Altium Customer Success

APTUS DesignWorks drives innovation with Altimade

“The transition from concept design to detailed design to development stage to manufacturing phase must involve our clients: We walk with them along that path. We cannot design in a bubble and think about manufacturing later.”

APTUS DesignWorks Inc. is a product development and machine design services provider in Maryville, Tennessee. They recently decided to use Altimade to help them accomplish their business goals by accelerating project times and delivering quality service to their customers faster than the competition.

How APTUS DesignWorks uses Altimade to increase performance and establish a competitive advantage.

Established in 2007 as a small service company, founder Ben Nibali began the business in his home. The company has grown continuously and built a reputation for quality and professionalism. This growth led them to expand into a larger building with more employees.

Despite their best agile practices, collaboration tools, and in-house iterative processes, APTUS realized they needed external resources, such as Altimade, to provide them with substantial advantages in terms of price and lead time. This was a key decision made by the project managers. “Our ability to choose the right solution at the right time can make it look like weʼve achieved a much greater capacity than what we have in this building. That is the only way to move forward quickly,” says Ben.

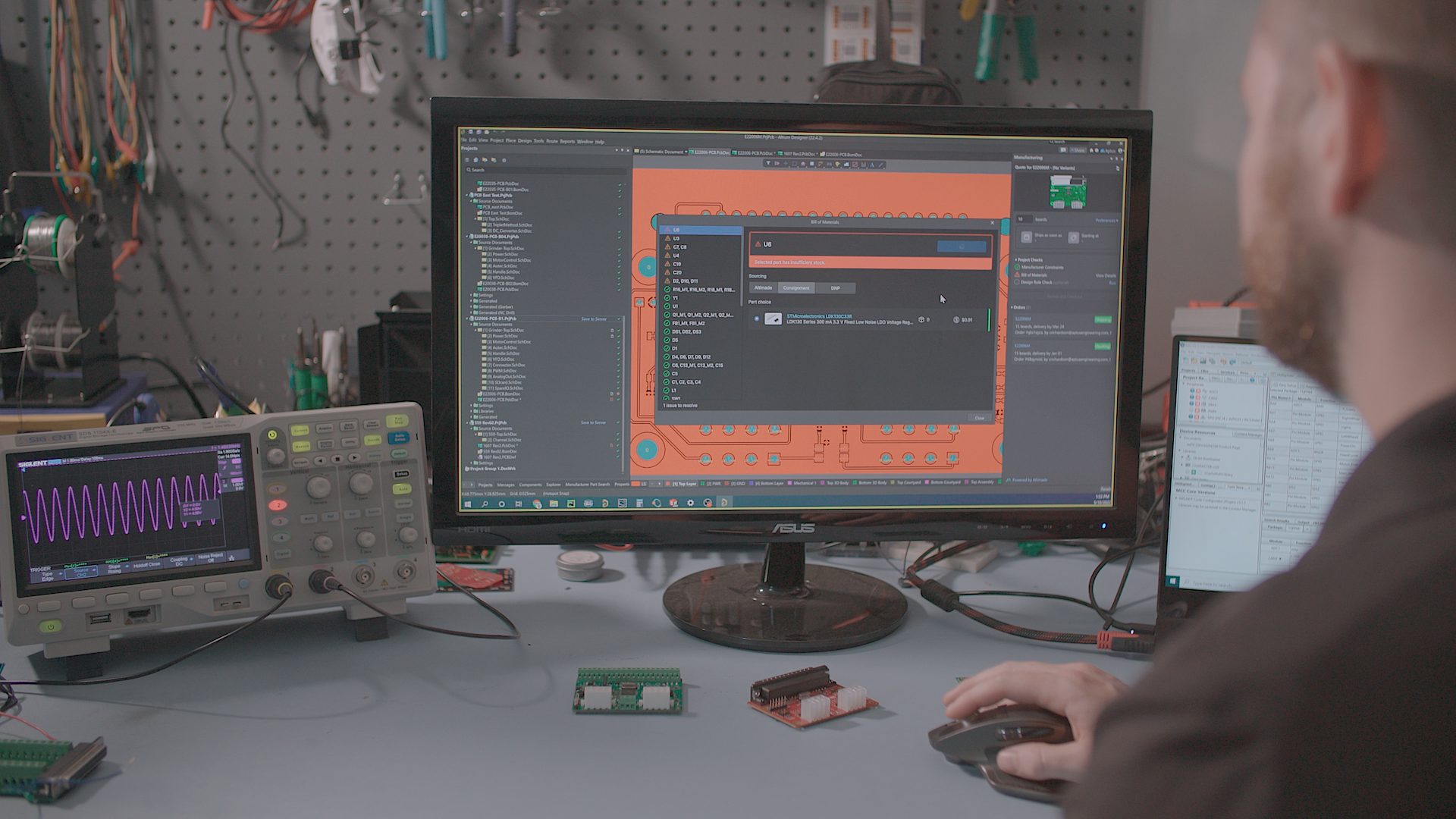

“I am the only electrical engineer on a team of mainly mechanical engineers. I do all the electrical engineering work, board design, firmware, software, and programming for the different PCBs.” says Conor Richardson, APTUS’s electrical engineer, also remembering when Altium helped them in a very challenging project: “We are particularly proud of one project with SASE, a company that manufactures concrete grinders and polishers. SASE originally had an off-the-shelf part doing all the computing functions inside a remote-controlled concrete polisher. As they were getting ready to go into production, they found that they couldn’t buy this part anymore due to supply chain issues.”

With the Supply Chain Intelligence provided by Altium, they could quickly replace this part based on stock availability. Ultimately, the product went into production on time, saving SASE money and time.

Altimade took APTUS from the manufacturing approval phase into product launch faster than they had ever before. They know that their small team has access to the same software tools that a large company has. They took advantage of these tools to drive success. “Our lead time is shorter than other companies in this field because of our tools, Altium 365 and MCAD CoDesigner, and now with Altimade. Without them, we would move much slower, Ben affirms.

The change came with Altimade

Before Altimade, Conor said they used to order the bare boards and components separately to produce a prototype. The prototype was assembled in-house or outsourced to a third party, but both methods required considerable time and resources. The first time they used Altimade, they were impressed with the ease of use and intuitive flow, as Conor explains: “We just clicked a couple of buttons, and all the parts showed up at Altimade facility; also, they were assembled there, and the process went faster than usual.”

After a successful first run with Altimade, APTUS was very satisfied with the project’s output. As Conor describes, “It came out much cheaper than we would have paid if we had taken the route we were going before. We didn’t find any problems, and the boards look fantastic!”

As one of the first companies to implement Altimade, APTUS has no regrets. “Therefore, considering manufacturing issues and the pros and cons of different methods or vendors, Altimade is the only way to move the project quickly without major delays,” concluded Ben.