holding the Ctrl key. If the Always Drag option is enabled and you Ctrl + click, hold and drag, the software will not attempt to maintain connectivity, instead moving the object under the cursor. In this situation, if that object is a member of a union, then all objects in the union will move. If you work with Always Drag enabled, hold Ctrl as you click and drag to move all objects in a union. Note that the Ctrl key works in both directions, if Always Drag is currently disabled, then holding Ctrl instructs the schematic editor to switch from move object behavior, to drag object behavior.

Click and hold on an object (or one of the objects in a selection) to reposition it. When you do, the cursor may snap to a different location on the object from where you clicked. This is intentional and is controlled by the following options, configured on the Schematic - Graphical Editing page of the Preferences dialog. Note that electrical objects, such as net labels, sheet symbols, and components, behave differently from non-electrical objects, such as a rectangle, or a line, if the Always Drag option is on.

-

Center of Object - when enabled, for a graphical object move the cursor and hold at the geometric center of the object. For an electrical object, hold at the click location if the Always Drag option is enabled. If Always Drag is off, hold at the geometric center. For text strings, hold by the string reference point (determined by the string's current Justification property setting).

-

Object's Electrical Hot Spot - when enabled, if the object is an electrical object, hold at a Hot Spot (the Hot Spot is the point where connectivity is created). When enabled, this option overrides the Center of Object option for electrical objects.

-

Always Drag - the term Drag is used to indicate movement while maintaining connectivity. When enabled, when you click and drag on an electrical object you are asking the software to attempt to maintain the current connectivity, and neatly adjust the wiring to suit as you drag. Hold Ctrl to temporarily switch from Dragging to Moving.

-

When Always Drag is enabled, the software attempts to maintain the connectivity currently defined in that net. Always Drag can be temporarily inhibited by holding Ctrl as you click and drag.

-

Press the G key during object movement to cycle through the available Grid Preset settings. These are configured in the Schematic - Grids page of the Preferences dialog.

-

Press the Ctrl key during text or graphical object movement to temporarily inhibit the current Grid Preset and set the grid to the minimum 10mil value This feature is useful when you need to carefully adjust the location of a text string.

-

Selected objects can be 'nudged' by one grid (according to the current snap grid value) by pressing the Ctrl+Arrow keys. Selected objects also can be 'nudged' by 10 grids (snap grid value by a factor of 10) by pressing the Ctrl+Shift+arrow keys.

-

Press the Alt key while moving, to constrain the direction of movement to the horizontal or vertical axis, depending on the initial direction of movement.

-

Press Ctrl+Spacebar to rotate the selection counterclockwise and in increments of 90°. Press Shift+Ctrl+Spacebar to rotate the selection clockwise.

-

Press the X or Y keys to flip the selection along the X-axis or Y-axis respectively.

-

Press the Spacebar (or Shift+Spacebar) to change the wiring mode for any connected wires, buses, or signal harnesses. The wiring mode for connected wiring can only be changed provided the Drag Orthogonal option is enabled, on the Schematic - General page of the Preferences dialog. The default mode is to keep wiring at 90 Degree angles. If this option is disabled, not only can the wiring mode not be cycled, the connected wiring will be repositioned obliquely.

Movement Commands

Object position can be changed using commands of the Edit » Move sub-menu of the main menus or the movement sub-menu in the Active Bar.

-

Drag - drag an individual object in the current document, while maintaining connectivity with other electrical objects (if an electrical object is chosen).

-

Move - move an individual object in the current document. Connectivity is not maintained when using this feature.

-

Move Selection - reposition selected objects on the current document. Connectivity is not maintained when using this feature.

-

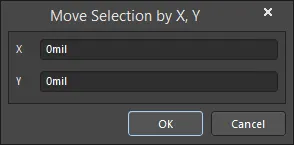

Move Selection by X, Y - offset the current selection of objects by a precise amount in X and/or Y directions. After launching the command, the Move Selection by X, Y dialog will appear. Use this dialog to specify delta X and/or delta Y increment values, by which to move the selection. After clicking OK, the selection will be moved accordingly.

The Move Selection by X, Y dialog

-

Drag Selection - drag selected electrical objects in the current document, while maintaining connectivity with other electrical objects. To use with a selection of non-electrical objects, hold the Ctrl key to commence movement. This has the effect of temporarily disabling the Always Drag option, switching the Drag Selection command to act as the Move Selection command. Note that the Ctrl key also inhibits snapping to the grid, release the Ctrl key once movement has commenced to reinstate grid snapping.

-

Move To Front - this command is used to reposition an object and place it at the front of all other objects in the drawing stack in the current document.

-

Rotate Selection - this command is used to rotate one or more selected objects in an counter-clockwise direction.

-

Rotate Selection Clockwise - this command is used to rotate one or more selected objects in a clockwise direction.

Alignment Commands

Objects can also be moved by changing their alignment. To align objects with other objects, select all objects you wish to involve in the alignment, right-click on a selected object, then select Align. Alternatively, use the Edit » Align sub-menu of the main menus or the alignment sub-menu in the Active Bar. The alignment sub-menu contains a number of options for distributing selected objects.

Connectivity is not preserved during alignment.

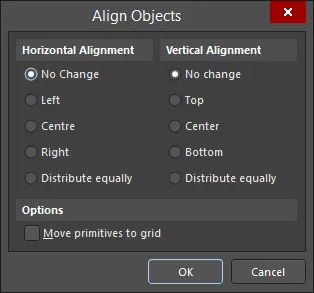

The Align command is used to access the Align Objects dialog, which provides controls for quickly aligning the set of currently selected design objects as required. Use the dialog to set options for both the vertical and/or horizontal alignment of the selected objects, as required, then click OK to effect alignment.

The Align Objects dialog

-

Enabling both Horizontal and Vertical options at the same time may result in a conflict, with the selected objects becoming stacked on top of one another.

-

Using the Distribute equally options can result in the moving objects being off-grid. Enable the Move primitives to grid option to restrict alignment such that all primitives in the selection will lie on a valid grid point after the alignment is complete.

Options and Controls of the Align Objects Dialog

-

Horizontal Alignment - choose from one of the following options to determine the horizontal alignment of the selected objects:

-

No Change - leave the horizontal alignment of the objects unchanged.

-

Left - align objects to the left edge of the left-most object.

-

Center - align objects on an axis mid-way between the left-most and right-most objects in the selection.

-

Right - align objects to the right edge of the right-most object.

-

Distribute equally - horizontally space the selected objects evenly, using the left-most and right-most objects as the left and right boundaries respectively.

-

Vertical Alignment - choose from one of the following options to determine the vertical alignment of the selected objects:

-

No Change - leave the vertical alignment of the selected objects unchanged.

-

Top - align objects to the top edge of the top-most object.

-

Center - align objects on an axis mid-way between the top-most and bottom-most objects in the selection.

-

Bottom - align objects to the bottom edge of the bottom-most object.

-

Distribute equally - vertically space the selected objects evenly, using the top-most and bottom-most objects as the top and bottom boundaries respectively.

-

Move primitives to grid - enable this option to restrict the alignment such that all primitives in the selection will lie on a valid grid point after the alignment is complete.

The Align Left / Align Right / Align Top / Align Bottom command enables you to align selected design objects by their left/right/top/bottom edges, respectively. After launching the command, the left/right/top/bottom edge of the left/right/top/bottom-most object is used as a reference, and all other objects in the selection will be moved left/right/top/bottom, so that their left edges are aligned with this reference.

Objects will be moved regardless of their position with respect to the reference. It is possible to end up with partial or total overlap of objects.

The Align Horizontal Centers / Align Vertical Centers command enables you to place selected objects in a single column/row, aligned by their horizontal/vertical centers. After launching the command, the objects in the selection will be moved horizontally/vertically to form a single column/row, aligned by their horizontal/vertical centers. The vertical center line for the column is the mid-point between the left-most and right-most objects in the selection; the horizontal center line for the row is the mid-point between the top-most and bottom-most objects in the selection.

The Distribute Horizontally / Distribute Vertically command allows you to make the horizontal/vertical spacing of a selection of objects equal. After launching the command, the left-most and right-most / top-most and bottom-most objects in the selection will remain fixed in their positions, with all other objects spaced equally between them. The vertical/horizontal position of the objects is not changed.

The Align To Grid command is used to move selected objects to the nearest point on the current snap grid.

Rounding Object Coordinates

You can round up the internal coordinates of objects, to counter any rounding effect when switching from Imperial to Metric measurement units mid-design, by choosing the Tools » Convert » Round coordinates of objects command, from the main menus. The overall result is that the internal coordinates of all design objects will be as they would have been, had you started designing with metric units from the outset.

After launching the command, the Rounding coordinates of objects dialog will appear. Use this dialog to define which documents the rounding process will be applied to:

-

Just this document - round coordinates only for the current document.

-

All schematic documents in the current project - round coordinates for all schematic documents of the current project. Schematic documents of the current project that are currently closed will be opened.

-

All open schematic documents - round coordinates for all the schematic documents that are currently opened regardless of the project to which they belong.

The Rounding coordinates of objects dialog

After you make your selection and click OK, an information dialog will open that summarizes how many objects on how many documents had their coordinates rounded.

Moving an Object in the Drawing Stack

The schematic editor automatically stacks objects, text and graphics in layers. Each object is on a different layer depending on the creation order and, therefore, it is possible to place objects so that they overlap. The objects created or added recently are always on the top layer.

Using the following commands of the Edit » Move sub-menu of the main menus or the movement sub-menu in the Active Bar, you move an object in an overlapping object stack of which this object is a part.

Bring To Front / Send To Back – move an object that is part of a stack of overlapping objects to the front/back of all other objects in that stack. After launching the command, click the object that you want to move. The object will be moved to the top/bottom of the stack in front of / behind all overlapping objects without changing its x or y coordinates.

Bring To Front Of / Send To Back Of – move one object in front of / behind another object in a stack of overlapping objects. After launching the command, click the object that you want to move, then click a 'target' object that you wish to move the first object in front of / behind. The first object will be moved in front of / behind this target object without changing its x or y coordinates.

When selecting the initial or target objects, if you click on an area where multiple possible objects overlap, a pop-up will appear containing all overlapping objects from which you can choose the desired object.

In-place Text Editing

The in-place text editing enables you to edit text entries on the current document, such as designator and comment text, text strings, text frames, and fully expanded notes, directly rather than having to edit through the Properties panel. To do so, click on the textual object once to select it, then after a short delay, click again to enter in-place editing mode (sufficient time between each click should be given to ensure the software does not interpret the two single-clicks as one double-click which would open the Properties panel). Alternatively, select the textual object on which to perform in-place editing then use the F2 keyboard shortcut. Select the text object that you wish to edit then activate the command - the text will be highlighted ready for direct editing.

To finish editing in-place text, click away from the text string. For parameter text or text string, you can also press Enter. For a text frame or note, you can press the green tick button  (if you decide the change made is not needed, press the red cross button

(if you decide the change made is not needed, press the red cross button  to discard the change).

to discard the change).

This feature is only available if the

Enable In-Place Editing option is enabled on the

Schematic - General page of the

Preferences dialog. If this option is disabled, you will have to select the parent object and edit the text through the

Properties panel.

The right-click menu provides standard editing commands such as Cut, Copy, Paste, and Delete.

Polyline Object Editing

A segment of a polyline connectivity object (wire, bus, or signal harness) placed on a schematic sheet can be broken into two pieces at a chosen location on the schematic sheet using the Edit » Break Wire command, from the main menus. After launching the command, the cursor will appear in accordance with settings defined for the Cutter Box, and Extremity Markers, on the Schematic - Break Wire page of the Preferences dialog.

If the cutter box is set to never be displayed, or only be displayed when the cursor passes over a polyline segment, the cutting area will be distinguished in the workspace through use of a central cross marker, while the cursor is away from a wire segment. If both cutter box and extremity markers are set to never display, passing the cursor over a wire segment will cause the relevant portion of that segment, or its entirety, to become highlighted - thus distinguishing the portion of wire that will be cut when clicked.

Position the cursor over the segment of wire, bus, or signal harness that you want to effectively break into two and click, or press Enter. The indicated length of segment will be removed, thereby breaking the segment into two.

Continue breaking further polyline objects, or right-click, or press Esc, to exit.

While in break wire mode, press the Spacebar to cycle through the following cutting length modes:

-

Snap To Segment - in this mode, the cutter will auto-size to snap to an entire polyline segment.

-

Snap Grid Size Multiple - in this mode, the cutter is sized to a defined multiple of the current snap grid.

-

Fixed Length - in this mode, the cutter is sized to a defined fixed length.

-

Regardless of the size of cutter, with options other than Snap To Segment, the cutter will shrink to accommodate smaller-sized wire segments in their entirety - as it passes over them - as though Snap To Segment were selected.

-

Properties for the cutting tool can be defined on the Schematic - Break Wire page of the Preferences dialog. Values modified at the local document level will be instantly reflected back at the preferences level.

-

You can also remove selected wire segments (not segments of bus or signal harness objects) with the tap of the Delete key, with auto-junctions also accounted for - allowing you to remove a segment of a wire up to that junction only (and including that junction if only two other wire segments would otherwise remain connected to it). Simply click twice (with a pause in between) on a particular segment of wire to select it, denoted by its end-point editing handes turning red. You can delete multiple segments across different wires, ensure that each is selected (Shift+click twice on each subsequent segment to include it in the overall segment selection).

To edit the specific vertex currently under the cursor, for the parent polygon, line, wire, bus, signal harness, or line object placed on a schematic sheet or a schematic symbol, the Edit <ObjectType> Vertex n command accessed from the right-click menu of the required vertex can be used. After launching the command, the dialog presenting the properties for the parent object will appear. The chosen vertex will be selected ready for editing in the Vertices region of the panel.

Using Cut/Copy and Paste

In the schematic editor, you can cut/copy and paste objects within or between Schematic Documents, e.g., component(s) from a schematic can be copied into another Schematic Document. You can cut/copy objects to the Windows clipboard and paste them into other documents. Text can be pasted from the Windows clipboard into a schematic text frame. You can also directly copy and paste a table-type selection from another application such as Microsoft Excel or from any grid style control within Altium Designer.

More advanced copy/paste actions can be performed using the Smart Paste feature.

Select the object(s) you want to cut/copy, click Edit » Cut (Ctrl+X) / Edit » Copy (Ctrl+C) from the main menus or choose the Cut/Copy command from the right-click menu then click to set a copy reference point on the object that will be used to accurately position the object during pasting. You will only be prompted to click to set a reference point if the Clipboard Reference option is enabled on the Schematic - Graphical Editing page of the Preferences dialog. If the Clipboard Reference option is disabled, it is advisable to use the shortcut to launch the command.

If you require the sheet template to be added as part of the copy (containing border, title block, etc.,), make sure that the Add Template to Clipboard option is enabled on the Schematic - Graphical Editing page of the Preferences dialog.

To copy the currently selected design object(s) to the clipboard in textual format, select the object(s) then choose the Edit » Copy As Text command from the main menus. The text of text-based objects in the selection (annotations, notes, text frames, net labels, offsheet connectors, ports, power ports, etc.) will be copied to the clipboard. This information can then be pasted into any text field or external text document.

To place the last content cut/copied to the clipboard, into the active document, choose the Edit » Paste command from the main menus or right-click within the design space and choose the Paste command from the context menu (shortcut: Ctrl+V).

When pasting copied component objects, their designators will reset if the

Reset Parts Designators on Paste option is enabled on the

Schematic - Graphical Editing page of the

Preferences dialog.

To copy one or more selected objects and then paste multiple instances of the selection wherever required in the current document, you can also use the

Edit » Duplicate command from the main menus (shortcut:

Ctrl+R). Because this command is used to copy and paste objects, you cannot use the command for duplicating the children of group objects.

Using Smart Paste

The schematic editor’s Smart Paste feature allows copies of a selected object to be optionally transformed and pasted as a different object. For example, a selection of Net Labels could be copied and Smart Pasted as Ports, or a group of selected Sheet Entries could be pasted as Ports+Wires+Net Labels with busses expanded into individual wires.

When the object(s) required for the smart paste operation have been copied to the clipboard, choose the Edit » Smart Paste command, from the main menus, or use the Shift+Ctrl+V keyboard shortcut to access the Smart Paste dialog.

The Smart Paste dialog

Options and Controls of the Smart Paste Dialog

Choose the Object to Paste

-

Schematic Object Type Grid - displays a list of all the objects in the clipboard you have selected grouped by their type. The check box allows you to control which set of objects you would like to paste. Before you can paste, you also need to select an operation from the Choose Paste Action region of the dialog. This determines how your selected objects will be placed onto your schematic sheet. The Themselves paste operation is a standard paste operation that pastes the objects as they were selected to the clipboard. The other operations allow you to transform the source object into a different object (or collection of objects) when pasting.

-

Windows Clipboard Contents Grid - the software uses its own clipboard. The Smart Paste operation allows you to control paste operations over the software's clipboard and also the Windows clipboard. Enable the contents in the Windows clipboard if you want to include these contents in the smart paste.

Choose Paste Action

-

Paste As - before you can paste, you need to select a paste operation. This determines how your selected objects will be placed onto your schematic sheet. The Themselves paste operation is a standard paste operation. The other operations allow you to transform the source object into a different object (or collection of objects) when pasting. The possible transformations are:

-

Ports, Sheet Entries, Net Labels can be transformed into equivalent ports, sheet entries, net labels, or one text frame/note or a port and net label set per object (with wires).

-

Label, Text Frame, Note can be transformed into Label, Text Frame, Note.

-

Windows Clipboard Text can be transformed into net labels, ports, sheet entries, labels, text frames, notes, possibly parts or a port and net label set per object (with wires).

-

Windows Clipboard Graphics can be transformed into an image.

-

Options - by choosing different Paste As objects, different options will be shown:

Paste Array

-

Enable Paste Array - enable to copy your selected objects as a two-dimensional array. The total number of copies you will create are the number of columns times the number of rows. After clicking OK, you will be prompted to select a start location on the document where the array will be inserted. Position the cursor at the desired location then click or press Enter.

-

Columns

-

Count - specifies the number of columns you want in your paste array. Each column is separated by the Column Spacing setting.

-

Spacing - enter positive or negative values for spacing to determine whether the array is pasted to the right or left for horizontal placement, or upwards or downwards for vertical placement.

-

Rows

-

Count - specifies the number of rows you want in your paste array. Each row is separated by the Row Spacing setting.

-

Spacing - enter positive or negative values for spacing, to determine whether the array is pasted to the right or left for horizontal placement, or upwards or downwards for vertical placement.

-

Text Increment

-

Direction - select which method you would like to use to increment strings (such as designators) on the copies you are pasting. You can select from the following options:

-

None - do not increment. Each copy will have the same strings.

-

Horizontal First - increment strings by increasing the value of a string from its predecessor by the Primary amount. The successor string to increment is found by finding the next string in the sequence immediately to the right. Once a row has been re-sequenced, move to the start of the next row above. Pins can also be incremented using the Secondary setting.

-

Vertical First - increment strings by increasing the value of a string from its predecessor by the Primary amount. The successor string to increment is found by finding the next string in the sequence immediately above. Once a column has been re-sequenced, move to the start of the next column to the right. Pins can also be incremented using the Secondary setting.

-

Primary - strings are incremented/decremented from its predecessor by the Primary amount. Pins can also be changed using the Secondary setting.

-

Secondary - strings are incremented/decremented from its predecessor by the Primary amount. Pins can also be changed using the Primary setting.

-

Remove Leading Zeroes - enable this option to remove the leading zeroes from the text string. For example, 000ABC is transformed as ABC if this option is enabled.

You can add a negative value in the spacing field so you can reverse the order of the placed objects

Use of the feature essentially requires the following three areas of the dialog to be configured as required:

-

Choose the objects to paste - this section displays a list of all the objects in the clipboard grouped by their type. Select the objects to paste using the check box beside each Schematic Object Type. Altium Designer maintains a separate clipboard to the main windows clipboard in order to have better resolution of the details of clipboard objects, but if required, the Windows Clipboard Contents can also be used as the source of a Smart Paste.

-

Choose Paste Action - before new objects can be pasted, an appropriate Paste As object needs to be selected to define how the selected objects will be transformed. Pasting objects as Themselves will perform a standard paste operation. The other options will transform the source object into the chosen object, or collection of objects, prior to pasting. Additional options, where available, will be listed below the chosen paste object(s).

-

Paste Array - enable this option to copy the selected objects as a two-dimensional array. The total number of copies created will be equal to the number of columns times the number of rows. For objects involving identifiers, use the Text Increment controls to determine how the Primary (and Secondary where applicable) identifiers are incremented. Use the Direction field to determine how incrementing is applied – Horizontal First or Vertical First. To obtain exact copies of the identifiers, with no incrementing, set the direction to None.

As you configure options in the Smart Paste dialog, a Summary region at the bottom of the dialog provides a useful overview of what is going to happen - what you are going to get pasted in the design space, based on the nominated clipboard content.

With the options configured as required, click OK. If no array is being placed, the content being pasted will appear floating on the cursor. Position the content at the required position within the design space and click, or press Enter, to paste.

Re-Entrant Editing

The Schematic Editor includes a powerful feature called re-entrant editing that allows you to perform a second operation using the keyboard shortcuts without having to quit the operation you are currently carrying out. For example, pressing the Spacebar when placing a part will rotate the object but will not disrupt the placement process. Once you place the part, another part will appear ready at the cursor already rotated.

Re-entrant editing is also very useful if you start placing a wire that needs to be connected to a port that you have not placed yet. There is no need to exit Place Wire mode; just press the Place Port shortcut keys (P, R), place the port, press Esc to exit Place Port mode and then connect the wire to the port.

Measuring the Distance on a Schematic Document

The Schematic Editor has a distance tool located in the Reports menu (Reports » Measure Distance as well as the Ctrl+M shortcut keys). You can use this tool to measure the distance between two points on a schematic document. After launching the command, you are prompted to click on two points on the schematic document. Once you have chosen two points, an Information dialog appears with an overall Distance value, with the X Distance and Y Distance values displayed accurate to two decimal places.

Change the Snap Grid (shortcut G) if you cannot accurately position the cursor at the required points.

The measurement units are determined by the Units chosen for the schematic document in the General region of the Document Options mode of the Properties panel. You also can switch to Imperial or Metric units by toggling the units (View » Toggle Units).

Editing Group Objects

A group object is any set of primitives that has been defined to behave as an object. For example, a component on a schematic is a collection of drawing objects, strings, parameters, pins, and references to models. The primitive objects that belong to a group object are sometimes referred to as the child objects and the group object is their parent object.

Let's look at a typical group object edit that you might want to perform. Your design includes several capacitors. Currently, the voltage is specified as part of the components' comment string. You need to change this and specify the voltage as a component parameter instead and make this parameter visible on the schematic.

The steps we need to perform are (described in detail below):

-

Select capacitors with a value of 100uF 16V.

-

Change their comment to be 100uF (remove the 16V text).

-

Add a new parameter to these components with a name of Voltage and a value of 16V.

-

Change the visibility of this parameter so it's displayed on the schematic.

While this might seem like a complex set of edits to perform, it is actually quite straightforward.

Step 1. Selecting the Capacitors

To select all the 100uF 16V capacitors, right-click on the component symbol of one of them then select Find Similar Objects from the context menu.

We will use the approach covered in the previous example, except this time you want to match on components that have the same Comment and the same Current Footprint as shown in the image above.

Note that we can also match on components that have a designator starting with the letter C. This is done by changing the Component Designator to C*. Click OK to select the matching capacitors.

Step 2. Changing the Comment String

After clicking OK, the Properties panel opens (if the Open Properties option in the Find Similar Objects dialog was enabled). Behind it will be the schematic sheet displaying the matching objects selected on that sheet. If the Zoom Matching and Mask Matching options were enabled, the view will be zoomed and all the objects that did not match are faded or masked out.

You can check the status line at the bottom of the Properties panel to see if the same capacitors exist on other sheets.

To change the comment string, delete 16V from the string then press Enter to apply the change.

Step 3. Adding a New Parameter to the Component

The next change that we need to make is to add a new parameter. To do this, click Add in the Parameters region of the Properties panel in Component mode then select Parameter from the drop-down. A Parameter 1 entry will be added to the grid in the region. Enter the new parameter Name and Value.

Click

to delete a selected parameter.

Step 4. Setting the Voltage Parameter to be Visible

The last step is to make the new Voltage parameter visible. Click the  icon to make the parameter visible (displays as

icon to make the parameter visible (displays as  ).

).

We have now updated the comment string for all 100uF capacitors. We have also added a new parameter called Voltage, set its value to 16V, and made this parameter visible.

Text Search

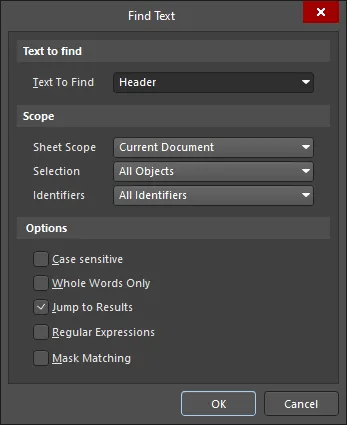

The schematic and schematic symbol editors allow you to quickly find specific text, or partial text, in accordance with defined search options. Choose the Edit » Find Text command from the main menus, right-click in the design space and select the Find Text command from the context menu, or use the Ctrl+F keyboard shortcut to access the Find Text dialog. Use this dialog to specify the existing text to find, along with scoping and additional options.

The Find Text dialog

Options and Controls of the Find Text Dialog

Text to find

Scope

Options

-

Case sensitive – enable this option to perform a case-sensitive search, meaning the target text must match the case of the search text entered into the Text To Find field.

-

Whole Words Only – enable this option to restrict the search to whole words only. This means the search text must exist fully as is and not be part of a larger text string. For example, if this option is enabled, when looking for "cat", the software will not consider the first three letters of "category" - a valid search match. Disable this option to freely search for partial strings.

-

Jump to Results – enable this option to have matching/found text zoomed and centered in the design space (where possible). Where a search yields multiple matches, the Find Text - Jump dialog opens. Use this dialog to jump between the matching search results.

-

Regular expressions – check to search using regular expressions.

-

^ – only match when the string is at the start of a line.

-

$ – only match when the string is at the end of a line.

-

. – indicates any single character (e.g., "te.t" matches "test", "text", and "tent", but not "tet").

-

* – indicates any set of characters, including no characters (e.g., "te*" matches "text", "tent", and "te", but not "t").

-

+ – indicates any set of characters, except no characters (e.g., "te+" matches "text", and "tent", but not "te").

-

[ ] – find any of the characters enclosed in the brackets.

-

[^] – a caret at the start of a string in brackets means NOT (e.g., "[^tes]" matches any characters except t, e, or s).

-

[-] – a hyphen within a string in brackets signifies a range of characters (e.g., "[l-o]" matches the characters l, m, n, and o).

-

{ } – used to group characters or expressions. Groups can be nested with a maximum number of 10 groups in a single pattern.

-

\ – a backslash before a wildcard character tells the schematic editor or schematic library editor to treat that character literally, not as a wildcard (e.g., "\^test" does not look for the string test at the start of a line; it looks for the string "^test").

-

Mask Matching – enable this option to have matching text zoomed and/or dimmed in the design space according to settings on the System – Navigation page of the Preferences dialog when the Jump to Results option is enabled.

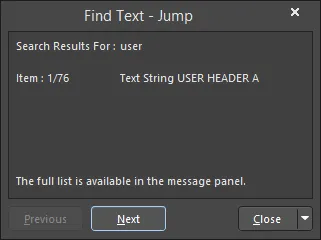

All matching text will appear listed in the Messages panel, complete with the ability to cross-probe to an instance of the searched text, directly in the design space (double-click a message entry, or right-click and choose Cross Probe from the context menu). In addition, if the Jump to Results option was enabled in the Find Text dialog and multiple instances of the text to find are returned, the Find Text - Jump dialog will be displayed and the first occurrence of the text - specified in the Text To Find field of the Find Text dialog - will be located and centered in the design space.

The Find Text - Jump dialog

The Find Text - Jump dialog is a non-modal dialog, which means you can work with Altium Designer’s interface, including objects on the schematic sheet, while the dialog is open.

Options and Controls of the Find Text - Jump Dialog

-

Previous - click this button to browse to the previous matching text item. Click repeatedly to sequentially step back through the items.

-

Next - click this button to browse to the next matching text item. Click repeatedly to sequentially step forward through the items.

As you step back and forth through the matching occurrences of found text, the upper region of the dialog will reflect the original search text and the current item being viewed in the design space in terms of the type of object (designator, net identifier, port, power port, net label), text string, or text frame) and its matching text.

-

Close - click this button to close the dialog. Click on the drop-down arrow at the right-hand side of the button to access a menu with the following options:

-

New Search - choose this command to close the dialog and open the Find Text dialog from where you can modify the search as required.

-

Close - choose this command to close the dialog and return to the design space. Alternatively, use the Esc keyboard shortcut to perform this action.

Jump to another resulting occurrence of the searched text by:

-

Using the Previous and Next buttons in the Find Text - Jump dialog.

-

Using the Edit » Find Next command (through its F3 shortcut).

-

Cross-probing from a corresponding message entry in the Messages panel.

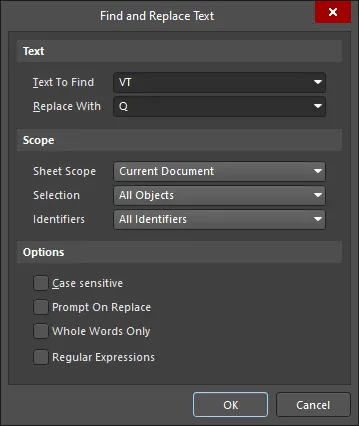

You can also find specific text, or partial text, in accordance with defined search options, then replace that text with specified new text. Choose the Edit » Replace Text command from the main menus or use the Ctrl+H keyboard shortcut to access the Find And Replace Text dialog. Use this dialog to specify the existing text to find, and the replacement text to be used, along with scoping and additional options. Once ready, click OK. All target text will be replaced, unless the Prompt On Replace option is enabled in the dialog - which will allow you to manually confirm replacement of each instance of matching text.

The Find and Replace Text dialog

Options and Controls of the Find and Replace Text Dialog

Text

-

Text To Find - use this field to enter the text string for which you want to search. Either enter the full word or search for a partial string. The latter requires the Whole Words Only option to be disabled. The string can contain the wildcard characters

? (single character) and * (any group of characters).

Wildcards are always case insensitive.

Each string searched will be added to the field's drop-down list for quick retrieval.

-

Replace With - use this field to enter the replacement text string. The text entered will completely replace the resulting text string found through the Text To Find entry and defined options.

Selective string substitutions can be performed using the {oldtext=newtext} syntax to change just a portion of the search string. For example, if you enter the string VCC into the Text to Find field and enter the string {CC=DD} into the Replace With field, all instances of the string VCC will be changed to VDD. You can use multiple sets of brackets to define complex replacements - the leftmost bracketed replacement is made first, then the next one to the right, etc.

Scope

-

Sheet Scope - use this field to determine the scope of the text search in terms of the schematic documents involved. Choose one of the following options:

-

Current Document - search the active document only. In the schematic symbol editor, a search through all part sheets contained in the document will be performed when this option is selected.

-

Project Documents - search across all schematic documents in the active project.

-

Open Documents - search across all open schematic documents, irrespective of the project they belong to.

-

Selection - use this field to further constrain the scope of the search, based on the current selection status of objects. Choose from the following options:

-

Selected Objects - limit the search to only those objects that are currently selected.

-

DeSelected Objects - limit the search to only those objects that are currently deselected.

-

All Objects - no limitation; search all objects regardless of their selection status.

-

Identifiers - use this field to further constrain the scope of the search based on the type of text-based object. Choose from the following options:

-

All Identifiers - no limitation; search across all text-based objects (text strings, text frames, pins, net identifiers, and designators).

-

Net Identifiers Only - limit the search to only net identifiers (ports, power ports, sheet entries, off sheet connectors, and net labels).

-

Designators Only - limit the search to only component designators.

Options

-

Case sensitive - enable this option to perform a case-sensitive search, meaning the target text must match the case of the search text entered into the Text To Find field. This option has no bearing on the replacement text, which simply follows the case used for the text entered into the Replace With field.

-

Prompt On Replace - enable this option to be prompted to manually confirm replacement of each instance of matching text. A Confirm dialog is used to handle each instance in turn with a final Information dialog summarizing the number of replacements made. With this option disabled, all instances of found text that match the search text will be replaced without manual confirmation required. Similarly, an Information dialog will appear to show the number of replacements made.

-

Whole Words Only - enable this option to restrict the search to whole words only. This means the search text must exist fully as is and not be part of a larger text string. For example, if this option is enabled, when looking for "cat", the software will not consider the first three letters of "category" - a valid search match. Disable this option to freely search for partial strings.

-

Regular expressions - check to search using regular expressions.

-

^ - only match when the string is at the start of a line.

-

$ - only match when the string is at the end of a line.

-

. - indicates any single character (e.g., "te.t" matches "test", "text", and "tent", but not "tet").

-

* - indicates any set of characters, including no characters (e.g., "te*" matches "text", "tent", and "te", but not "t").

-

+ - indicates any set of characters, except no characters (e.g., "te+" matches "text", and "tent", but not "te").

-

[ ] - find any of the characters enclosed in the brackets.

-

[^] - a caret at the start of a string in brackets means NOT (e.g., "[^tes]" matches any characters except t, e, or s).

-

[-] - a hyphen within a string in brackets signifies a range of characters (e.g., "[l-o]" matches the characters l, m, n, and o).

-

{ } - used to group characters or expressions. Groups can be nested with a maximum number of 10 groups in a single pattern.

-

\ - a backslash before a wildcard character tells the Schematic Editor or Schematic Library Editor to treat that character literally, not as a wildcard (e.g., "\^test" does not look for the string test at the start of a line; it looks for the string "^test").

You can only search within or across schematic documents or schematic library documents - not a combination of the two document types.

Working with Unions

A union is a collection of objects that have been grouped together. When grouped as a union, you are able to quickly select/deselect all union members, and move them all when a single member of the union is moved.

To create a union from the currently selected design objects, choose the Tools » Convert » Create Union from selected objects command from the main menus or right-click in the design space and choose the Unions » Create Union from selected objects command, from the context menu. A union will be created, with the selected objects as its members. An information dialog will confirm how many objects were added to the union.

The basic approach to moving all objects in a union is to click and hold on a member object of that union, then drag the cursor to move all in that union. However, the schematic editor also supports dragging of electrical objects (such as components, wires, ports, etc), and if this feature is enabled, then it takes precedence and overrides the move union behavior whenever you attempt to drag an electrical object.

Dragging an electrical object, such as a component, is enabled by enabling the Always Drag option on the Schematic - Graphical Editing page of the Preferences dialog. If the option is enabled, when you click and drag on an electrical object you are asking the software to attempt to maintain the current connectivity, and neatly adjust the wiring to suit as you drag.

The current state of the Always Drag option can be temporarily toggled as you work by holding the Ctrl key. If the Always Drag option is enabled and you Ctrl + click, hold and drag, the software will not attempt to maintain connectivity, instead moving the object under the cursor. In this situation, if that object is a member of a union, then all objects in the union will move. If you work with Always Drag enabled, hold Ctrl as you click and drag to move all objects in a union. Note that the Ctrl key works in both directions, if Always Drag is currently disabled, then holding Ctrl instructs the schematic editor to switch from move object behavior, to drag object behavior.

To select/deselect all objects in the union of which the object currently under the cursor is a member, right-click over an object that is a member of the required union, and choose the Unions » Select All In Union / Deselect All In Union command, from the context menu.

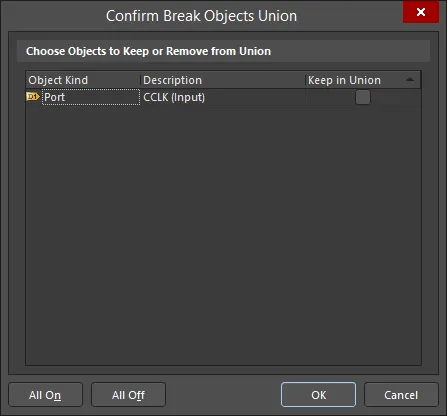

To remove one or more member objects from a specific union, choose the Tools » Convert » Break objects from Union command, from the main menus. After launching the command, the cursor will change to a cross-hair, and you will be prompted to choose the object that is to be removed from a union. Position the cursor over the required member object and click, or press Enter. The Confirm Break Objects Union dialog will appear. Use this dialog to determine which objects to remove from the union (and conversely, which objects to keep as part of that union). After clicking OK, the union's object membership will be updated accordingly.

The Confirm Break Objects Union dialog

Options and Controls of the Confirm Break Objects Union Dialog

Choose Objects to Keep or Remove from Union

-

Object Kind - shows the object type, e.g., Net Label, Bus, Hyperlink, etc.

-

Description - shows the description of the objects, e.g., height/width, designator, etc.

-

Keep in Union - enable to mark an object(s) for removal from the Union.

-

All On - click to mark all objects for removal from the Union.

-

All Off - click to deselect all objects.

Alternatively, an object can be removed from the parent union by right-clicking over the object in the required union and choosing the Unions » Break objects from Union command, from the context menu.

To break (dissolve) all unions defined for the current schematic document, choose the Tools » Convert » Break all objects Unions command, from the main menus. All unions in the design will be dissolved, with none of the former member objects remaining grouped together. An information dialog will confirm how many objects were removed, and from how many unions.