ECAD-MCAD协同设计

跨越ECAD-MCAD鸿沟

您手中的电子产品是众多独立设计融合的结果。首先是您手持的外壳;在外壳内部,将有一个或多个电子电路板,在电路板上,通常会有一个运行软件的微处理器。除此之外,还可能有专门的电路部分来执行不寻常的感测或信号传输,或者可编程硬件来实现高速信号处理。 这些独立的设计 - 机械外壳、电子电路、印刷电路板、微处理器代码和可编程硬件 - 每一个都使用自己的设计范式,每个设计都通过其自己的设计编辑器精心打造。 多年来,这些独特的设计领域变得更加紧密相连。这种紧密连接对于确保最终产品的所有方面正确地相互配合至关重要,为我们带来了那些易于使用且熟悉的产品,如我们的手机、笔记本电脑和电动汽车。 ECAD到MCAD的分隔是最后一个需要跨越的设计领域。通过在中间文件格式中保存文件来桥接它们是可行的,但这种方法正变得不够充分 - 易于出错、功能有限,且难以协调和管理。 需要的是一种3D PCB设计编辑器,能够直接将设计更改通信到各种机械设计包。这一挑战正在被Altium的技术 - Altium MCAD CoDesigner 解决,它将ECAD和MCAD设计领域结合在一起。 - 查看CoDesigner新功能页面,以了解最新的增强功能。该页面还详细介绍了每个CoDesigner版本支持的MCAD软件版本。 - 如果您更喜欢通过观看学习,您可能想查看ECAD-MCAD CoDesign操作视频页面。 - 如果您有关于使用CoDesigner的具体问题而在此未找到答案,请查看Altium知识库。知识库由Altium支持人员开发和维护,他们是解决您设计挑战的一线专家。知识库包括其自己的 搜索功能,使用它可以快速检查可能的解决方案。 - 请参考右侧窗格中的注意,了解哪些功能将在您安装的MCAD CoDesigner中可用。了解PCB编辑器中的3D设计功能

如果您正在使用CoDesigner与您的机械工程师来回传递电路板设计,您会想了解Altium PCB编辑器中可用的3D设计功能。除了创建或导入组件的3D模型,您还可以导入产品外壳并执行3D间隙检查(将光标悬停在图像上)。 对于刚性-柔性设计,电路板可以在PCB编辑器中交互式折叠,这是执行折叠板最终状态下的间隙检查的理想方式。 如果您的MCAD软件还不支持CoDesigner,您可以将ECAD板导出为STEP或Parasolid格式,准备加载到您的MCAD软件中。 ► 了解更多关于在Altium Designer中布局您的PCB使用Altium CoDesigner进行直接的ECAD-MCAD设计

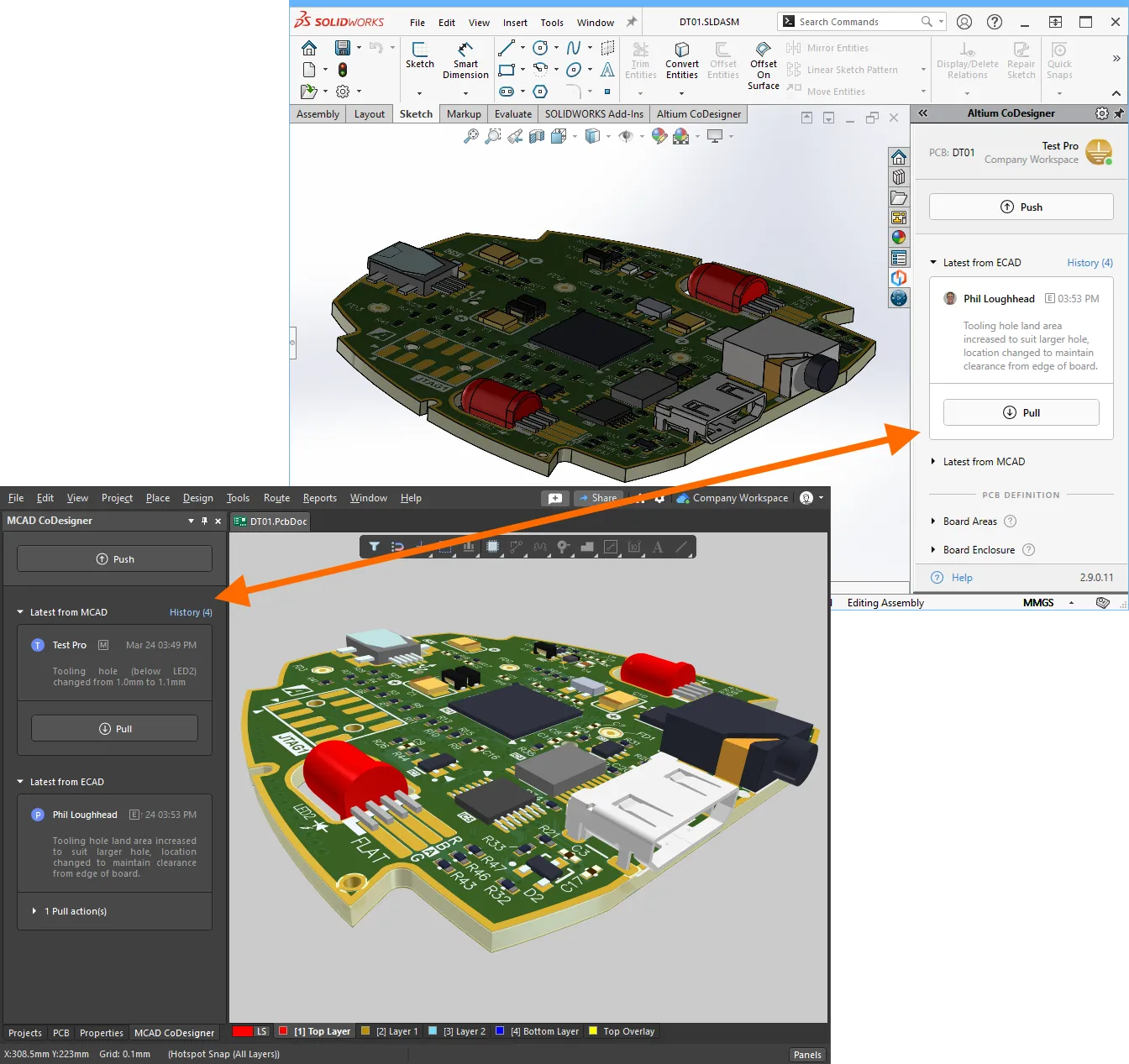

在电子和机械设计领域之间工作带来了独特的挑战。小型且复杂的产品外壳内部容纳着多个不规则形状的印刷电路板 - 要成功设计这些产品,ECAD和MCAD设计师必须能够在他们的设计领域之间流畅地传递设计更改。

在不同设计软件之间传递复杂和详细的设计更改,远不止于能够以另一种格式保存数据。电子和机械设计团队独立工作,并且需要能够在设计过程的任何点选择性地传递设计更改。

Altium CoDesigner支持这一点,提供直接的ECAD到MCAD协同设计。

► 了解更多关于安装和配置Altium MCAD CoDesigner的信息

► 了解更多关于使用Altium MCAD CoDesigner进行直接ECAD-MCAD设计的信息

连接ECAD和MCAD设计组件

每个MCAD软件包都以其自己的方式表示和存储其设计对象,CoDesigner必须能够读写所有这些格式。Altium CoDesigner的默认方法是以标准Parasolid格式来回传递组件作为3D模型,确保设计在ECAD和MCAD领域中都是机械精确的。

每个MCAD软件包都以其自己的方式表示和存储其设计对象,CoDesigner必须能够读写所有这些格式。Altium CoDesigner的默认方法是以标准Parasolid格式来回传递组件作为3D模型,确保设计在ECAD和MCAD领域中都是机械精确的。

然而,组件远不止其物理外壳那么简单。例如,在PCB领域,它们还包含丝印和贴片细节、与其原理图符号的链接,以及将它们与供应链相连的参数信息。在理想的世界中,ECAD和MCAD设计师可以各自从他们自己的库中放置一个原生设计组件,并将他们的原生组件相互链接。CoDesigner通过共享的Altium 365工作空间支持这种链接。

► 了解更多关于 链接ECAD和MCAD设计组件的信息

同步刚柔板

同步刚柔板

或许,最难以生产的印刷电路板设计是刚柔板设计。设计刚柔电路非常是一个电机工程过程,因为刚柔板必须设计成可以在产品组装时被组装并折叠进机壳内。到目前为止,这个紧密的电机设计挑战通过制作一个机械模型来解决,也就是所谓的纸娃娃剪裁。

Altium CoDesign 帮助解决了这个挑战,提供了在ECAD和MCAD领域之间传输折叠刚柔设计的能力。

► 了解更多关于同步刚柔板的信息

同步多板组装

电子设备通常作为多个电路板的组合体构建,这些电路板在机械外壳内巧妙地形状设计和排列,以提供功能性产品。虽然PCB将在ECAD中设计,但定义每个板的形状然后将完成的PCB定位在外壳内的过程,最好在MCAD中执行。

电子设备通常作为多个电路板的组合体构建,这些电路板在机械外壳内巧妙地形状设计和排列,以提供功能性产品。虽然PCB将在ECAD中设计,但定义每个板的形状然后将完成的PCB定位在外壳内的过程,最好在MCAD中执行。

为此,您需要能够在ECAD和MCAD之间来回同步单个板和整个PCB组装(包括外壳)。

► 了解更多关于 同步多板组装的信息

同步线束设计项目(焦点Beta)

同步线束设计项目(焦点Beta)

多板产品中的电路板使用线束将PCB连接在一起,同时也连接各种用户交互的按钮、显示器和控制器。

Altium MCAD CoDesigner in PTC Creo 现在支持在ECAD和MCAD之间同步线束设计,将连接器、接头、连接性和拓扑从ECAD传输到MCAD;并将线束元素的物理长度从MCAD传回ECAD。

► 了解更多关于同步线束设计项目

ECAD-MCAD 视频教程

你是喜欢通过观看视频来学习的人吗?那么你可能会想要查看不断增长的ECAD-MCAD视频教程集合。每个视频都快速概述了如何解决特定的设计挑战,例如在MCAD中塑造PCB,或在设计交换期间维持MCAD约束。

► 观看 ECAD-MCAD视频教程

接下来去哪里?

如果您是Altium软件的新手,您可能会喜欢从从概念到完成的教程开始 - 围绕一个简单的九元件电路,您将从一个空白的原理图开始,最终得到PCB以及制造电路板所需的文件。像Altium的所有设计技术一样,编辑器旨在易于学习和使用。广泛使用了上下文敏感的右键菜单,而且到处都可以使用上下文敏感帮助(F1)和命令中的快捷键列表(Shift+F1)。

否则,您可能会想查看以下文章:

AI 翻译

AI 翻译